Method for manufacturing non-oriented electromagnetic steel sheet, and raw material hot rolling steel sheet

An electromagnetic steel plate, non-directional technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

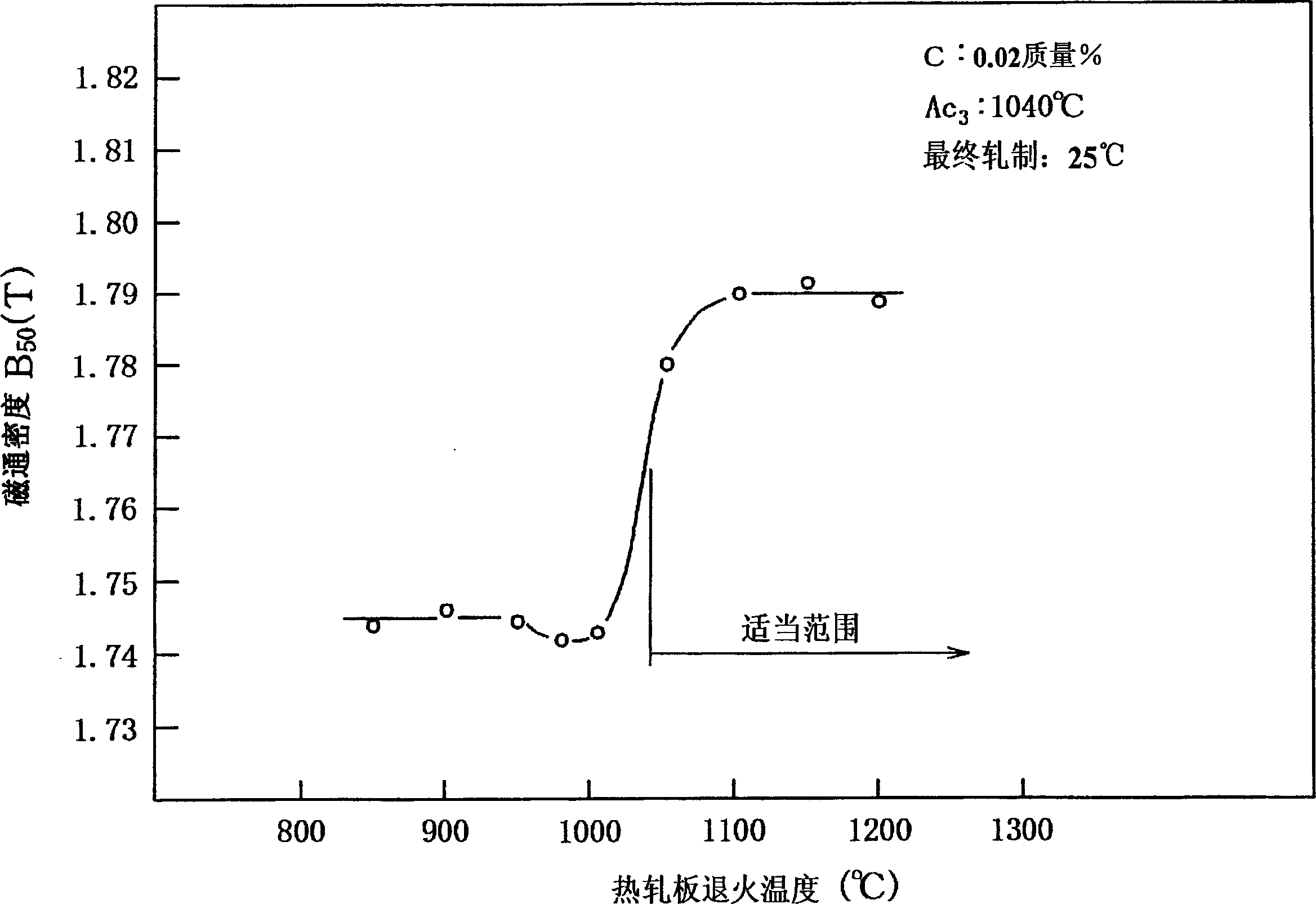

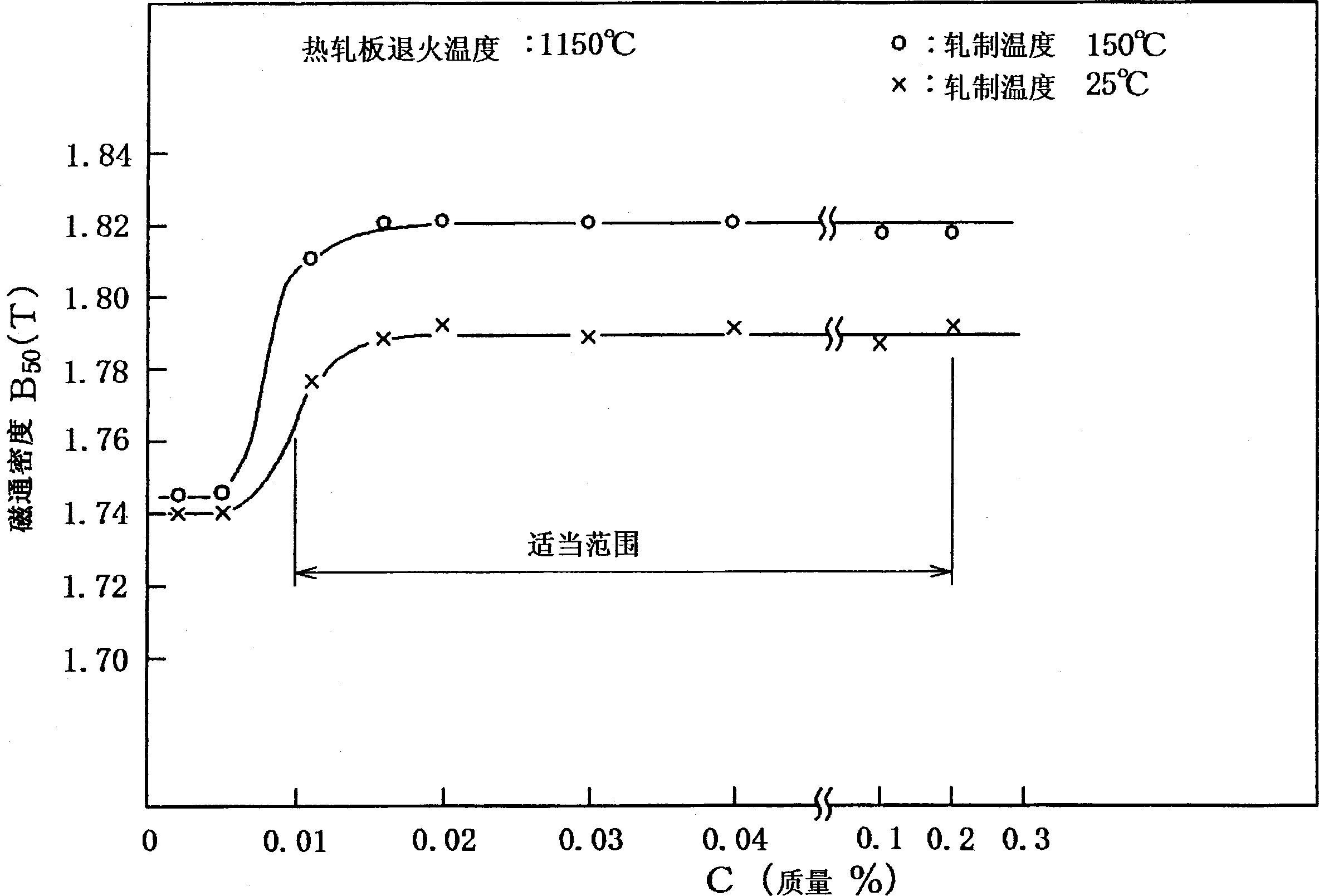

[0166] The steel having the composition shown in Table 1 was smelted by converter blowing and degassing, and after continuous casting, the obtained slab was heated at 1200° C. for 1 hour, and then hot rolled to a thickness of 2.6 mm. The final temperature of hot rolling was 830°C, and the coiling temperature was 610°C.

[0167]then. After hot rolling and annealing under the conditions shown in Table 2, final cold rolling (25°C) or final warm rolling (50-350°C) to plate thickness: 0.5mm, decarburization annealing and final annealing are performed to obtain Non-oriented electrical steel sheet. Except for No. 44 (material containing excess S), the value of the parameter (P+100×S+300×Se) was 0.5 or less.

[0168] Table 2 shows the results of the examination of the magnetic properties of the electrical steel sheets thus obtained.

[0169] In addition, magnetic measurement was performed using the Epstein test piece of 25 cm. In addition, A in the table c3 The point is obtained ...

