Method of realizing high precision phase shifting of ferr ite phase shifting device

A ferrite and phase shifter technology, which is applied in waveguide devices, electrical components, circuits, etc., can solve the problems of difficult to achieve high-precision numerical control phase shifting, complex structure of phase shifters, difficulty in debugging and manufacturing, etc. , to achieve high-precision phase shifting, reduce manufacturing difficulty, and increase switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The maximum required phase shift step is δ=1°.

[0053] The maximum phase shift value of the first-stage ferrite excited by magnetic flux cmax =30°, the above phase shift accuracy requirements can be met.

[0054] According to relation Determine that the minimum value of n is 4.54, and round n to 5, that is, five sections of ferrite are required;

[0055] According to the relationship (1), (2) and (3), the nominal phase shift value of each section of ferrite for the remaining 4 sections of saturated digital excitation can be determined i They are 25°, 51.3°, 94°, 184.5° in turn.

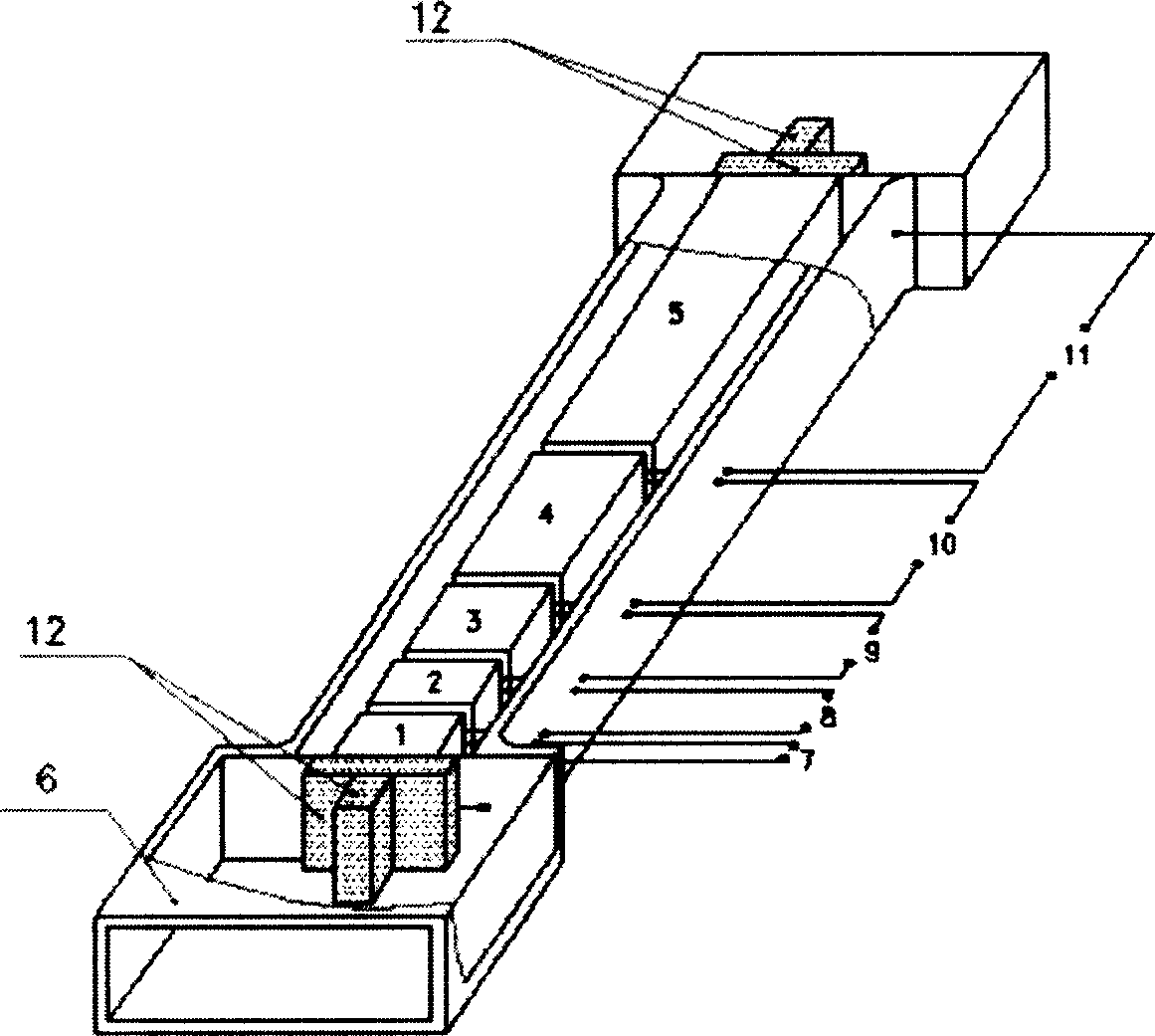

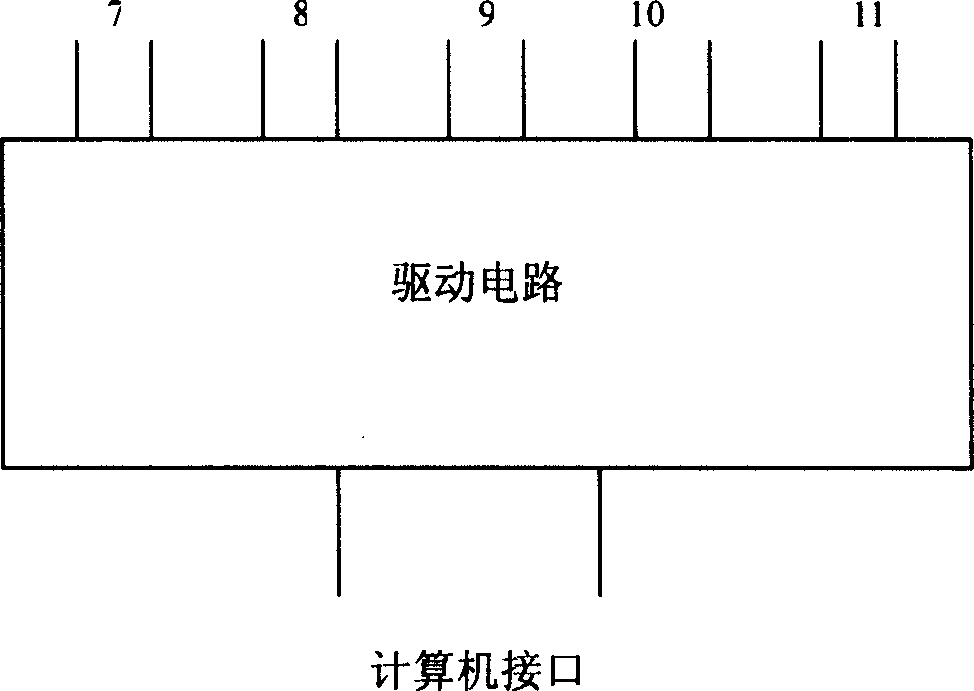

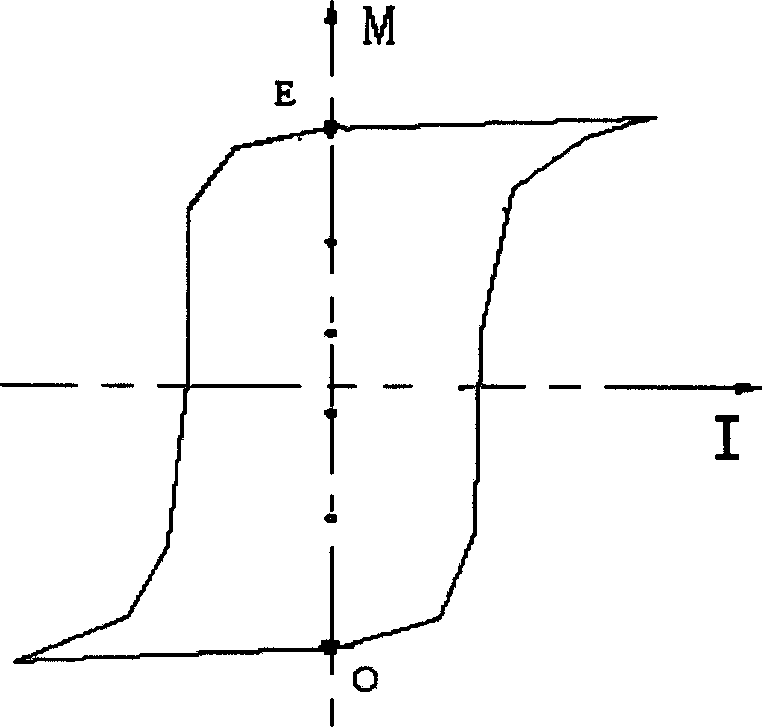

[0056] The structure of the phase shifter in this embodiment is as follows figure 1 shown. Among them, 1 represents a ferrite ring rod with a maximum phase shift value of 30°, and the ring rod of this section is magnetized according to the magnetic flux excitation method. 2, 3, 4, and 5 are ferrite ring rods with different lengths, which are used to generate four phase shift values...

Embodiment 2

[0085] The maximum required phase shift step is δ=4°.

[0086] The maximum phase shift value of the first-stage ferrite excited by magnetic flux cmax =57°, the above phase shift accuracy requirements can be met.

