Green sheet, plasma display panel and method for manufacturing plasma display panel

A display panel and plasma technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as difficulty in forming electrodes and increase in electrode resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

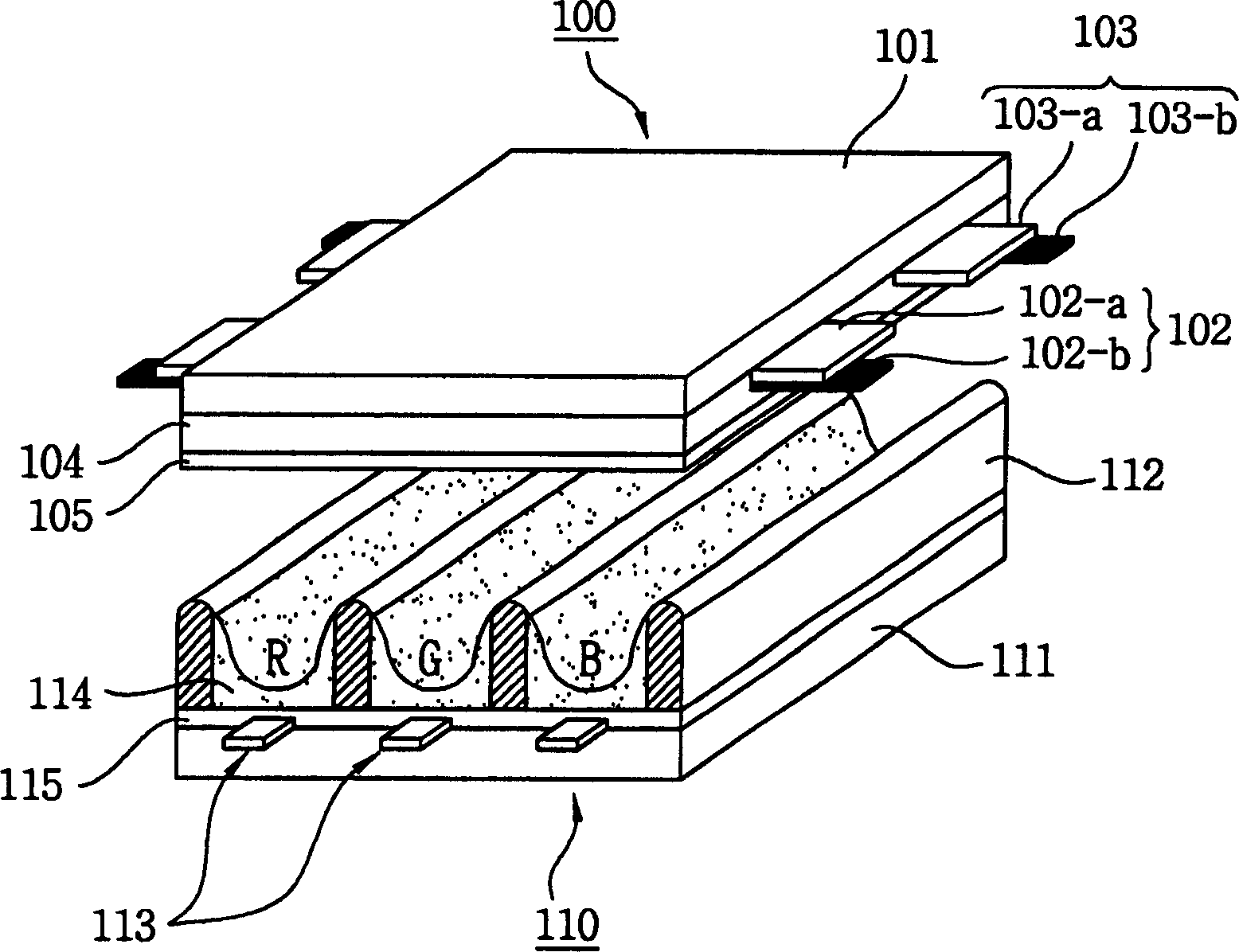

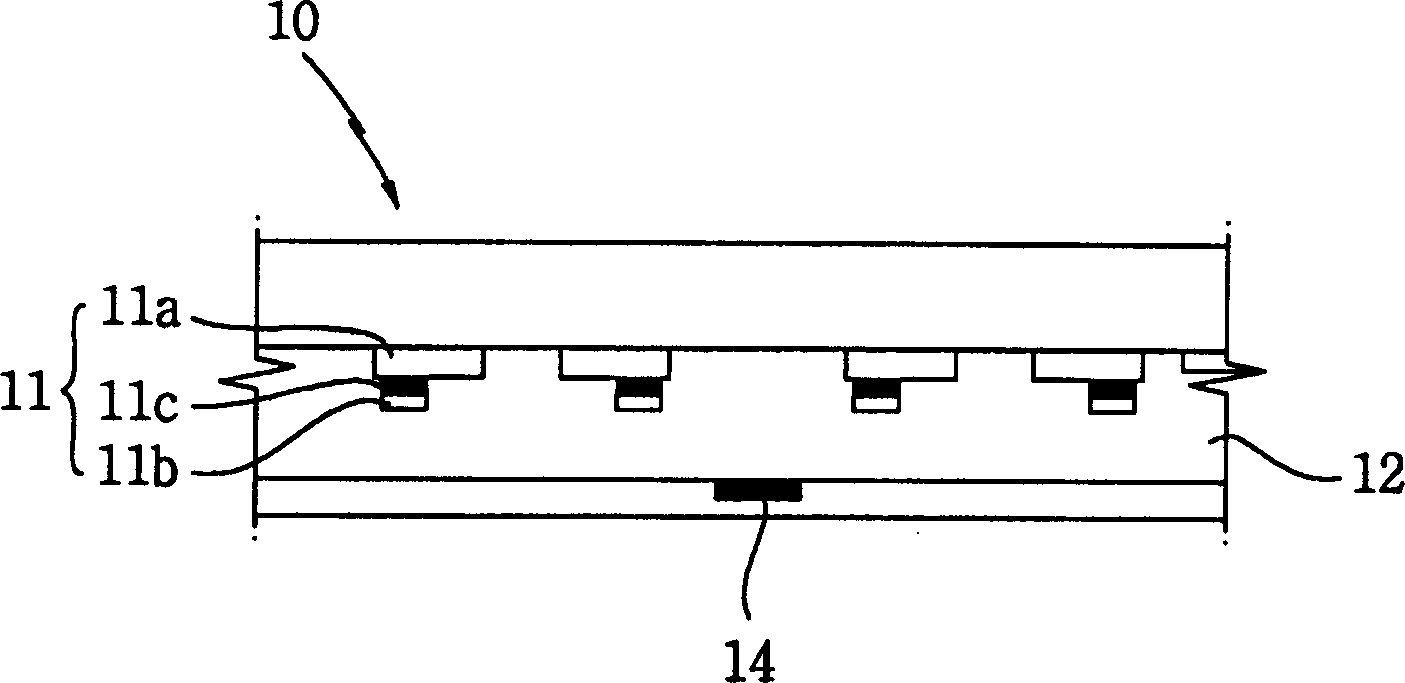

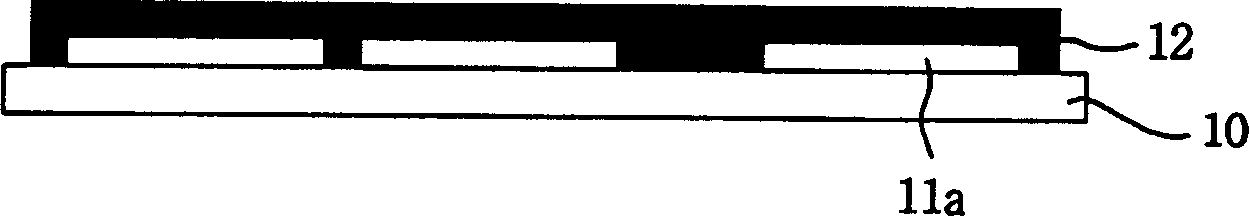

[0041] Embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

[0042] A green sheet for a plasma display panel (PDP) according to the present invention includes a base film, an electrode film including nano conductive particles formed on the base film, and a cover film formed on the electrode dry film.

[0043] The nano conductive particles are nano Ag particles.

[0044] The diameter of the nano conductive particles is greater than or equal to 700nm and less than or equal to 1100nm.

[0045] The green flakes further include a black layer film formed between the base film and the electrode film and including a sintered material.

[0046] The sintered material is glass frit.

[0047] The weight percentage of the glass frit is greater than or equal to 15wt% to less than or equal to 25wt% of the black film.

[0048] The green flake further includes a photoresist layer formed between the electrode film and the cap film....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap