Light tunnel of dlp projection system

A digital light processing and projection system technology, applied in the field of light tunnels, can solve the problems of reducing surface light, reducing image quality, poor reflection angle of reflectors, etc., to achieve uniform surface light and improve image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

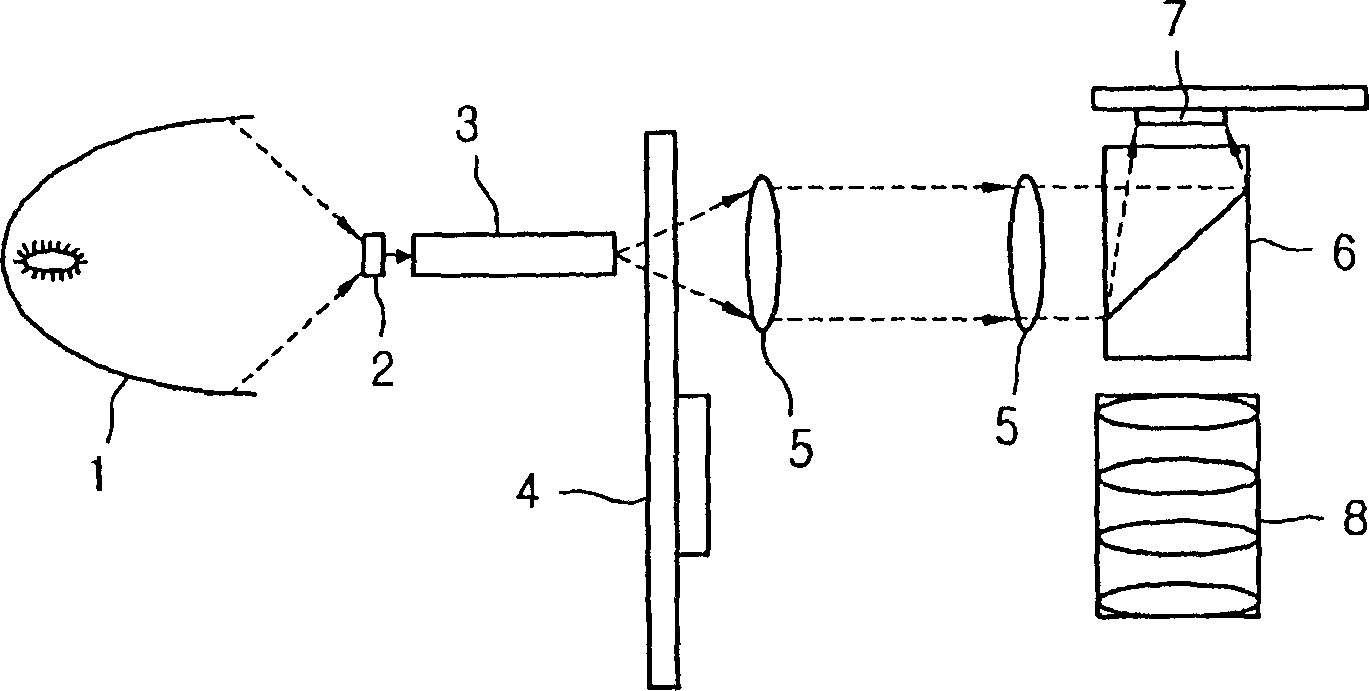

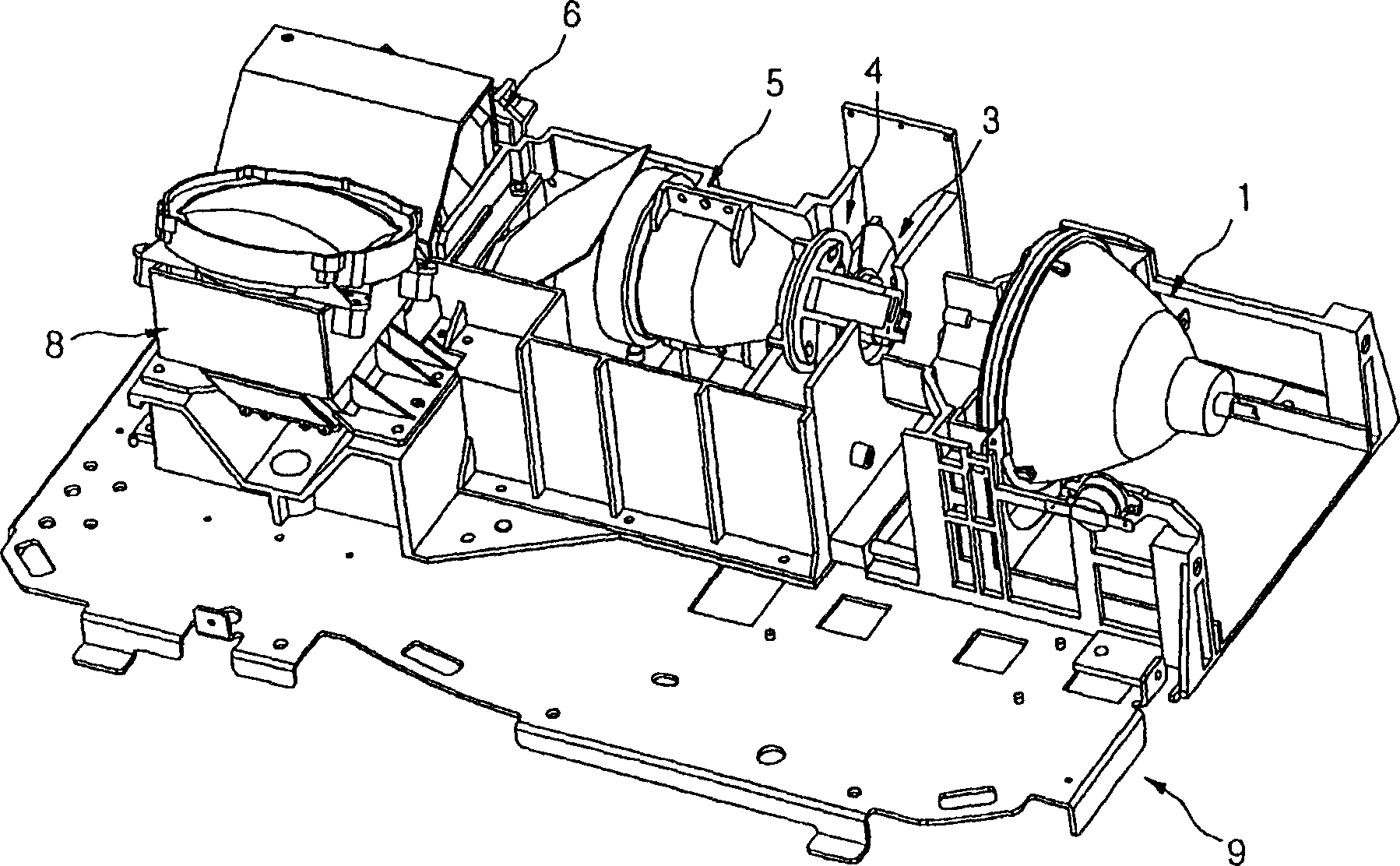

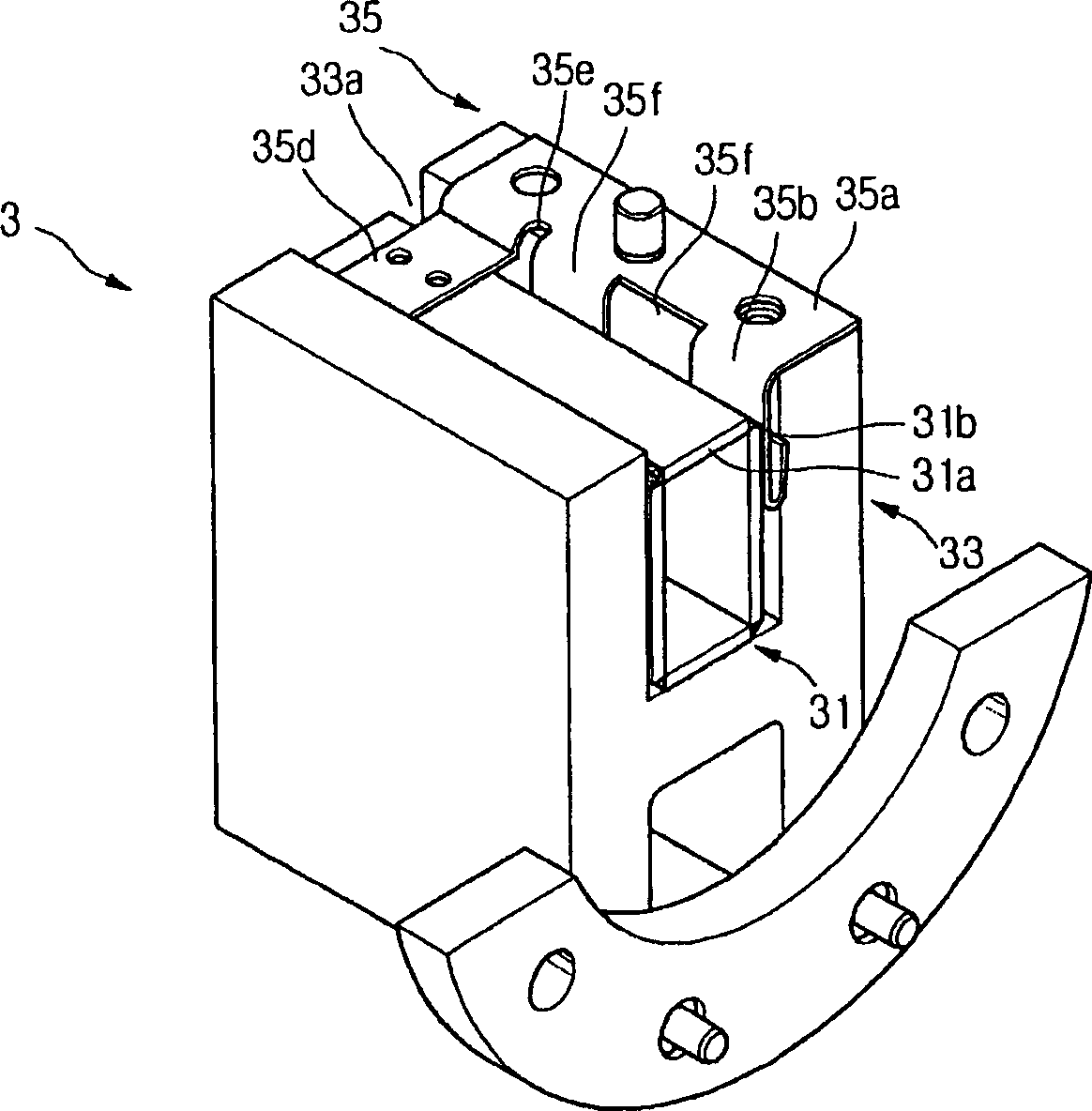

[0033] figure 1 is a structural diagram showing the structure of a DLP projection system according to the present invention, figure 2 is a perspective view of a light engine in a DLP projection system according to the present invention.

[0034] refer to figure 1 and 2 , the DLP projection system includes: a lamp 1 that generates light; a light tunnel portion 3 through which the light generated from the lamp 1 propagates; a color wheel 4 wherein the white light propagated through the light tunnel portion 3 is divided into RGB; a condenser lens 5, Concentrate the light passing through the color wheel 4; the prism 6, where the light passing through the condenser lens 5 is reflected; the