Fault-preventing device of engine

A fail-safe and engine technology, applied in the direction of lubrication indicator device, pressure lubrication safety device, lubrication parts, etc., can solve the problems of scrapped body, complex structure, high manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

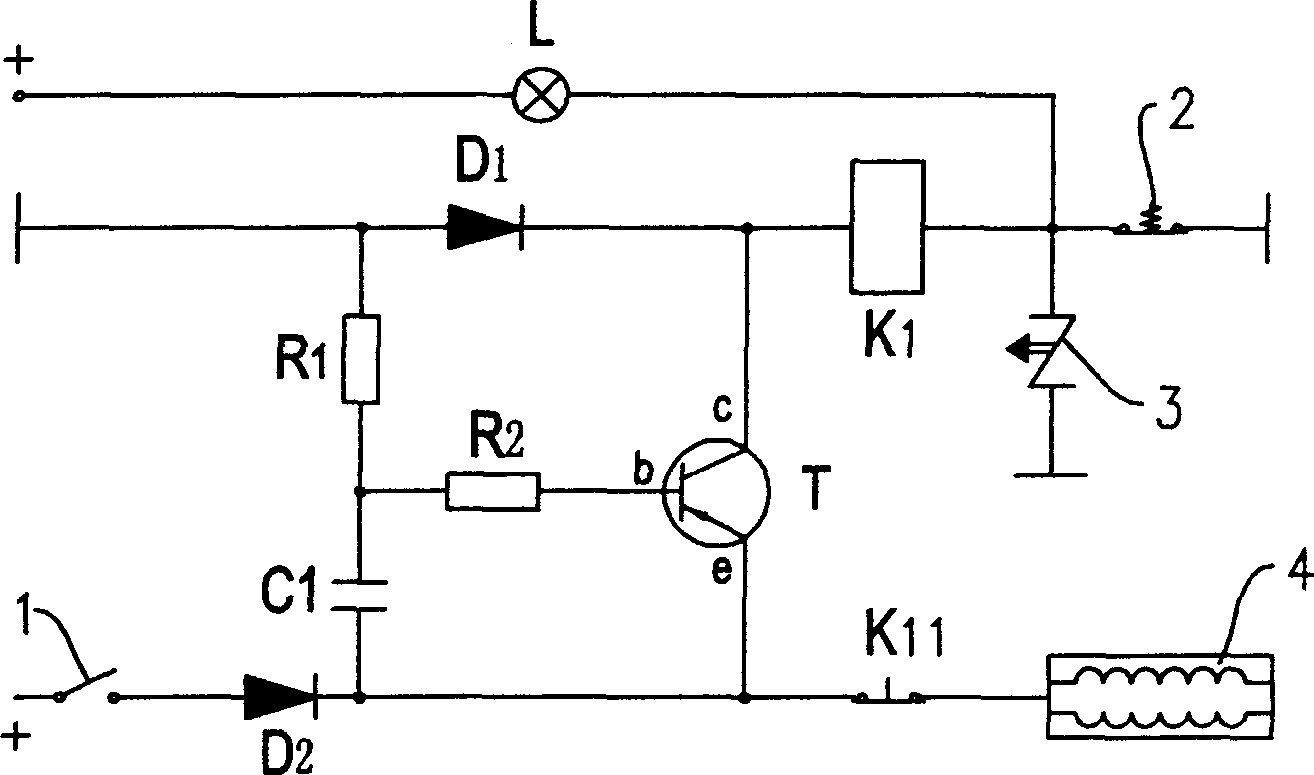

[0018] The first embodiment: as figure 1 As shown, the engine failure protection device includes an ignition coil control circuit electrically connected to the ignition switch 1, and an engine failure detection circuit; the ignition coil control circuit is connected in parallel with the engine failure detection circuit; the ignition coil control circuit includes The ignition coil 4, the engine failure detection circuit includes an engine oil pressure switch 2, and a thermal switch 3, and the engine oil pressure switch 2 and the thermal switch 3 are connected in parallel. When the oil pressure is lower than the set value, the oil pressure switch 2 is closed, and when the oil pressure is higher than the set value, the oil pressure switch 2 is disconnected. When the temperature of the coolant is higher than the set value, the thermosensitive switch 3 is closed, and when the temperature of the coolant is lower than the set value, the thermosensitive switch 3 is disconnected. The ...

