Delivery device of electric components

A technology for conveying devices and electrical components, which is applied in the direction of electrical components, electrical components, etc., and can solve problems such as component jamming and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

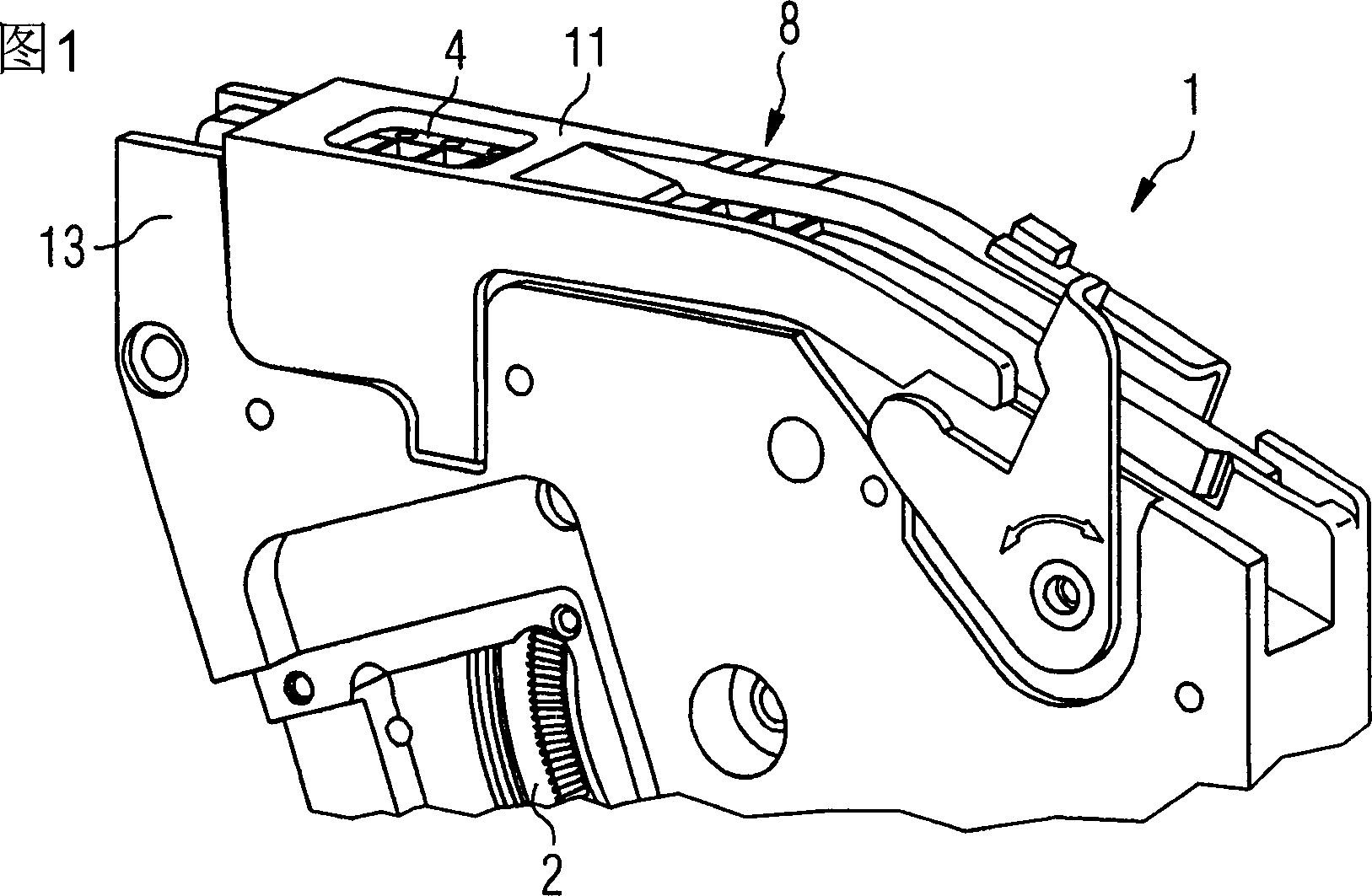

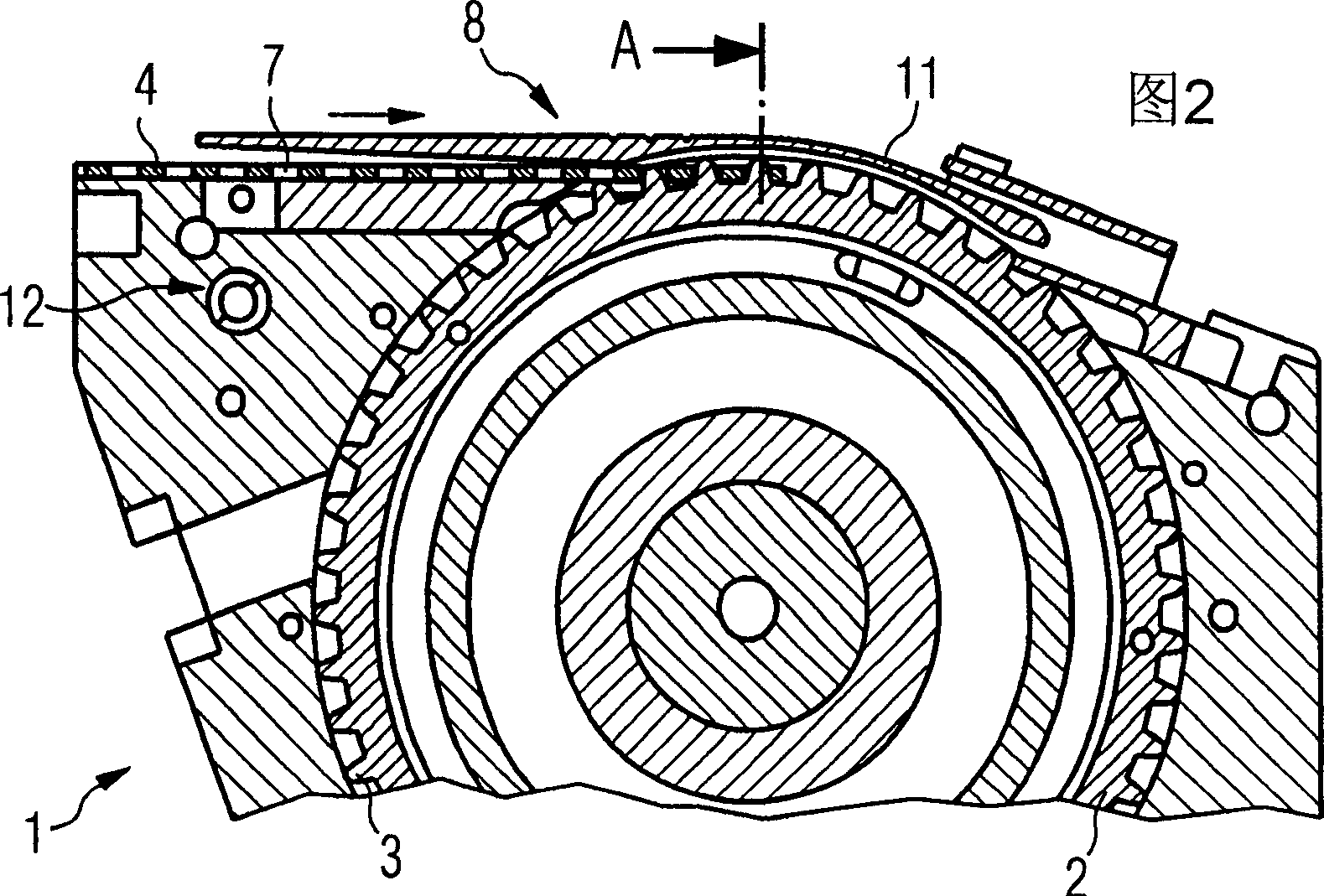

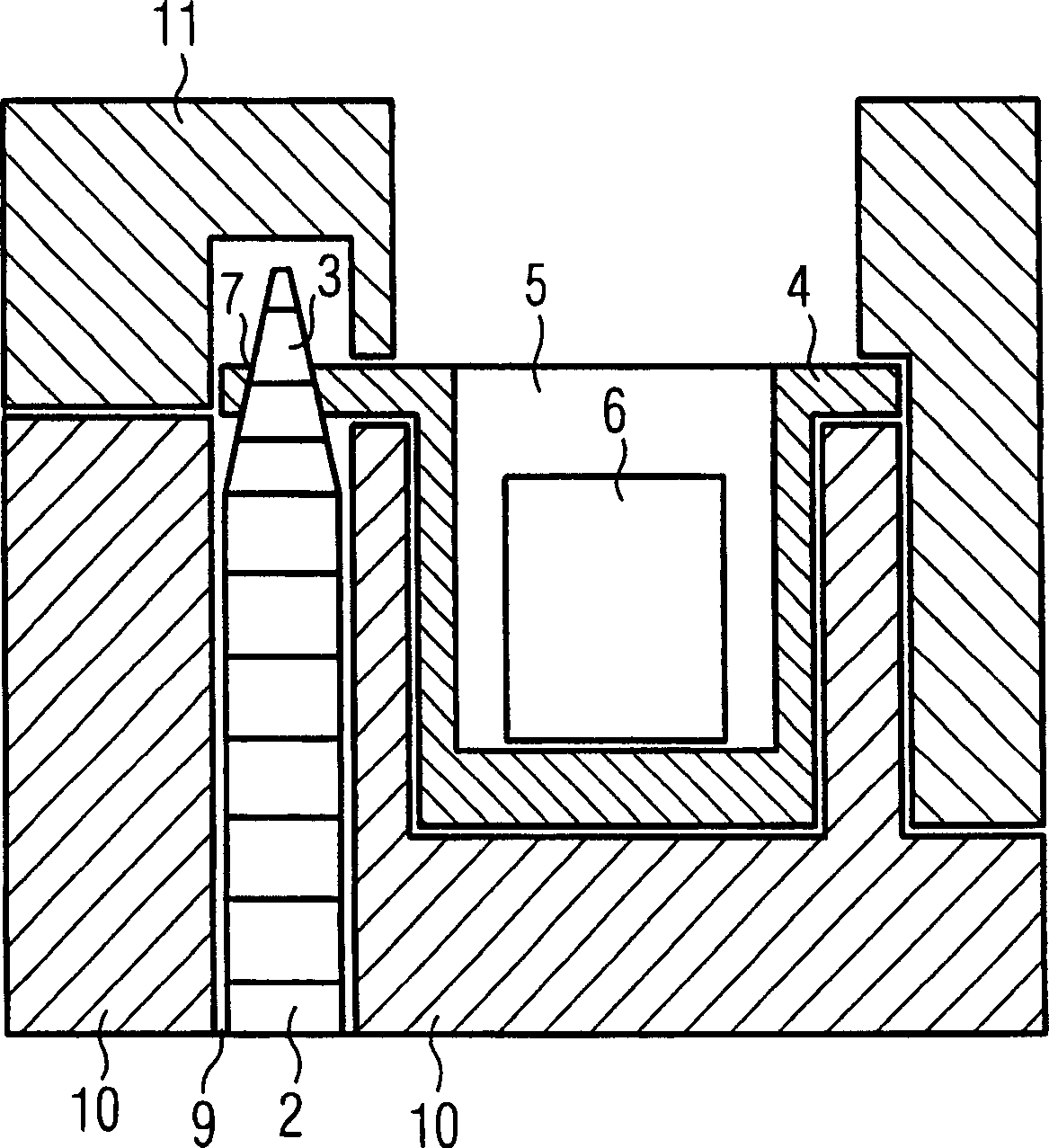

[0012] Figures 1 and 2 show perspective and cross-sectional views of an embodiment of a delivery device according to the invention. image 3 A schematic cross-section along section line A in FIG. 2 is shown. The conveying device 1 has a conveying wheel 2, on the outer circumference of which pins 3 extend radially. The component conveyor belt 4 , in which the electrical components 6 are accommodated in the pocket-like recess 5 , has laterally perforations 7 into which the pins 3 of the conveyor wheels 2 can engage. The components 6 are conveyed in the conveying direction (indicated by the arrow in FIG. 2 ) to the pick-up position 8 of the conveying device 1 by driving the conveying wheel 2 in rotation by means of a transmission not shown. At the pick-up position 8 , the electrical component 6 is picked up, for example, by a mounting head of an automatic assembly machine. In order to protect the components 6 , the component conveyor belt 4 usually has a protective film covering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com