DMD7, which focuses the light reflected on the prism 6 to the screen; and the projection lens 8, which amplifies the light reflected from the DMD7. In particular, the light tunnel 3 is formed so that the propagation of light generated from the lamp 1 has a uniform surface light source. Howev...

no. 2 example

[0057] Figure 5 is a lower perspective view in a detached state of the fixed slats in the light tunnel section according to the present invention, Image 6 is a lower perspective view in a state where the fixing strip is mounted on the light tunnel portion.

[0058] refer to Figure 5 and 6 , the light tunnel part of the DLP projection system according to the present embodiment includes: a light tunnel 130; a bracket 134, wherein the light tunnel is installed so as to be fixed to the light engine base; Light irradiated through other parts than the light tunnel 130 is shielded.

[0059] The light tunnel forms a reflective plate 132 in which a reflector having a reflective surface 132a is formed to reflect / refract the light projected in the light tunnel into a uniform surface light source. The size of the reflecting plate 132 forms a small shape with a length of 30mm, a width of 6.2mm, a height of 5.2mm and a thickness of 0.5mm.

[0060] The light tunnel 130 includes refle...

no. 3 example

[0069] The third embodiment of the present invention describes that the fixed slats included on the front of the light tunnel in the second embodiment can be included on the rear of the light tunnel, and the heat of the light tunnel in this embodiment is rapidly absorbed by the fixed slats. Radiates forward and backward from the light tunnel.

[0070] Figure 8 is a lower perspective view of a light tunnel according to a third embodiment, and Figure 9 Yes Figure 8 The cross-sectional view of the line I-I' in.

[0071] refer to Figure 8 and 9 , the light tunnel 130 reaches the arrival surface 136 of the bracket 134 , and the fixing strips 100 are respectively extended to the front and rear surfaces where light is irradiated and emitted to fix the light tunnel 130 to the bracket 134 . The fixing strip 100 is closely adhered to the front and rear surfaces of the bracket 134 in which the light tunnel 130 is installed so as to gently perform heat radiation and firmly suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com