Anticounterfeit seal, and its manufacturing method and complete detecting film

A manufacturing method and technology for seals, applied in the field of anti-counterfeiting seals and inspection films, can solve the problems of few seal features, high technical requirements, uneven images, etc., and achieve the effect of simple implementation, low technical requirements, and anti-counterfeiting effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The manufacture method of anti-counterfeit seal of the present invention comprises the steps:

[0052] step one

[0053] Generate a dot matrix image according to the preset anti-counterfeiting image;

[0054] A) The background image is generated by extracting fixed points or drawing grid lines to generate a bitmap of the background image;

[0055] B) generate the anti-counterfeit image bitmap in the same way as step A;

[0056] C) the anti-counterfeit image bitmap generated in step B is dislocated relative to the background image bitmap generated in step A and covered on the background image bitmap generated in step A to form a bitmap, anti-counterfeit image bitmap The dislocation with the bitmap of the background image is generated by moving the bitmap of the anti-counterfeiting image relative to the bitmap of the background image by a certain distance, and the moving distance is smaller than the center distance between two points in the bitmap of the background image....

Embodiment 2

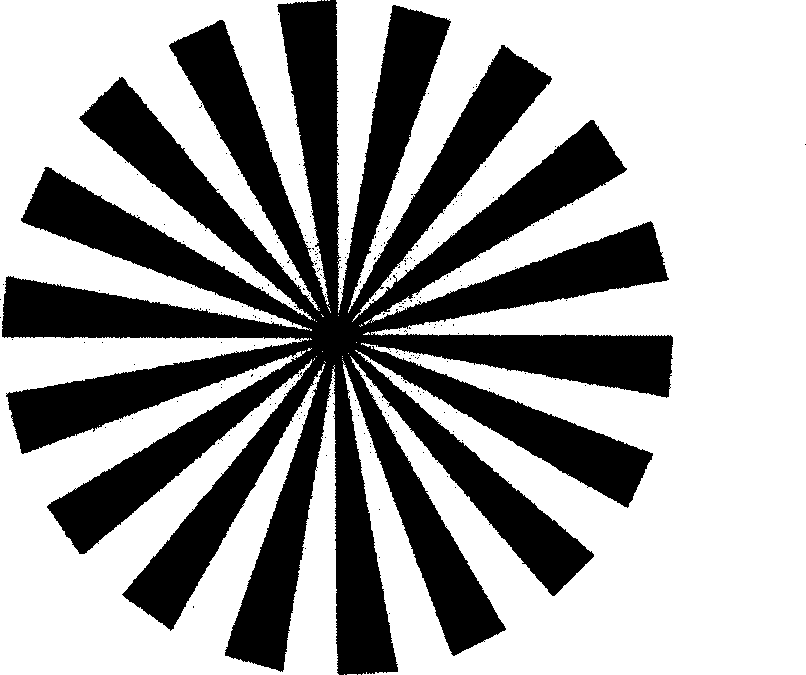

[0062] Combine below Figure 1 to Figure 18 , further illustrate the manufacture method of anti-counterfeit seal of the present invention.

[0063] Step 1: Generate bitmap

[0064] The following two anti-counterfeit images are taken as examples to illustrate the generation principle and display principle of the bitmap:

[0065] The bitmap is composed of the background bitmap, the first anti-counterfeiting image bitmap and the second anti-counterfeiting image bitmap. Its specific generation steps are as follows:

[0066] A) Generate background image bitmap:

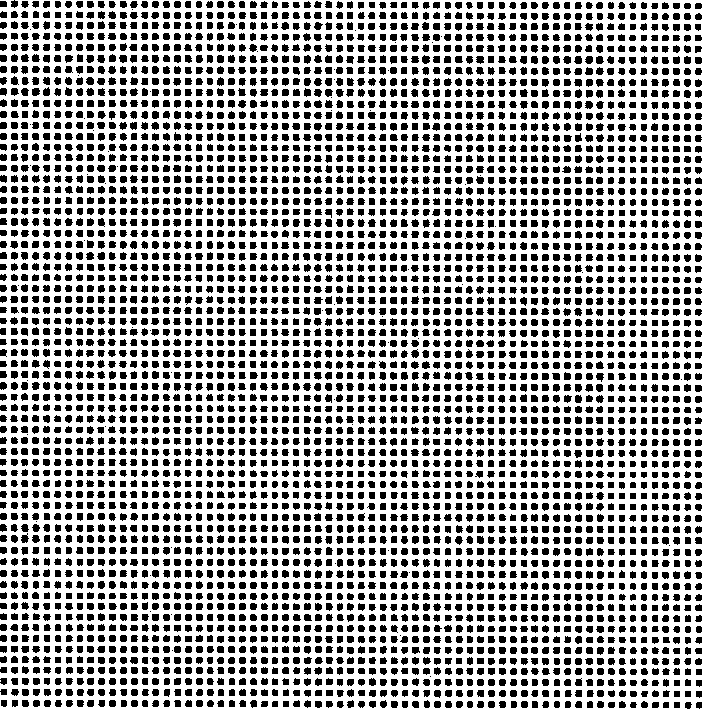

[0067] The background image uses a solid color pattern, black in this example, such as figure 1 As shown, the background image bitmap is obtained by extracting fixed points from the upper left or drawing white grid lines, as shown in figure 2 As shown, if a fixed point is extracted, the point width of the extracted fixed point is 0.05mm. Of course, a larger or smaller point can also be used. In this embodiment, the p...

Embodiment 3

[0082] The difference between the present embodiment and the second embodiment is that the step of generating the bitmap in step 1 is as follows:

[0083] A) generate a background image bitmap;

[0084] B) generating the first anti-counterfeit image bitmap;

[0085] C) generate the second anti-counterfeit image bitmap;

[0086] D) Move the first bitmap of the anti-counterfeiting image to the left or right for a certain distance relative to the bitmap of the background image and cover it on the bitmap of the background image; The bitmap is moved to the left or right by a certain distance and overlaid on the background image bitmap to generate a bitmap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com