An induction conveying device and a conveyor

A technology of conveying device and conveying mechanism, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as affecting the working efficiency of the crusher, uneven feeding, etc., achieving simple structure, slowing down work efficiency, and increasing The effect of drive speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

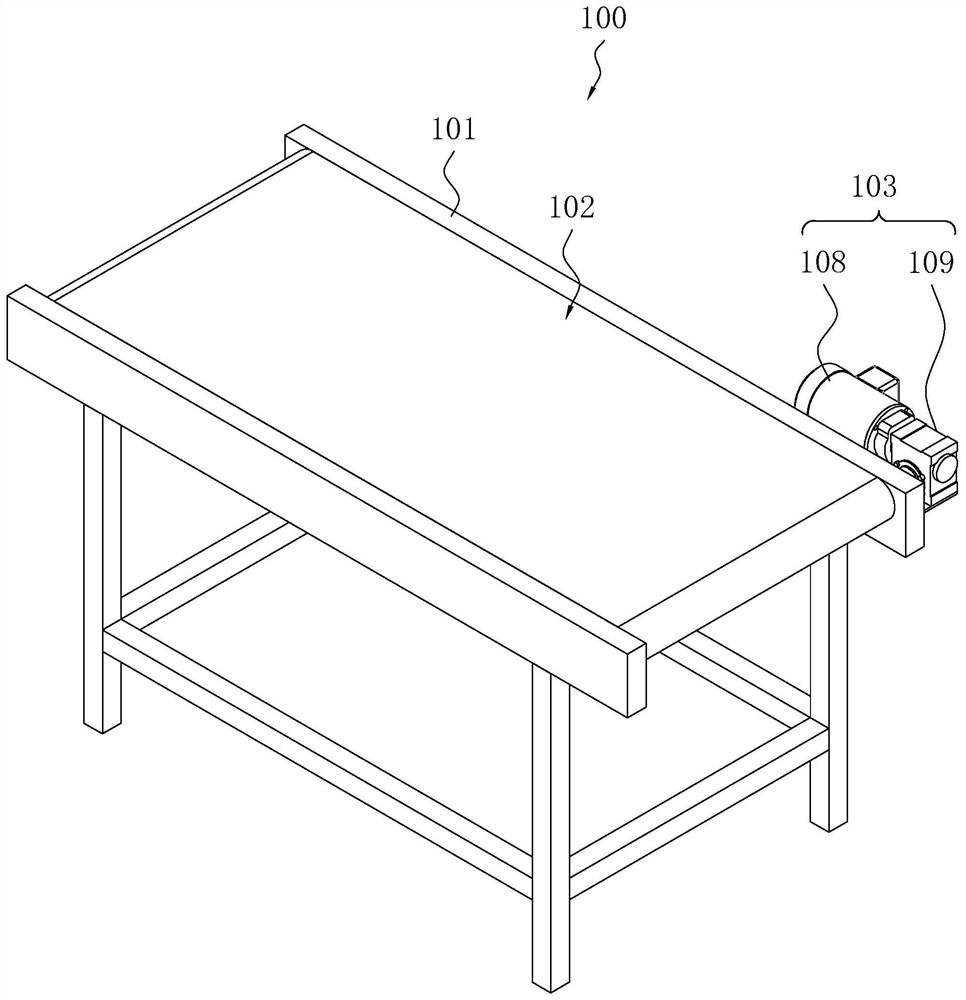

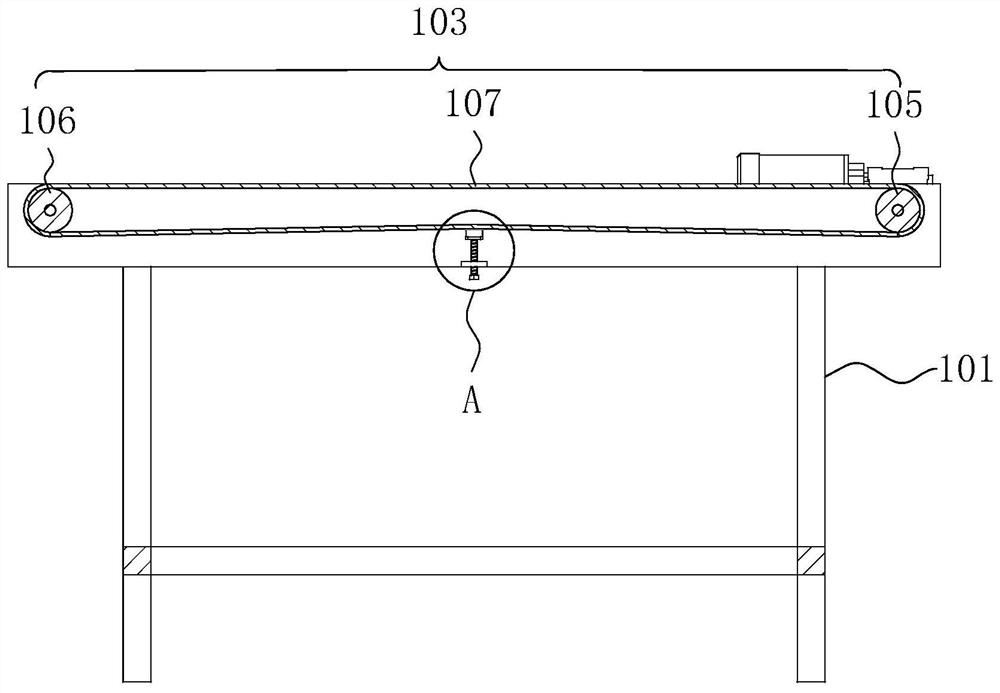

[0044] refer to figure 1 , an induction conveying device 100 includes a frame 101, which is connected with a conveying mechanism 102, a driving mechanism 103 and a detecting mechanism. The conveying mechanism 102 is used for conveying materials horizontally or obliquely. The driving mechanism 103 is connected with the conveying mechanism 102 and provides power for the conveying mechanism 102 . The detection mechanism is used to detect the weight of the material conveyed on the conveying mechanism 102, and control the driving speed of the driving mechanism 103 so that the driving speed of the driving mechanism 103 slows down as the weight of the conveyed material on the conveying mechanism 102 increases.