[0087] According to relation Determine that the minimum value of n is 3.58, and round n to 4, that is, four sections of ferrite are required;

[0088] According to the relationship (1), (2) and (3), the nominal value of the phase shift of each segment of the ferrite for the remaining 3 segments of saturated digital excitation can be determined i They are 51°, 96.4°, and 187.2° in turn.

[0089] In this embodiment, the superimposition mode of phase shift of each section of ferrite is the same as that in Embodiment 1. Table 2 is an excerpt of the phase-shifting state test results of this embodiment. The data in Table 2 shows that the phase-shifting step amount is ≤4°.

[0090] CNC binary code

Phase shift value

CNC binary code

Phase shift...

Embodiment 3

[0105] The maximum required phase shift step is δ=1°.

[0106] The maximum phase shift value of the first-stage ferrite excited by magnetic flux cmax =30°, the above phase shift accuracy requirements can be met.

[0107] According to relation Determine that the minimum value of n is 4.54, and round n to 5, that is, five sections of ferrite are required;

[0108] According to the relationship (1), (2) and (3), the nominal phase shift value of each section of ferrite for the remaining 4 sections of saturated digital excitation can be determined i 30°, 60°, 110°, 160° in turn.

[0109] In this embodiment, the superimposition mode of phase shift of each section of ferrite is the same as that in Embodiment 1.

[0110] The test result of the phase shifting accuracy in this embodiment is: the phase shifting step is less than 1°

[0111] In phase shifter engineering, when the saturated digital excitation method is used alone, for a four-bit saturated digital phase shifter, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com