Subaqueous architecture construction method

A construction method and building technology, which can be used in construction, underwater structures, water conservancy projects, etc., can solve the problems of island wall collapse, fill and scour leakage, and accidents, and achieve the effect of ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

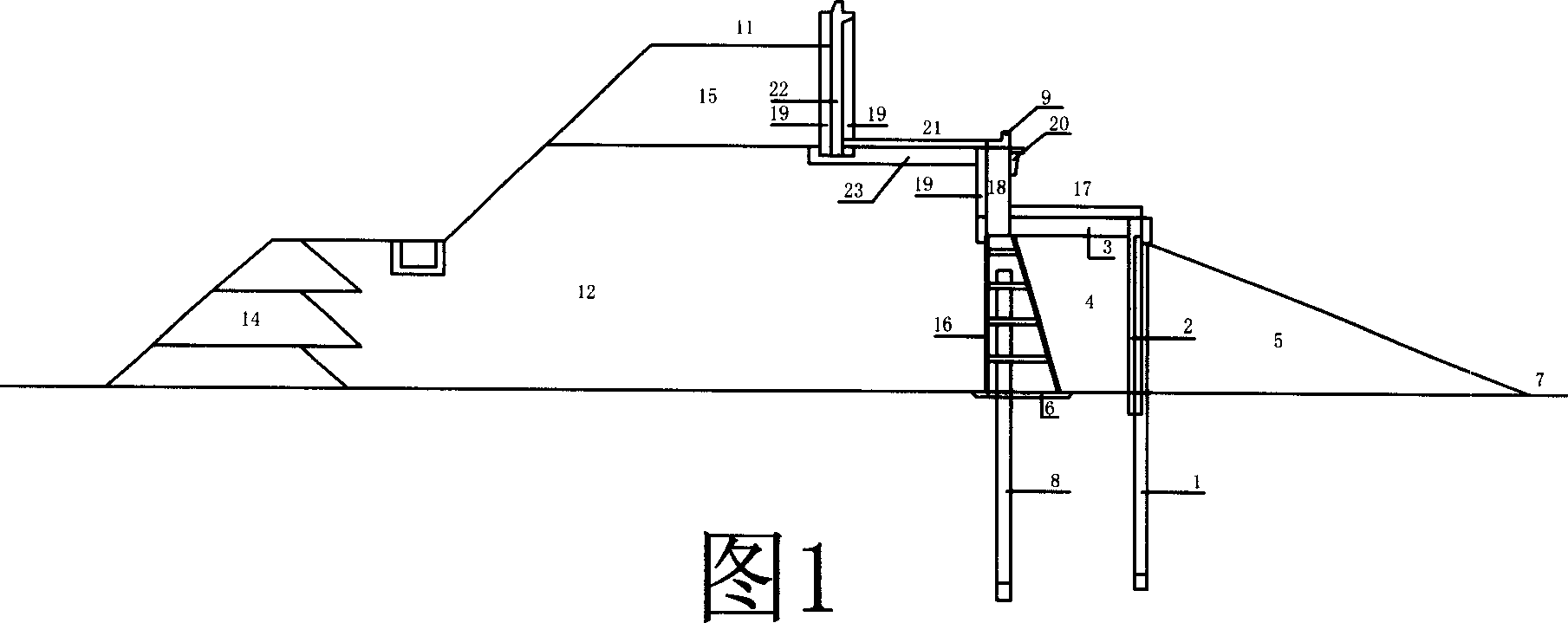

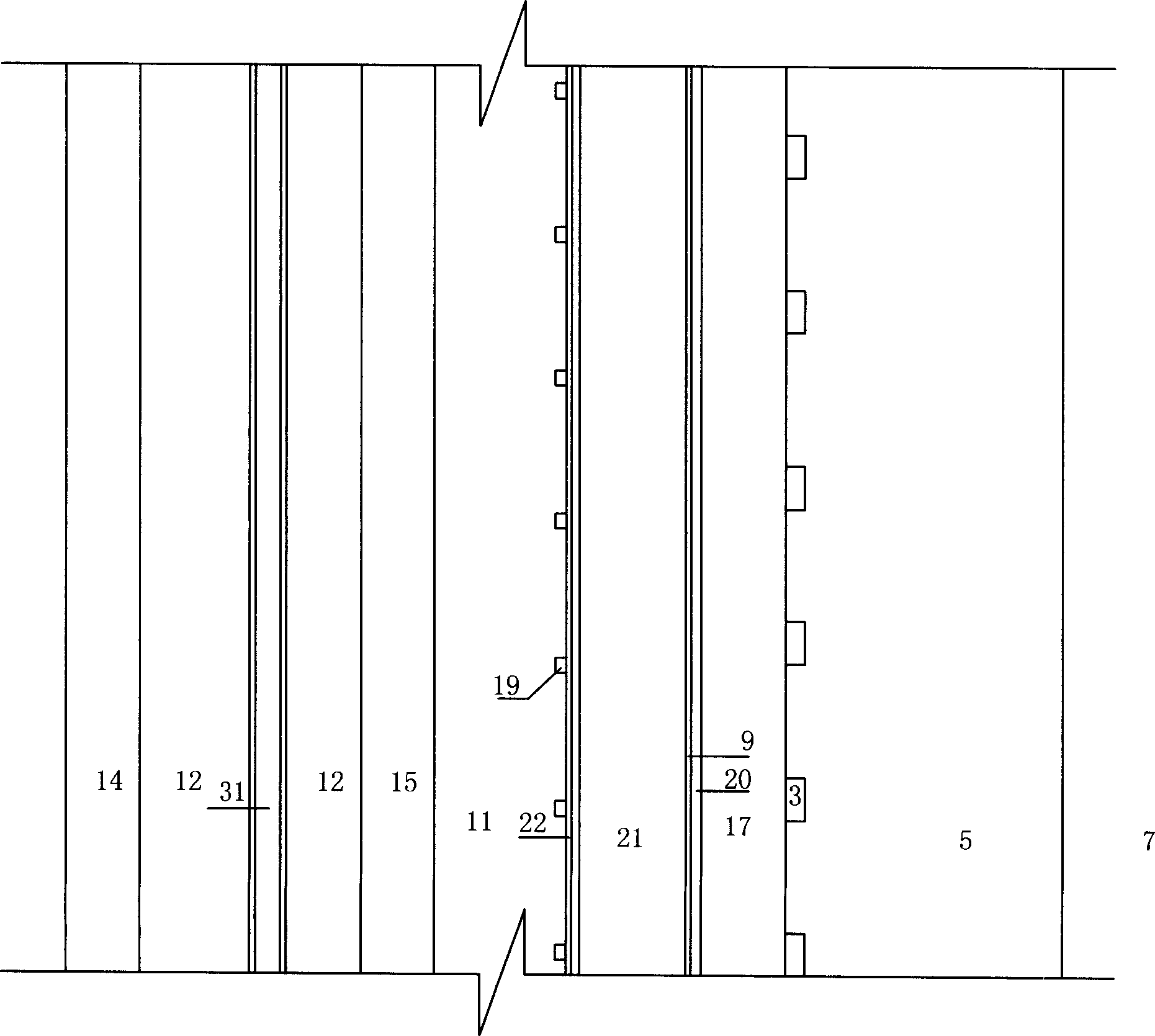

[0019] The construction steps of the present invention are as follows: a. Lower the foundation pile 8 into the water, and sprinkle a crushed stone cushion 6 on the surface of the underwater foundation of the foundation pile 8, b. Cover the open caisson of the slab joint 16 with steel cage On the piles and form an extension; c. In-situ concrete is poured underwater to the top of the slab in the middle gap of the opening caisson of the slab joint 16 to form an underwater impervious wall; d. Piles are placed outside the slab joint 16 The plate joint 1 and the ribbed baffle 2 form another wall, the width of the two walls is the length of the positioning beam 3; e. The positioning beam 3 is buckled on the two walls. f. Fill the frame composed of the slab joint 16, the pile plate joint 1 and the ribbed baffle 2 with rubble 4 to be flush with the top of the positioning beam 3 to form a subgrade platform 17; g. On the water surface of the subgrade platform 17 The slope protection rubble 5...

Embodiment 2

[0021] The construction steps of the present invention are as follows: a. Lower the foundation pile 8 into the water, and sprinkle a crushed stone cushion 6 on the surface of the underwater foundation of the foundation pile 8, b. Cover the open caisson of the slab joint 16 with steel cage The foundation pile 8 forms a ring frame; c. In the middle gap of the open caisson of the slab joint 16 under water, cast concrete to the top of the slab to form an underwater impervious wall; d. Outside the slab joint 16 The other wall is composed of the pile-slab joint 1 and the ribbed baffle 2. The width of the two walls is the length of the positioning beam 3; e. The positioning beam 3 is buckled on the two walls. f. Fill the frame with rubble 4 flush with the top of the positioning beam 3 to form the subgrade platform 17; g. Throw the slope protection rubble 5 outside the subgrade platform 17 to form the first step; h. On the slab joint 16 The lower wall 18 of cast-in-place reinforced concre...