[0045] refer to figure 1 , the detection mechanism detects the weight of the material conveyed on the conveying mechanism 102, judges the amount of material on the conveying mechanism 102 by the weight of the material, and then controls the driving speed of the driving mech...

Embodiment 2

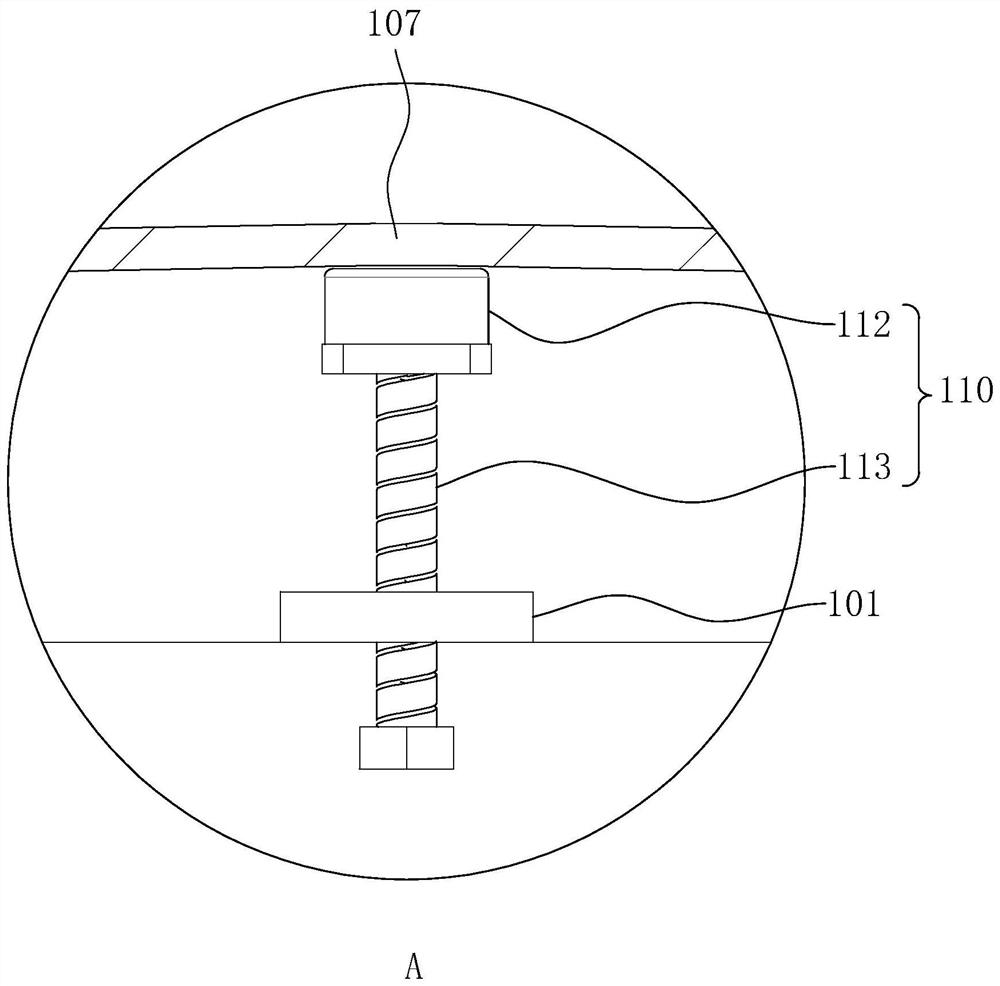

[0052] refer to Figure 4 , an inductive conveying device 100 , which differs from Embodiment 1 in that a load detection component 110 is present.

[0053] refer to Figure 4 , the load detection component 110 includes a DC drive motor 114 and a current sensor for detecting the current intensity of the DC drive motor 114 . The DC drive motor 114 is fixedly connected to the frame 101 and its main shaft is coaxially fixedly connected to the end of the driving roller 105 away from the servo motor 109 .

[0054] The PLC controller is electrically connected with a timer. After every X seconds, the PLC controller 111 controls the servo motor 109 to stop working and controls the DC drive motor 114 to work for Y seconds, and utilizes the current sensor to detect the current of the DC drive motor 114 when it is working, thereby Judging the weight of the material on the conveying mechanism 102, then controlling the servo motor 109 to continue working for X seconds, as before, without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com