Embodiment approach

[0024] This embodiment is suitable for gasoline vehicles.

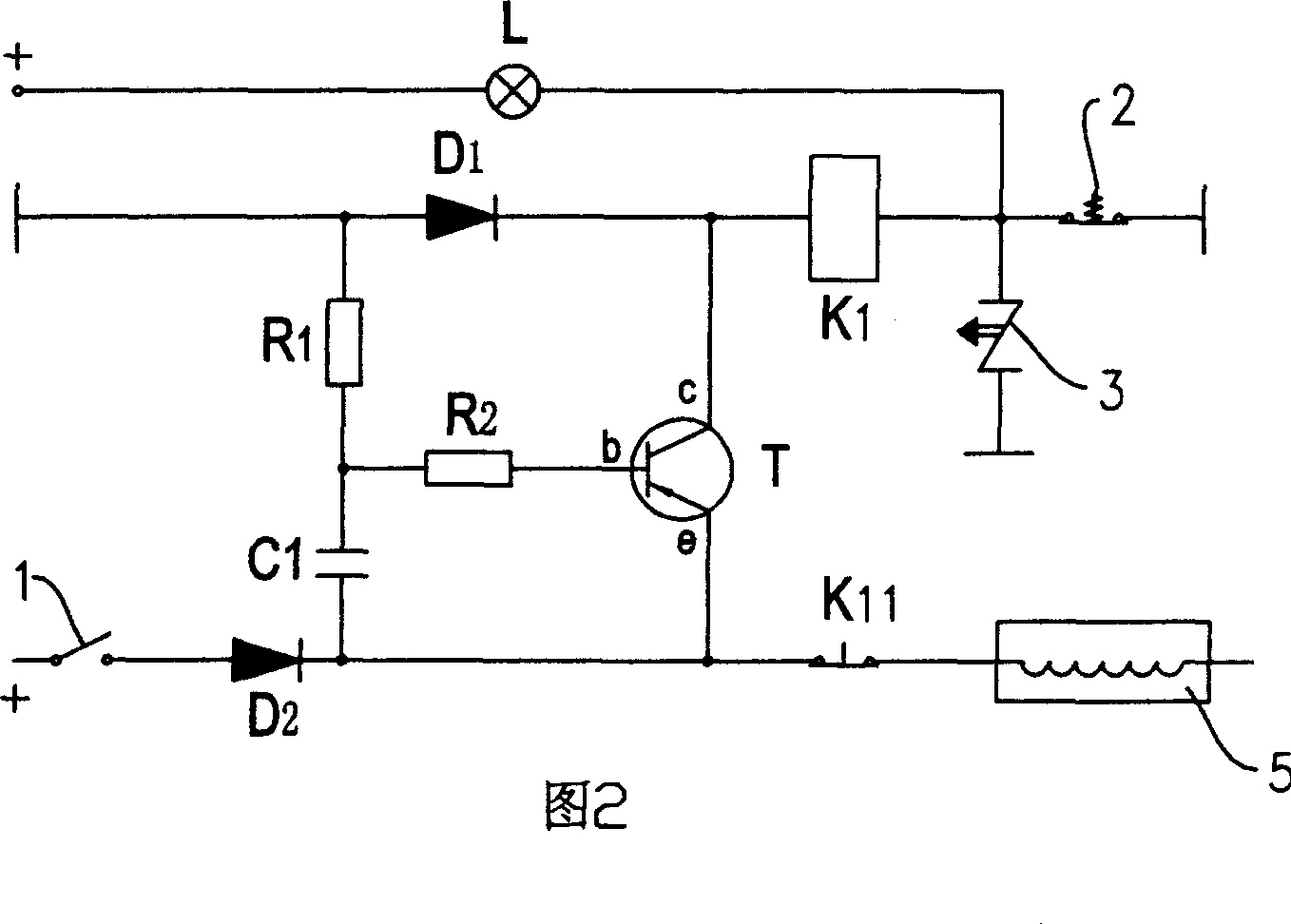

[0025] The second is the embodiment: as shown in Figure 2, its structure is basically the same as that of the first embodiment, the difference is that the ignition coil control circuit is replaced by the fuel stop solenoid valve control circuit, and the fuel stop solenoid valve control circuit includes a fuel stop Solenoid valve 5. This embodiment is suitable for diesel vehicles.

