Air pressure engine

An engine and air pressure technology, which is applied in the direction of machines/engines, rotary piston engines, rotary or swinging piston engines, etc., can solve the problems of air pollution, high maintenance costs, and low work efficiency, and achieve no pollution to the environment and low maintenance costs , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

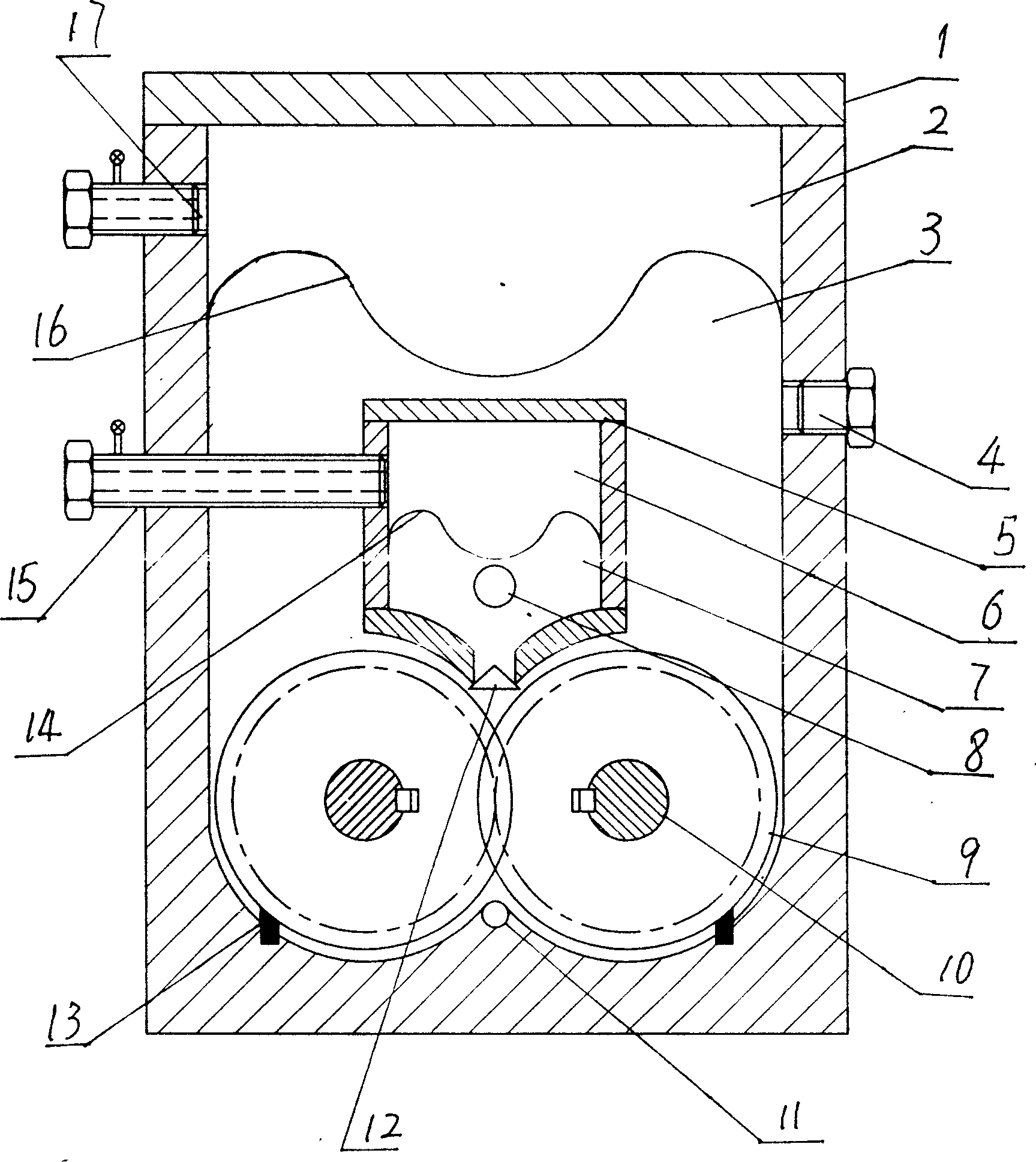

[0008] The present invention is made up of casing 1, case cover, gear 8 etc. The specific structure is as figure 1 , the upper part of the box body 1 is cast with a high-pressure chamber 2, and the high-pressure oil chamber 3 is located under the high-pressure chamber 2. In order to isolate the contact between the gas and the oil, a layer is set between the high-pressure oil chamber 3 and the high-pressure chamber 2 Air pressure diaphragm 13. An inner box body 4 is installed in the box body 1, and the inner box body 4 is located at the bottom of the high-pressure oil chamber 3. The inner box 4 is divided into two chambers, the upper chamber is the low-pressure chamber 5, and the lower chamber is the low-pressure oil chamber 6. In order to isolate the contact between the gas and the oil, an air pressure chamber is installed between the low-pressure cha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap