Spiral bellows type heat exchanger

A technology of spiral bellows and heat exchangers, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of inconvenient installation and maintenance, difficult processing technology, high thermal efficiency, etc., and achieve convenient installation and maintenance, and use The effect of long life and small water pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

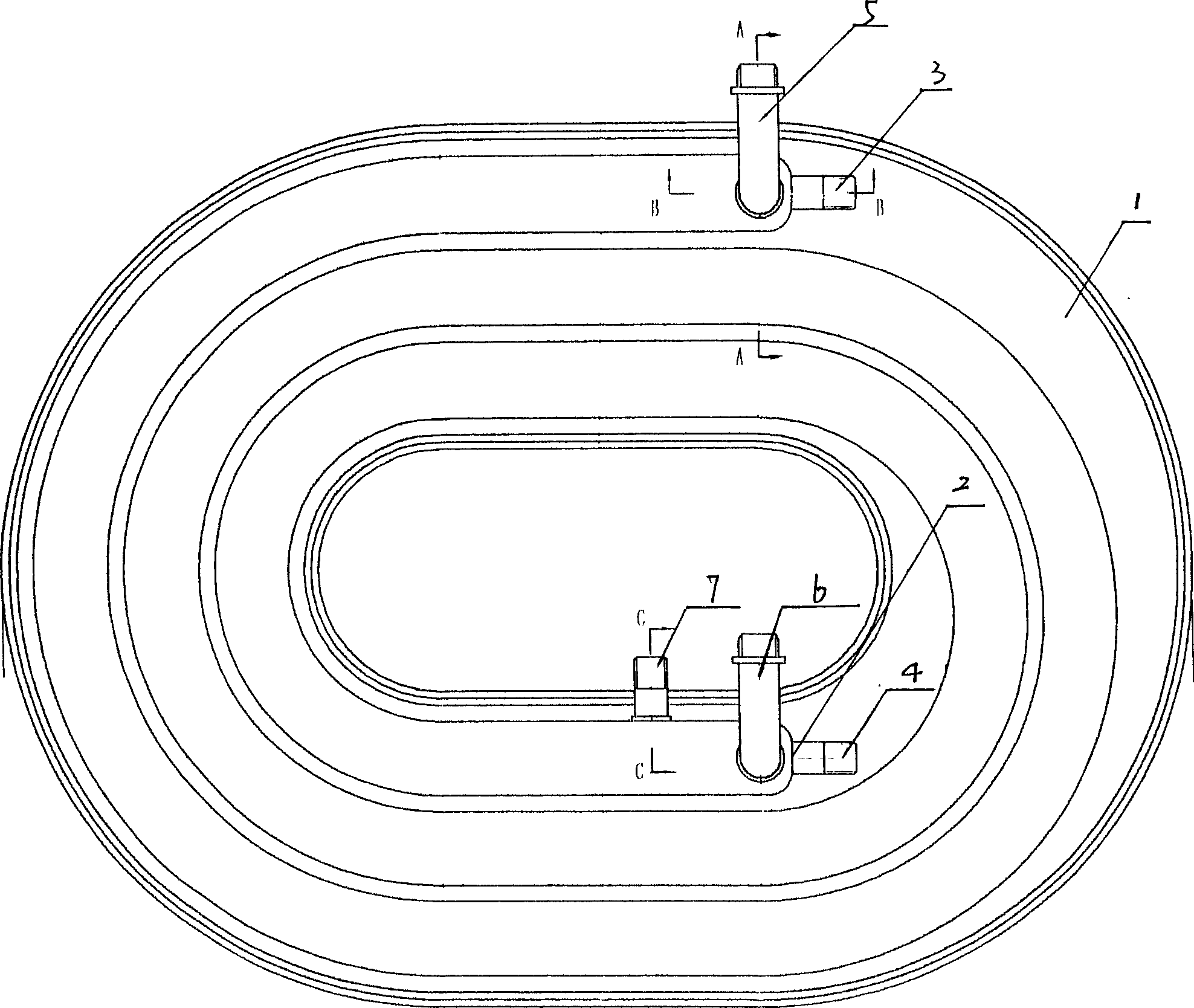

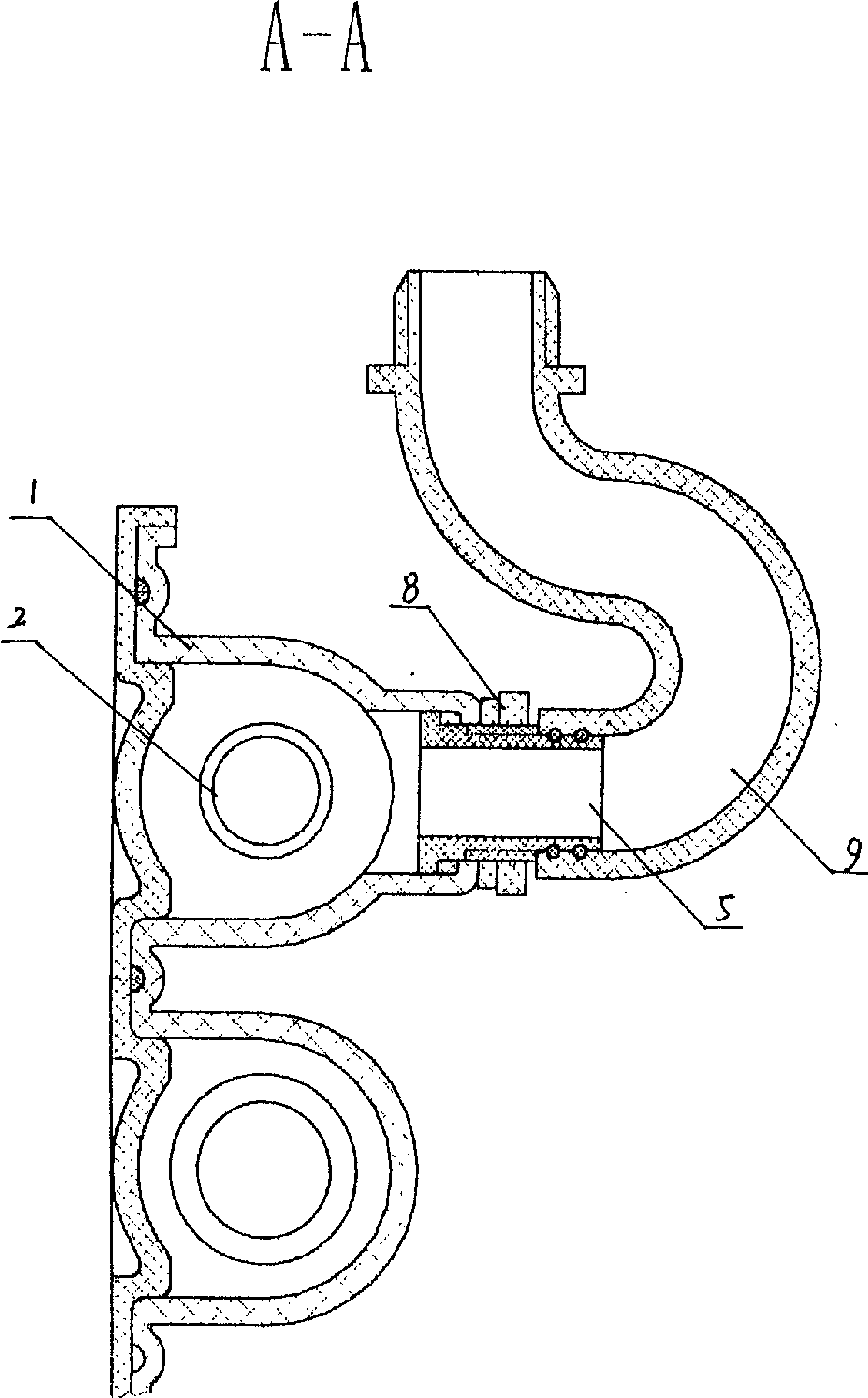

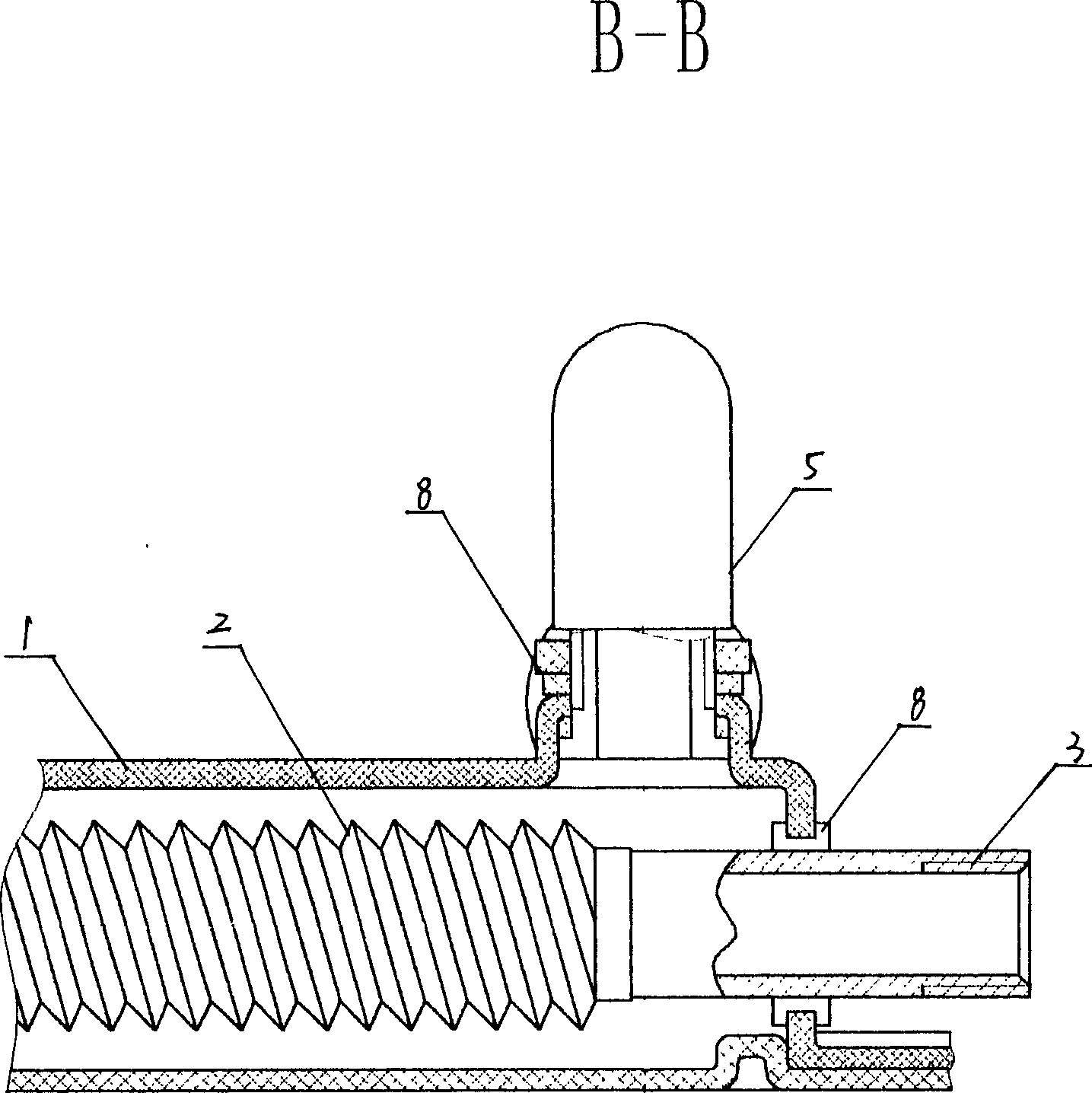

[0012] Such as figure 1 , 2 , 3, the heat exchanger is mainly composed of a jacket 1 and a bellows 2. The bellows 2 are arranged spirally and annularly in the jacket 1 to form the main body of the heat exchanger as a whole. The two ends of the bellows 2 are installed with clean water through the connector 8. Water inlet and outlet 3,4, waste water inlet and outlet 5,6 are installed through connector 8 on the overcoat 1.

[0013] The inside of the bellows 2 is clean tap water, and the channel formed by the outer wall of the bellows 2 and the inner wall of the jacket 1 is waste hot water with poor cleanliness, and the two media form convection to fully exchange heat. When the low-temperature tap water flows from the water inlet 3 to the water outlet 4 at the other end through the bellows 2, the high-temperature waste water flows from the waste water inlet 6 to the waste water outlet 5 at the other end through the channel formed by the outer wall of the bellows 2 and the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com