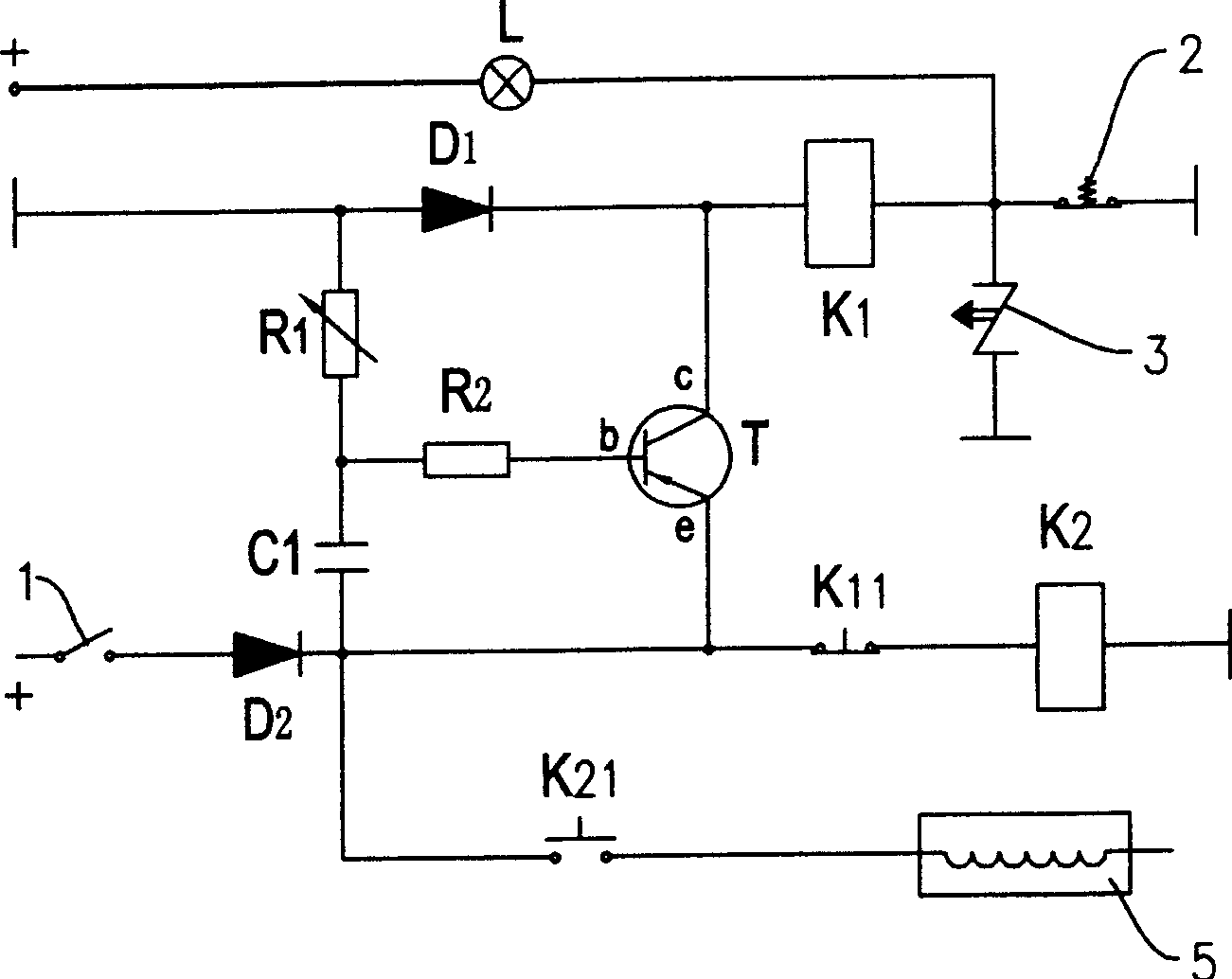

[0026] The third is the embodiment: such as image 3 As shown, its structure is basically the same as the second embodiment, and is also suitable for diesel vehicles. Since some fuel stop solenoid valves 5 need to be driven by a large current, this embodiment is designed for adapting to the fuel stop solenoid valve driven by a large current.

[0027] The difference is that the oil stop solenoid valve control circuit includes a high-current relay branch, the high-current relay branch includes a high-current relay K2, and the normally clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com