Embodiment 2

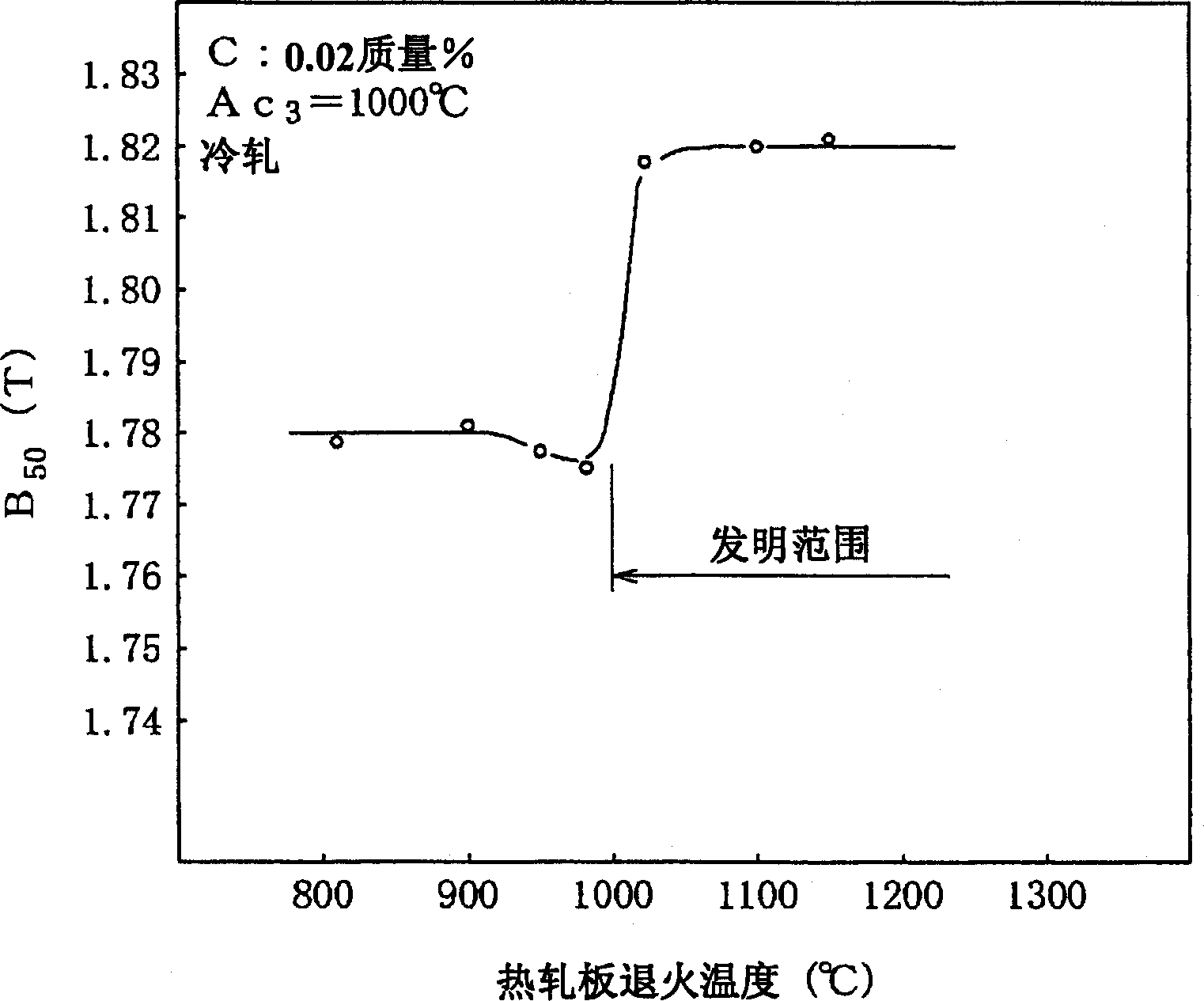

[0179] For the steel with the composition shown in Table 3, after hot rolling was carried out under the same conditions as in Example 1, the hot-rolled sheet was annealed under the conditions shown in Table 4, and then the final cold rolling (25° C.) or the final warm rolling was performed. (50-350° C.) to a plate thickness of 0.5 mm, decarburization annealing and final annealing are performed to become a non-oriented electrical steel sheet. The value of the parameter (P+100*S+300*Se) is 0.21.

[0180] The magnetic properties and A c3 Table 4 shows the results of the same examination as in Example 1.

[0181]

mark

Composition (mass%)

Ac 3 point

(℃)

C

Si

mn

P

S

Al

N

Sb

sn

Ni

co

Cr

Cu

A

0.0200

1.00

0.21

0.011

0.0020

tr

0.0020

tr

tr

tr

tr

tr

tr

104...

Embodiment 3

[0189] For the steel composed of the composition shown in Table 5, after hot rolling was carried out under the same conditions as in Example 1, the hot-rolled sheet was annealed under the conditions shown in Table 6, and then the final cold rolling (25° C.) or After final warm rolling (50 to 350° C.) to a plate thickness of 0.5 mm, decarburization annealing and final annealing were similarly performed under the conditions shown in Table 6 to obtain a non-oriented electrical steel sheet. In addition, the average cooling rate in the 800-500°C region of cooling after the hot-rolled sheet annealing was 60°C / s.

[0190] The magnetic properties and A c3 Table 6 shows the results of the same examination as in Example 1. In addition, after the magnetic measurement, the aging treatment was performed at 150° C. for 100 h, and then the magnetic measurement was performed again. The obtained measurement results are recorded in Table 6 together.

[0191]

steel mark

Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com