Magnetic block mounting holding device on hard disk

A technology for installing fixtures and magnetic blocks, which is applied in the direction of magnetic recording, instruments, record carrier structural parts, etc., can solve problems such as fatigue, easy-to-bruise precision parts, and limited space, so as to reduce fatigue, improve production efficiency, and install accurately smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

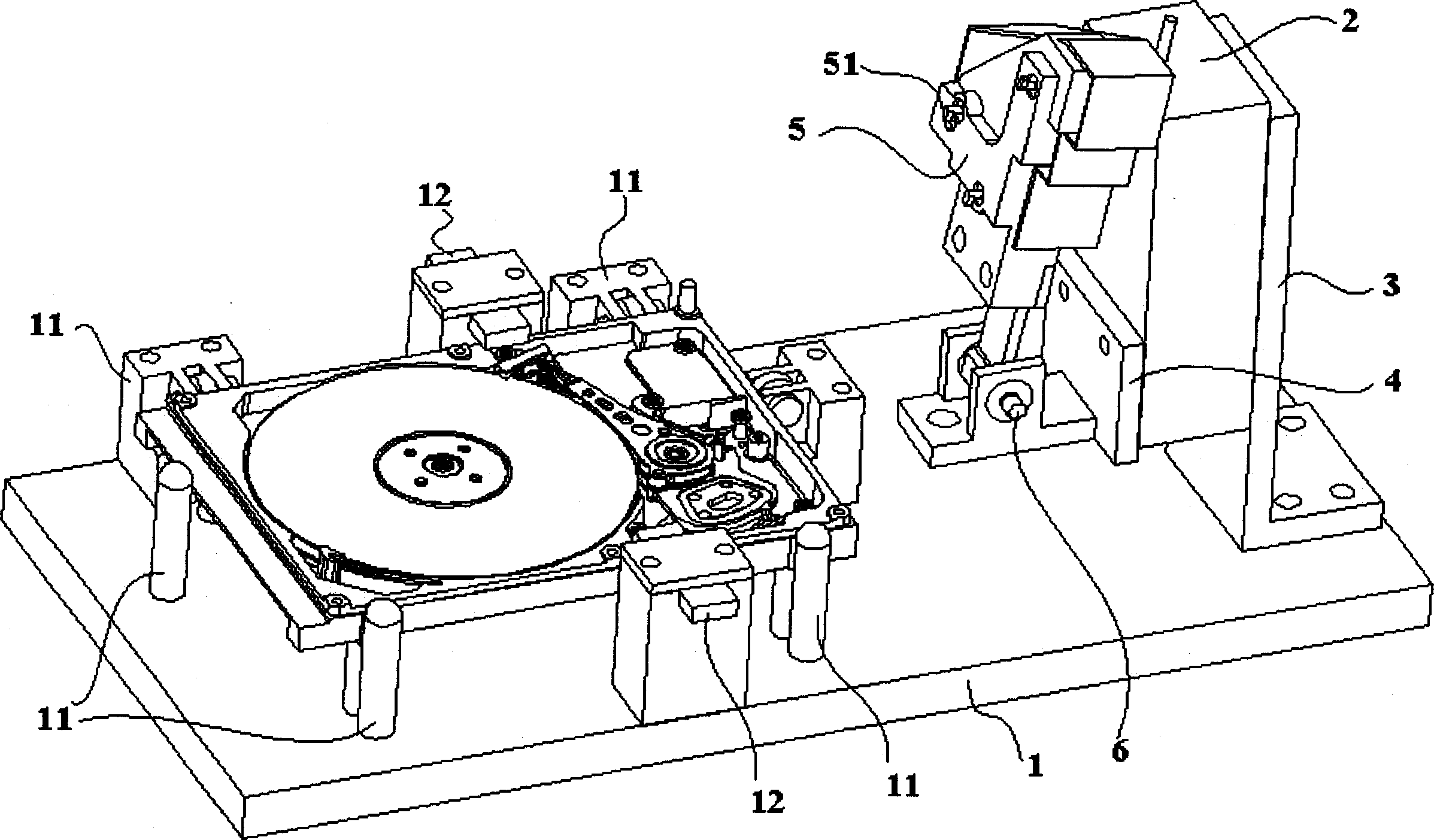

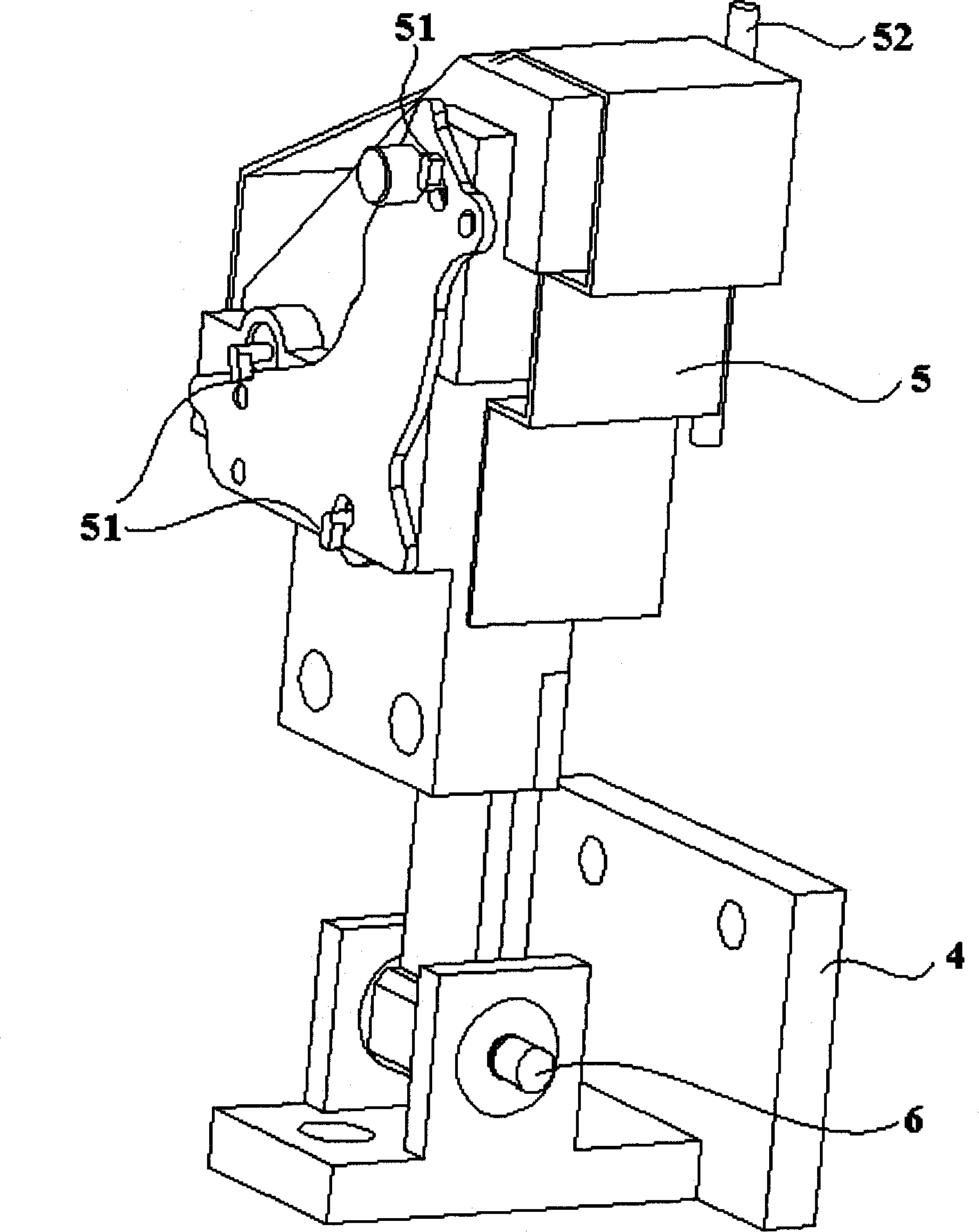

