Method and apparatus for aligning magnetizable particles in a pasty material

A paste-like, particle-based technology, applied in the field of devices and methods for orienting magnetizable particles in paste-like materials, capable of solving problems such as release reduction layer structure quality, not optimal fiber orientation, irregular orientation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

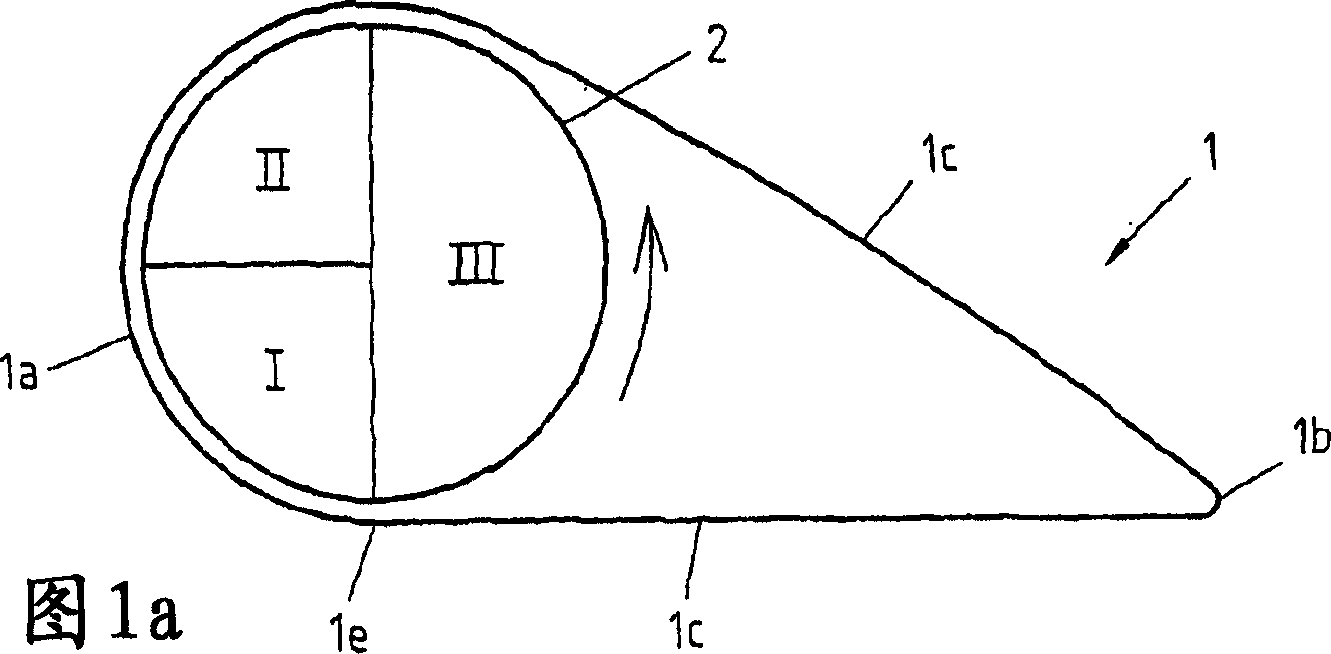

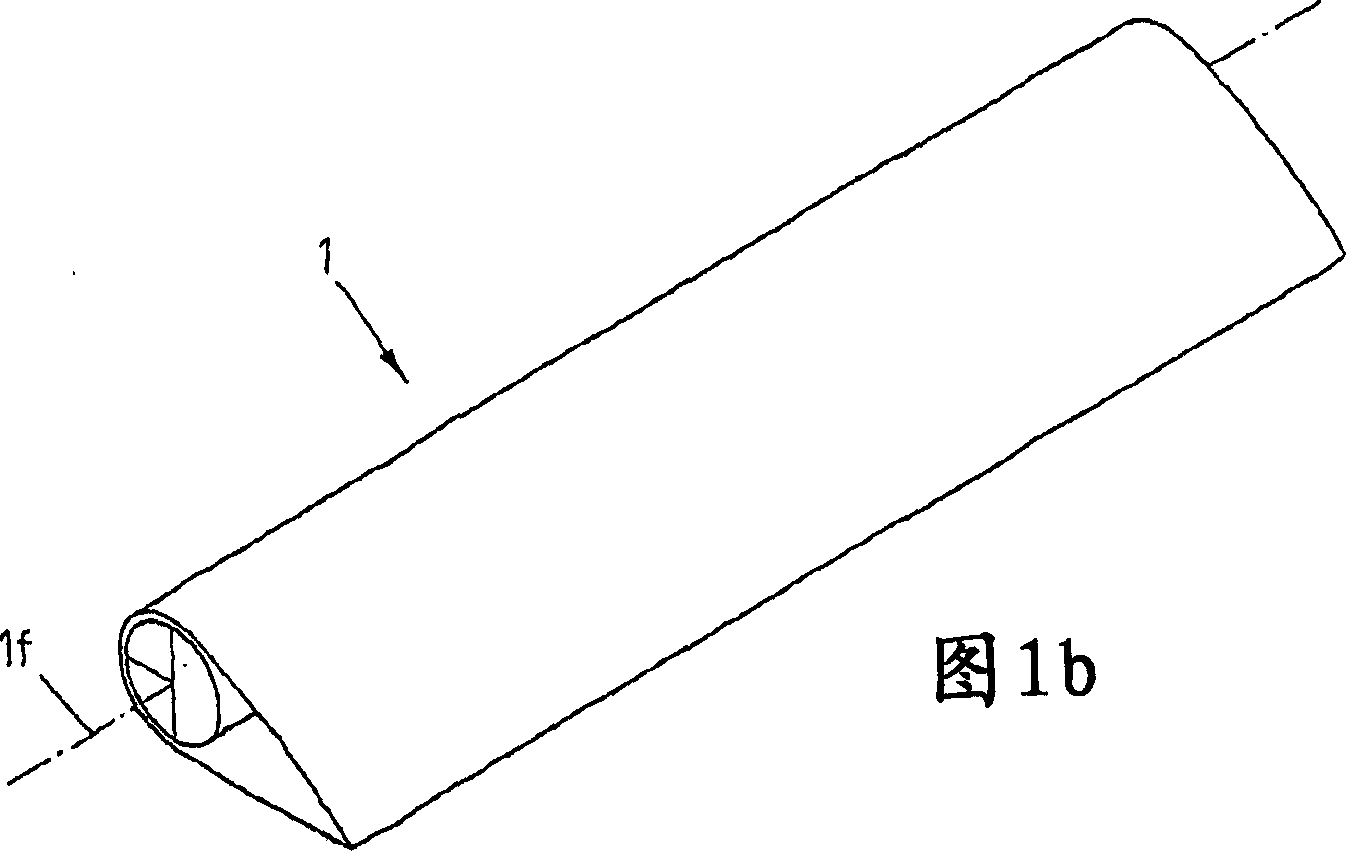

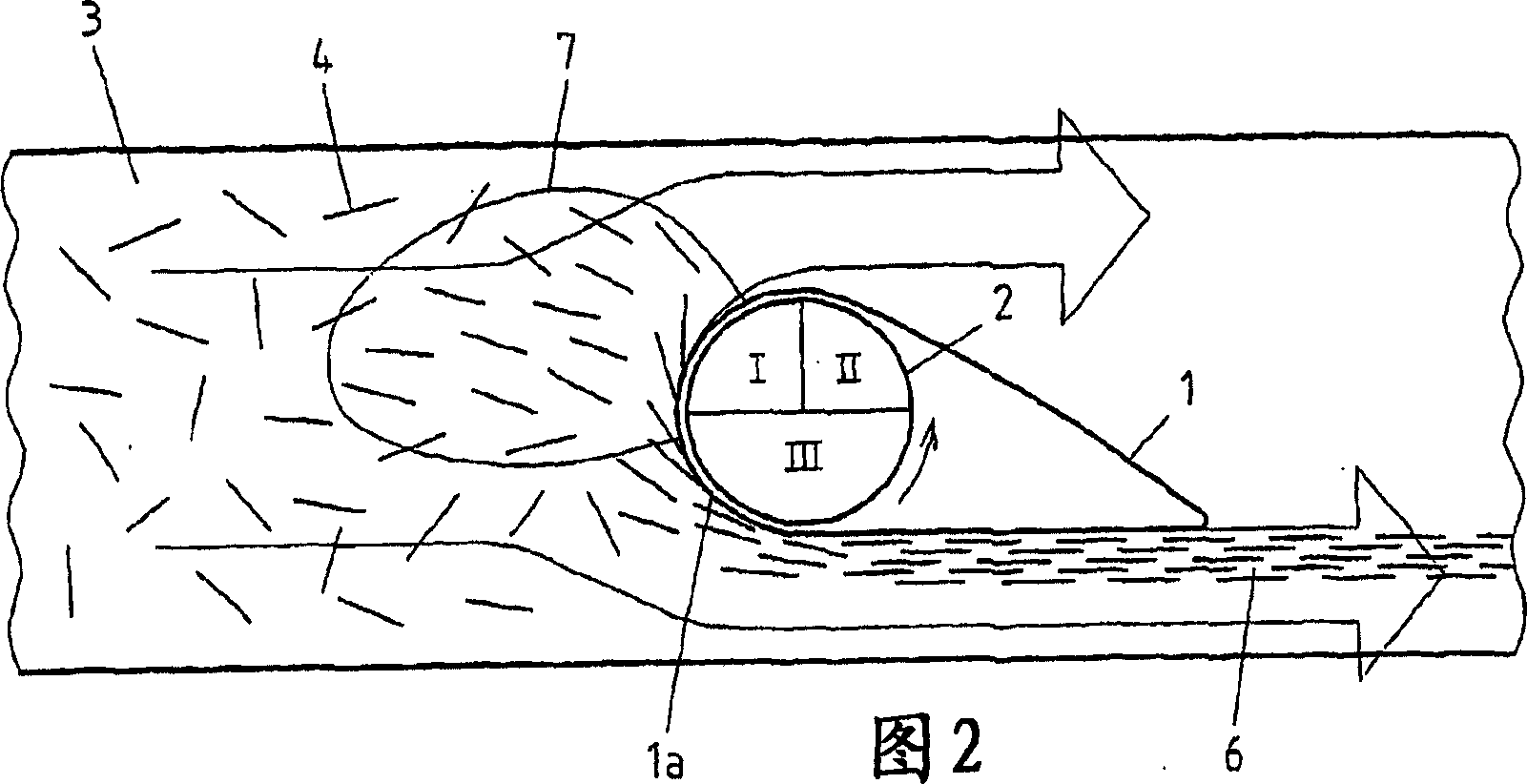

[0036] A device for orienting magnetizable particles in a pasty material is shown in FIGS. 1 a and 1 b. The device has an orienting body 1 in the form of a hollow profile, which consists of a non-magnetic material. According to the cross-sectional view in FIG. 1 a , the hollow profile comprises a circular arc-shaped front part 1 a which tapers in a straight line via two side parts 1 c in the direction of a rear surface part 1 b. Inside the orienting body 1 is arranged a magnet arrangement 2, which is configured as a cylindrical roller mounted on a rotatable support concentrically with respect to the arc-shaped front surface portion 1a. The magnet roller 2 is equipped with permanent magnets along its longitudinal axis and is rotated, for example, by one or more electric motors (not shown). Thus a rotating, i.e. periodically varying, magnetic field acting on the particles contained in the pasty material is produced, which is divided into three regions I, II, III with partial fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com