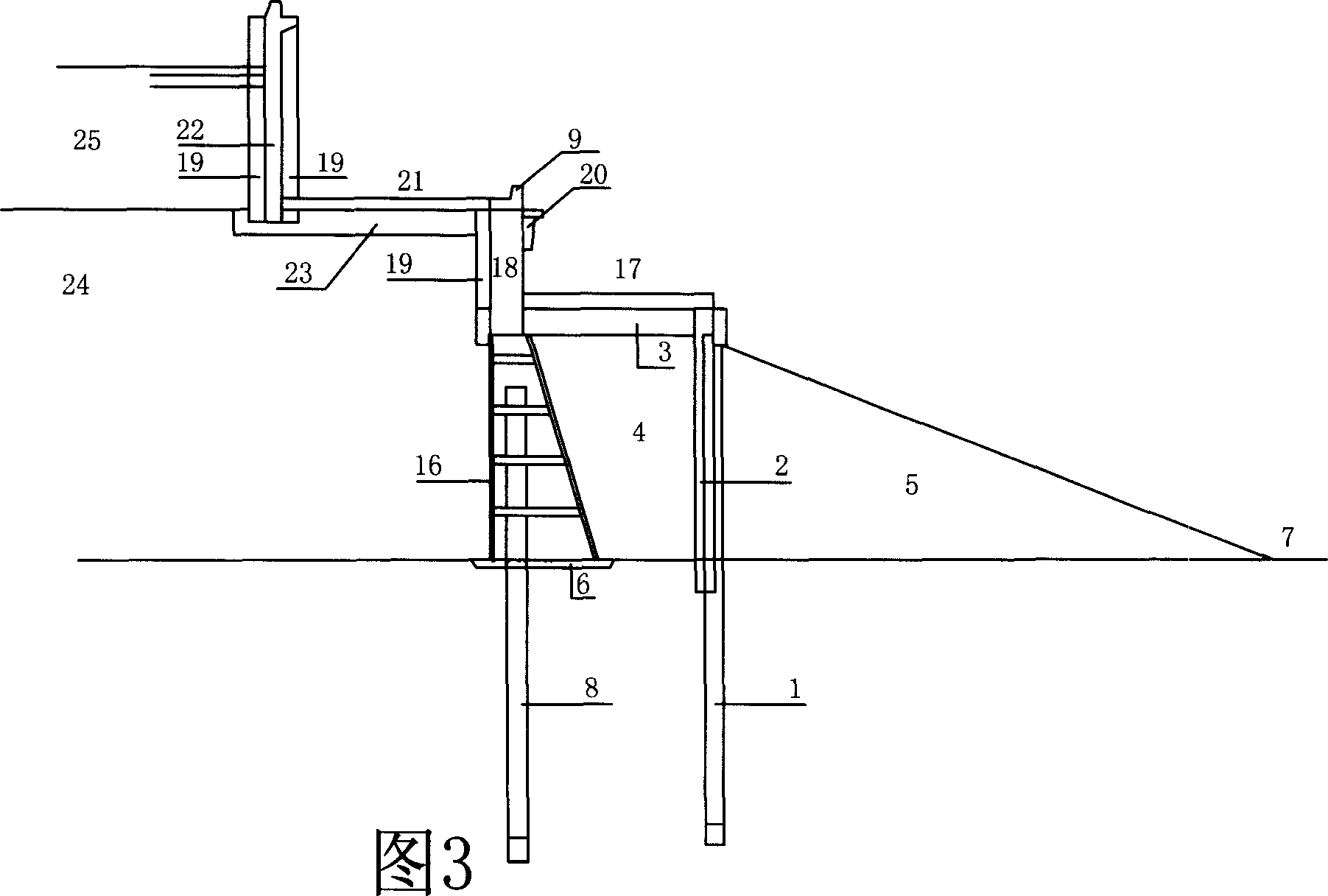

Embodiment 3

[0023] The construction steps of the present invention are as follows: a. Lower the foundation pile 8 into the water, and sprinkle a crushed stone cushion 6 on the surface of the underwater foundation of the foundation pile 8, b. Cover the open caisson of the slab joint 16 with steel cage The piles form a ring frame; c. In-situ concrete is poured underwater to the top of the slab in the middle gap of the open caisson of the slab joint 16 to form an underwater impervious wall; d. Piles are placed outside the slab joint 16 The plate joint 1 and the ribbed baffle 2 form another wall, the width of the two walls is the length of the positioning beam 3; e. The positioning beam 3 is buckled on the two walls. f. Fill the frame with rubble 4 flush with the top of the positioning beam 3 to form the subgrade platform 17; g. Throw the slope protection rubble 5 on the water facing surface of the subgrade platform 17 to form the first step; h. The cast-in-situ reinforced concrete lower wall 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com