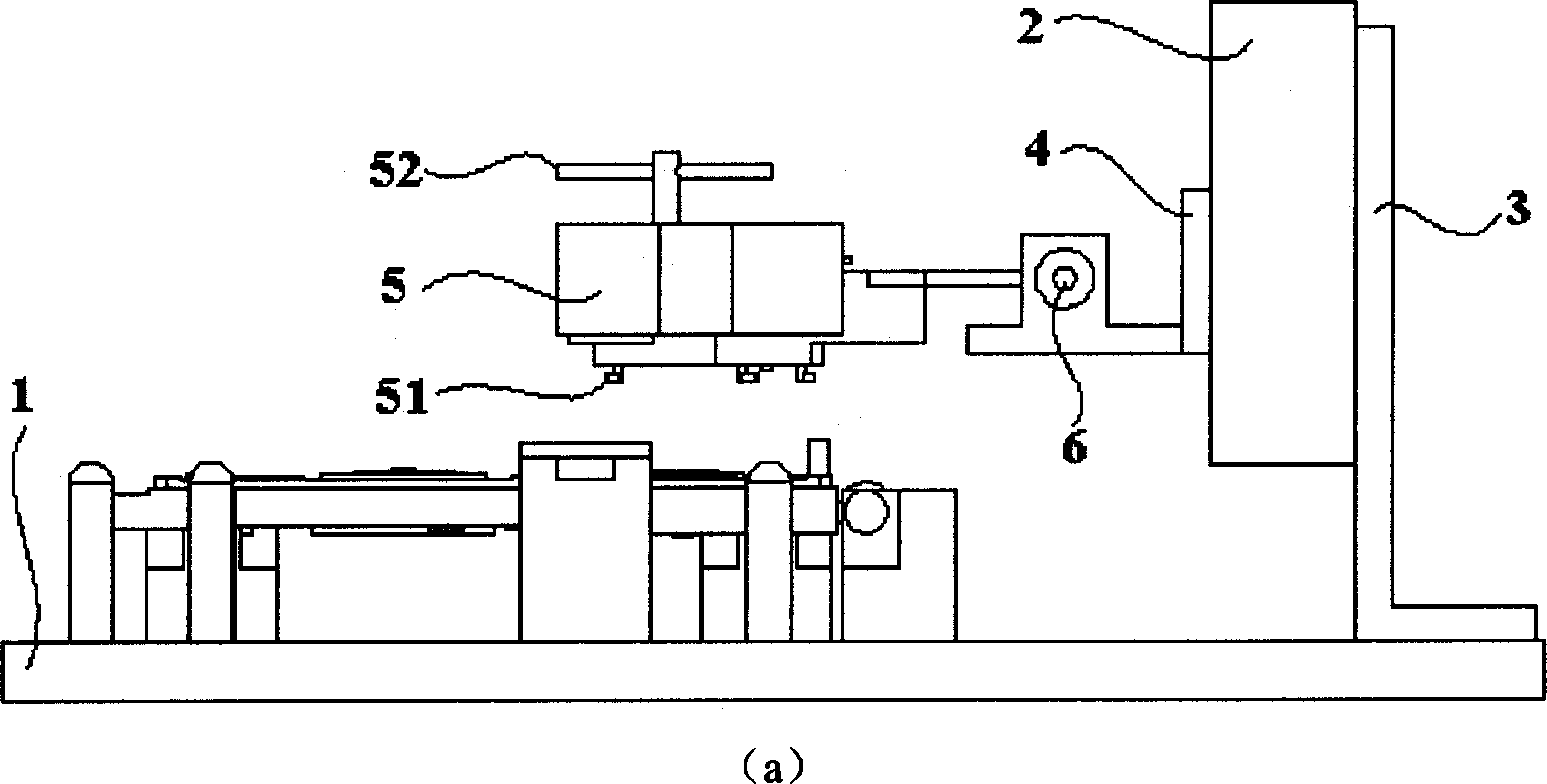

[0016] An upper magnetic block mounting fixture, such as figure 1 and figure 2 As shown, it includes a mounting table 1 for fixing a hard disk, a lifting cylinder 2 and an upper magnetic block clamping mechanism. The clamping mechanism for the upper magnetic block includes a guide rail 3, a slider 4 and a pallet 5 for horizontally clamping the upper magnetic block. The guide rail 3 is vertically fixed on the installation platform 1; the slider 4 moves up and down along the guide rail 3 driven by the lifting cylinder 2; the support platform 5 is connected with the slider 4 through the rotating shaft 6, and can be turned from a horizontal position to a position parallel to the guide rail 3 vertical position.

[0017] The pallet 5 is provided with a cylindrical positioning pin 51 and a driving lever 52; the positioning pin 51 is rotatable and arranged perpendicular to the surface of the pallet 5, and its top is bent in an "L" shape; the driving rod 52 is connected with the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com