Welding work field coordinated management system based on CAN bus

A CAN bus, collaborative management technology, applied in welding equipment, arc welding equipment, comprehensive factory control, etc., can solve the problems of strong interference, can not work normally, simulation collaborative application is not ideal, etc., to achieve strong anti-interference ability and stability Improved performance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

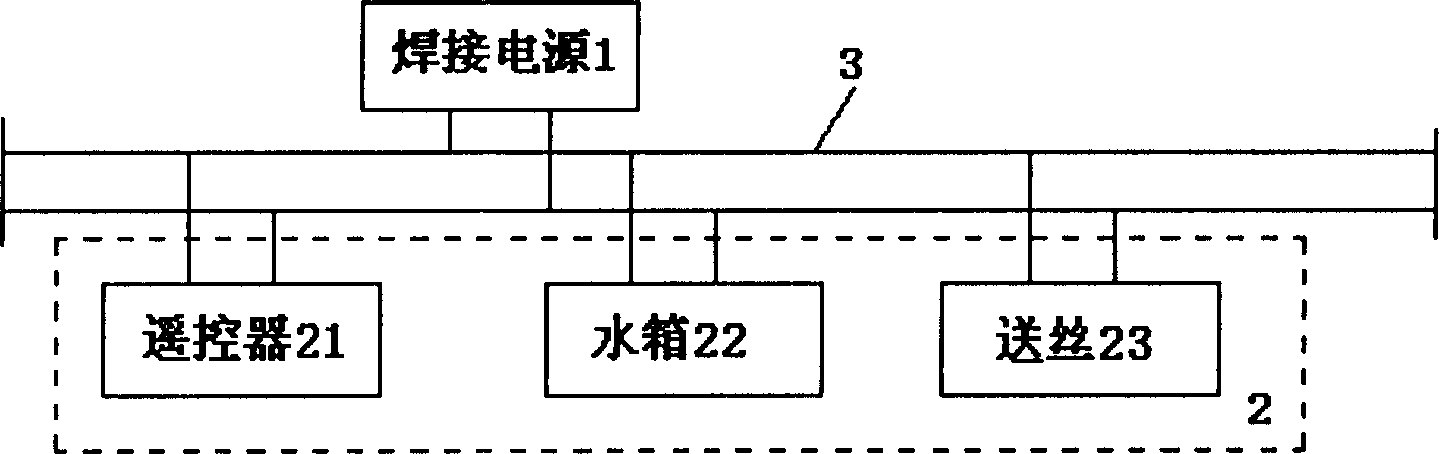

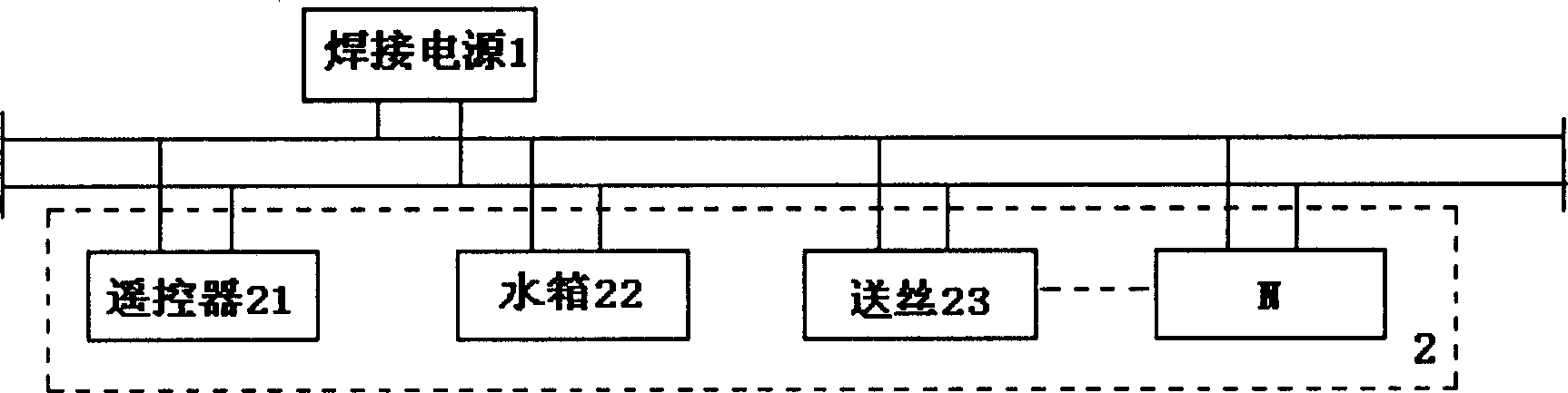

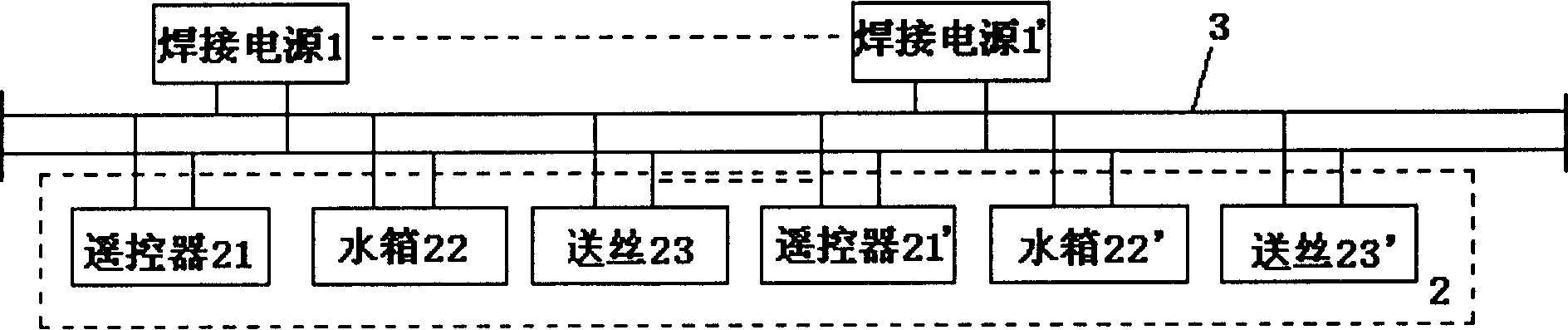

[0023] Such as figure 1 As shown, the CAN bus-based welding site collaborative management system of the present invention includes: a welding power supply control unit 1, which is used to provide the current required for welding; an external cooperative execution unit 2, which includes a water tank unit 22 and a wire feeding unit 23. The water tank unit 22 adjusts the speed of providing cooling water to the welding torch according to the current provided by the welding power supply, and the wire feeding unit 23 adjusts the wire feeding speed of the wire feeder according to the current provided by the welding power supply; the welding power supply control unit 1 cooperates with the external Each unit of unit 2 is an embedded control unit with a CAN bus controller; the control area CAN bus 3, the welding power supply control system 1 and the external cooperative execution unit 2 realize mutual communication by connecting to the CAN bus 3 .

[0024] The welding system mainly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com