Valve control device reducing noise

A valve control and controller technology, applied in engine control, charging system, internal combustion piston engine, etc., can solve problems such as increasing the trouble of car occupants

- Summary

- Abstract

- Description

- Claims

- Application Information

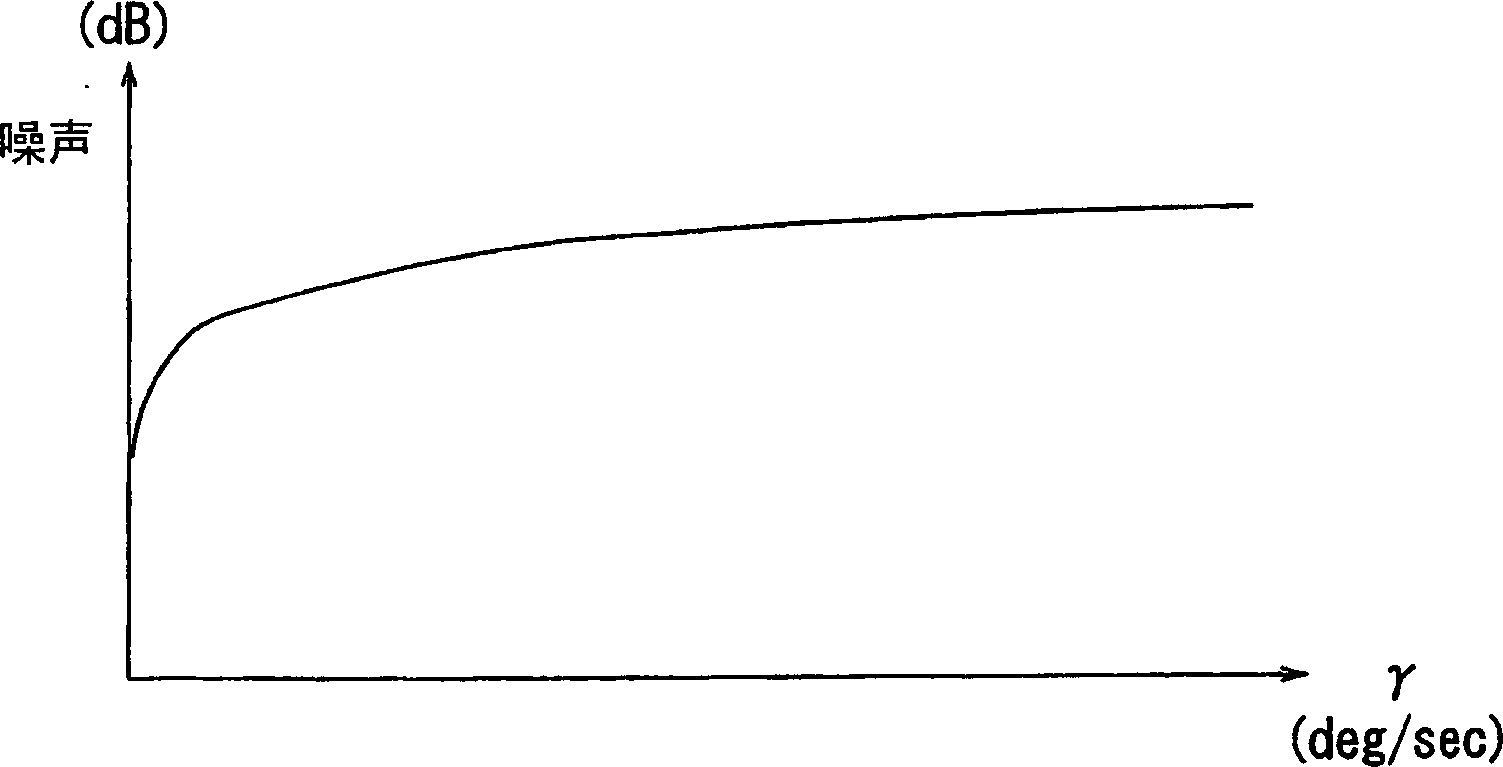

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

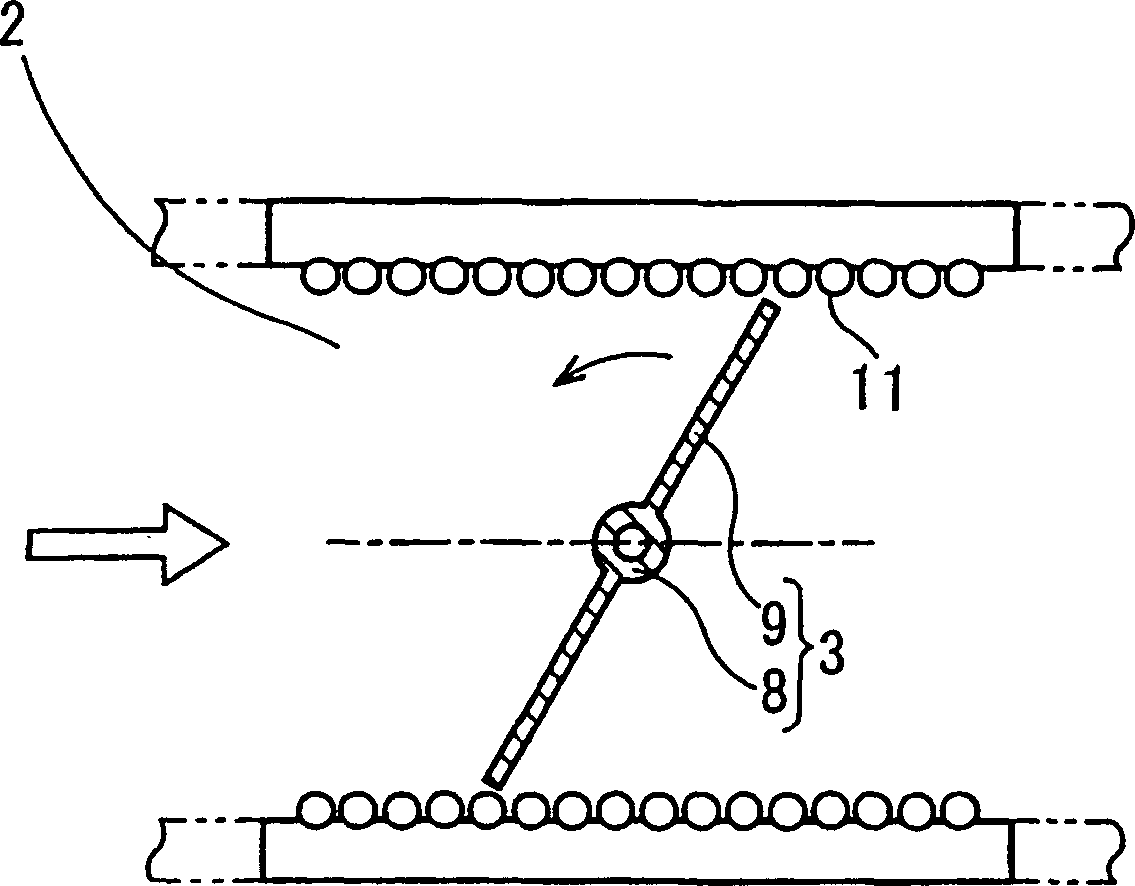

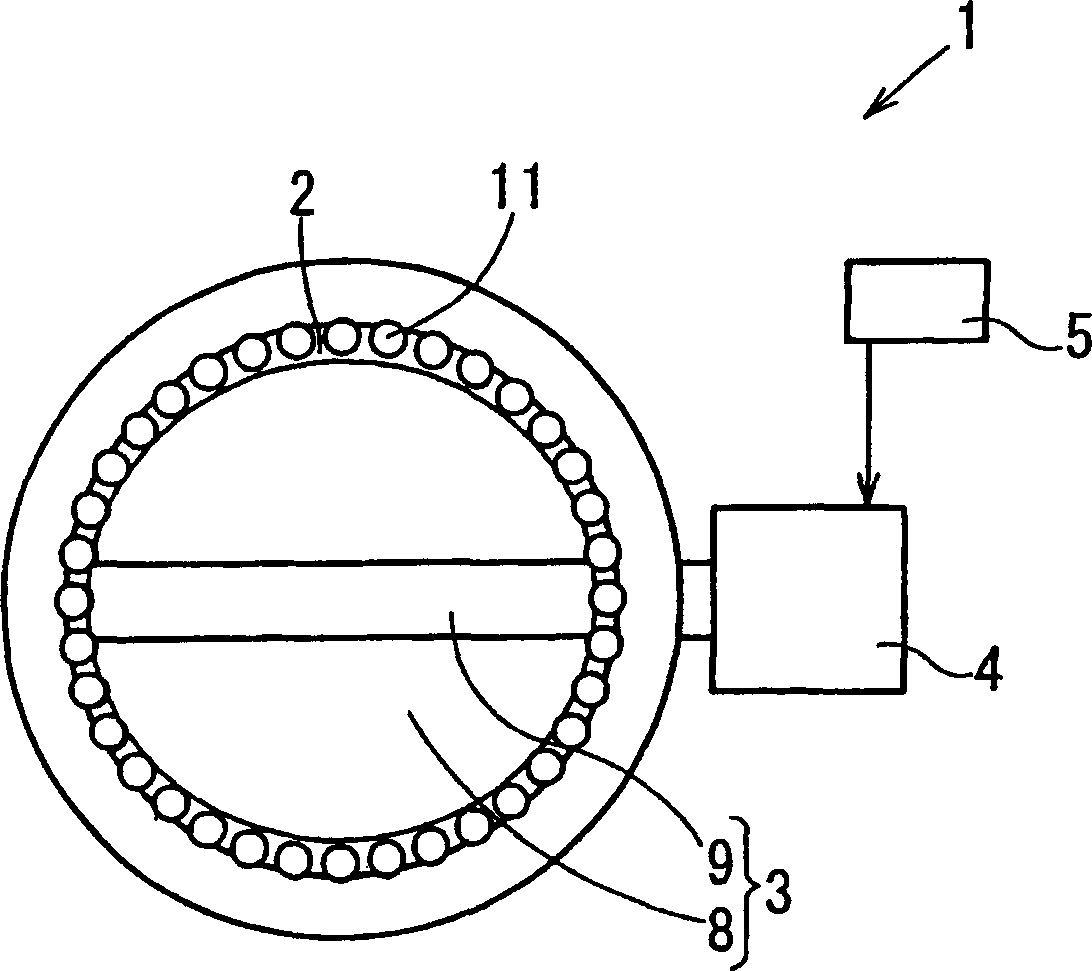

[0020] refer to Figure 1A and Figure 1B , shows a valve control device 1 according to a first embodiment of the invention, which drives and controls a valve 3, such as a throttle valve, an exhaust gas recirculation valve (EGR valve), or an exhaust gas restrictor valve. Through the valves, fluid enters and or discharges from the engine passages.

[0021] This valve arrangement 1 is inserted into a flow channel 2 which carries out the air supply and exhaust gas discharge of the engine. The valve control device 1 has a valve 3 , a motor 4 , and an electronic control unit (ECU) 5 . Valve 3 regulates the flow rate of intake or exhaust. The motor 4 is an actuator that drives the valve 3 . The ECU 5 functions as a controller to drive and control the valve 3 by controlling the operation of the motor 4 .

[0022] For example, the valve 3 is a disc valve having a shaft portion 8 connected to a rotation shaft (not shown) of the motor 4 and a substantially circular plate portion 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com