Pipe end seal method

A pipe end and sealing technology, which is applied in the field of sealing and welding after bending the pipe end inward

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention bends the pipe end inward before sealing the pipe end, and then seals the pipe without grinding. The pipe produced in this way saves cost.

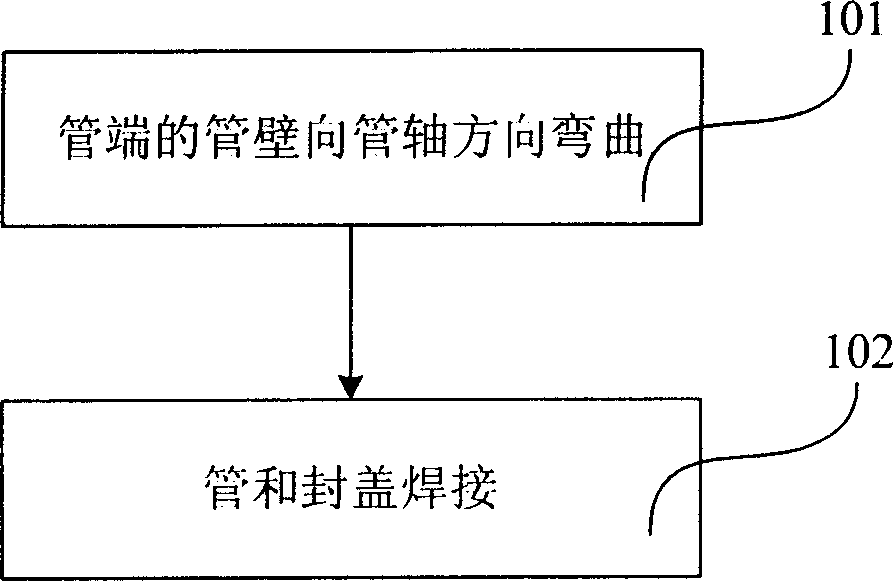

[0026] Such as image 3 Shown, be the flow chart of pipe end sealing method of the present invention, comprise the steps:

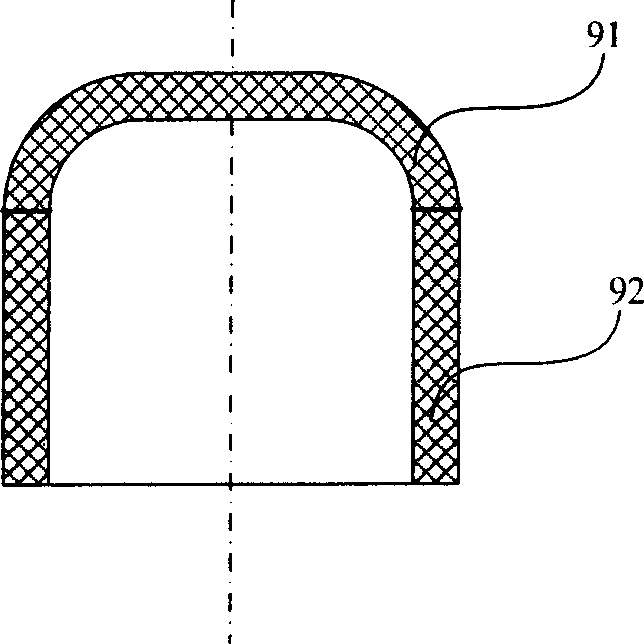

[0027] Step 101, bending the circumference of the pipe wall of the pipe port to the direction of the pipe axis to form a smooth curved surface on the outside of the pipe, and the section of the pipe end and the axis form an included angle θ;

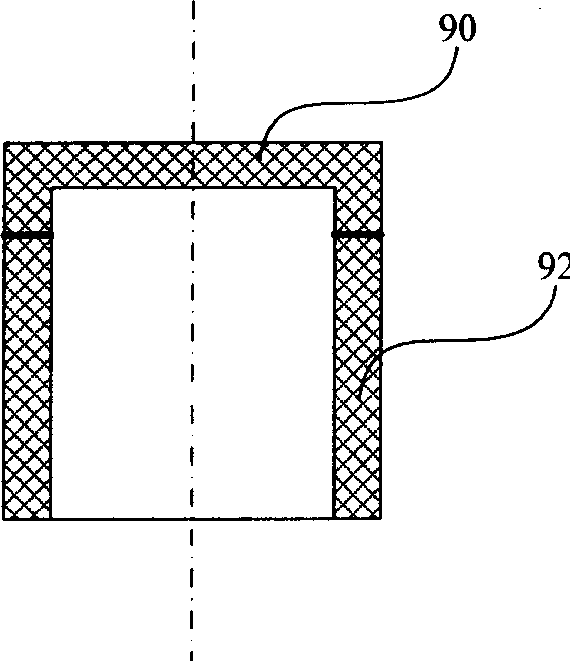

[0028] join Figure 4 As shown, it is a structural schematic diagram of the present invention, the angle θ between the section 11 of the pipe end 10 of the pipe 1 and the axis can be between 15 degrees and 80 degrees, depending on the needs of manufacturing; the pipe 1 can be a round pipe Or an elliptical tube, there may be a threaded connection hole 20 on the cover 2, and the tube 1 and the cover 2 are steel or stainless steel or brass or aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com