Infrared ray gas analyzer using photon crystal optical fiber as gas chamber

A technology of photonic crystal fiber and gas analyzer, which is applied in the direction of material analysis, analysis materials, instruments, etc. through optical means, can solve the problems of large volume and bulkiness of infrared gas analyzer, and achieve light weight, high measurement accuracy, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

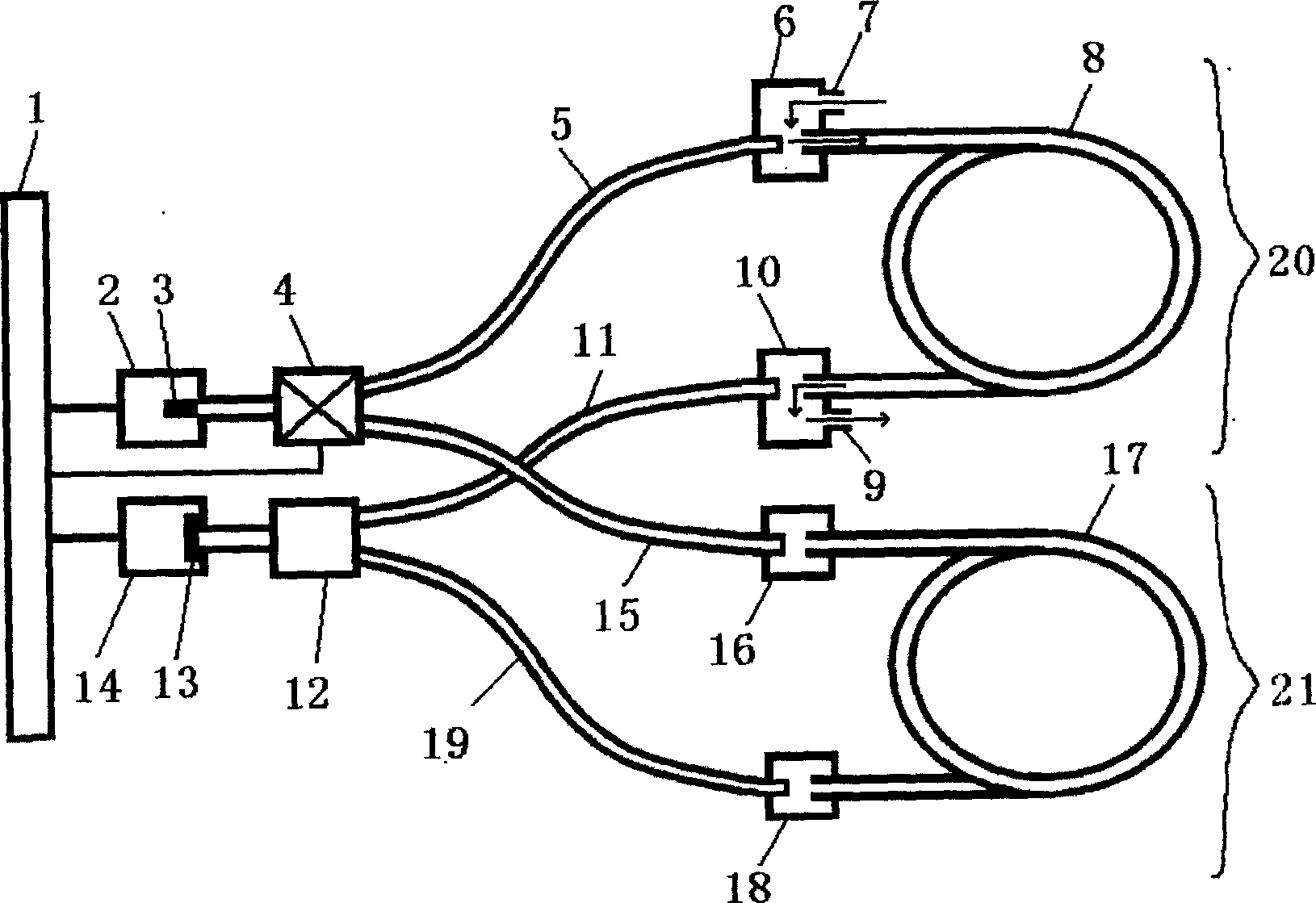

[0014] Such as figure 1 As shown, the gas concentration detection device includes a measurement path 20 and a reference path 21 .

[0015] Among them, one end of the measurement path photonic crystal fiber 8 in the measurement path 20 is connected to the inlet connection unit 6 and communicates with the inlet connection unit 6 , and the other end is connected to and communicates with the outlet connection unit 10 . The air intake connection unit 6 is hollow and is provided with an air intake 7 . The air outlet connection unit 10 is hollow and is provided with an air outlet 9 . The gas to be measured can pass into the photonic crystal fiber 8 of the measurement path through the air inlet 7, and be discharged through the gas outlet 9 through the photonic crystal fiber 8 of the measurement path, so that the photonic crystal fiber 8 of the measurement path is filled with the gas to be measured. One end of the measurement path input optical fiber 5 is connected to the intake conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com