Dual openable stopper for high-temperature and pressure pipeline blocking construction

A high temperature and high pressure, plugging head technology, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problem that the sealing layer cannot be used, the supporting force cannot be satisfied, and the rubber sheet seal cannot meet the plugging needs. and other problems to achieve the effect of improving one's own strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

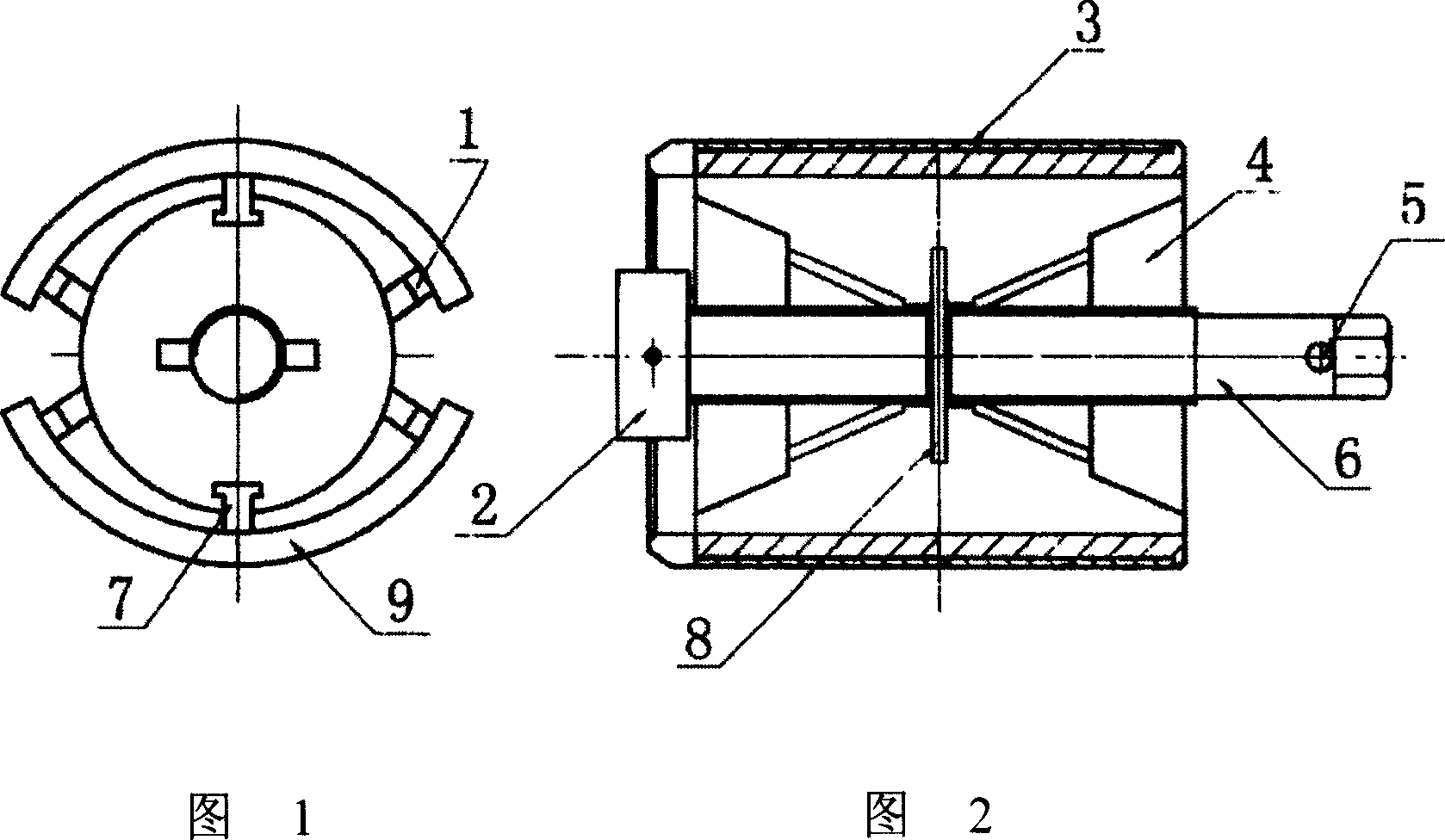

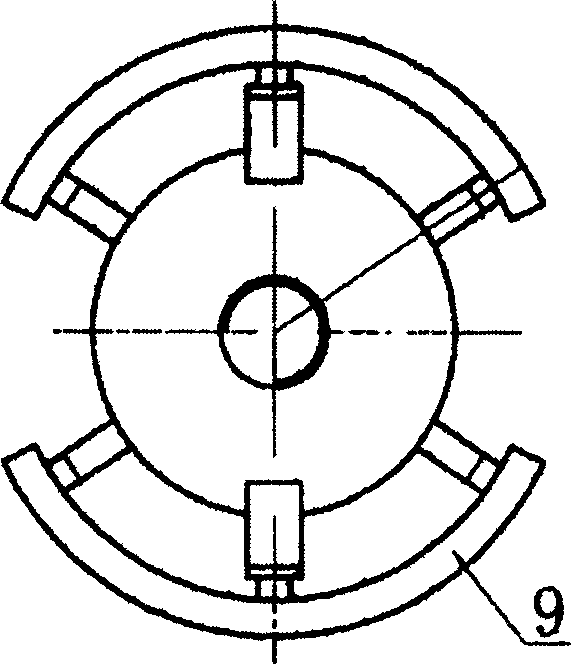

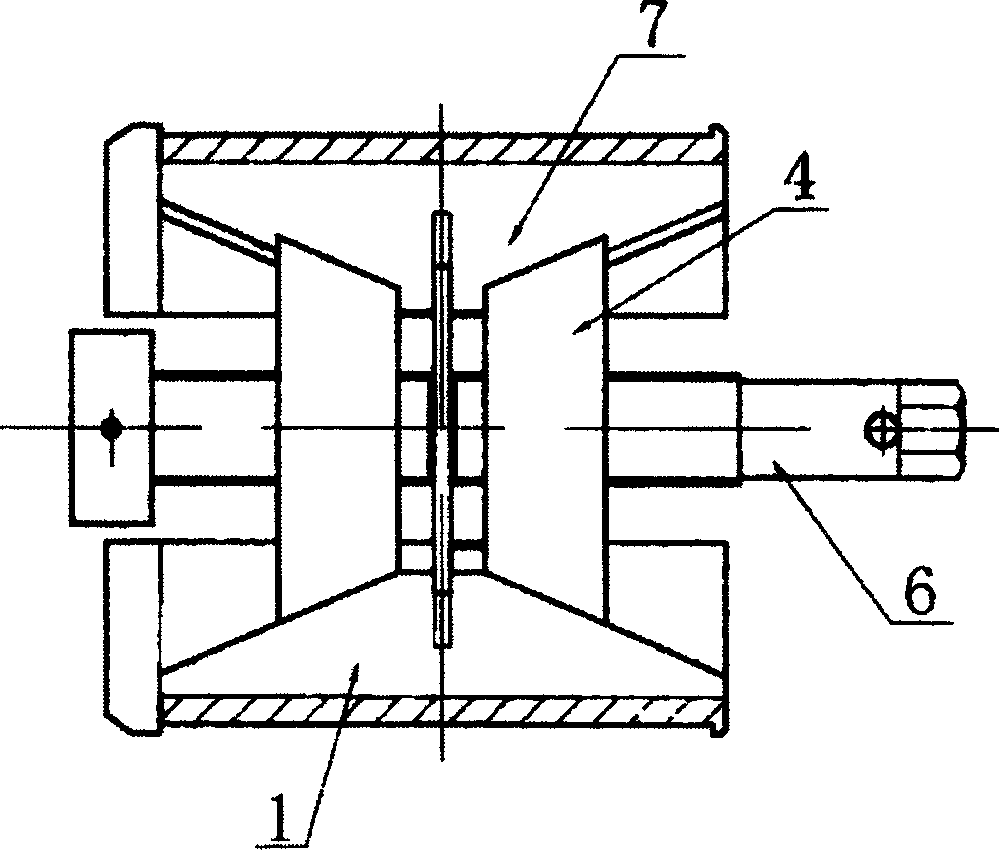

[0016] The two-opening plugging head for high temperature and high pressure pipeline plugging construction is composed of plugging head and transmission parts. Refer to Figure 1-4, where:

[0017] The plug is two oppositely convex strip arc plates 9, and the longitudinal oblique rib 7 is fixed in the center of the inner side of the strip arc plate. In addition, a longitudinal support frame 1 is respectively fixed on both sides of the inner side of the strip-shaped arc plate, and the support frame is also in the shape of an isosceles triangle. The bar-shaped arc plate is made of high-quality carbon structural steel as the skeleton, and a sealing layer 3 of rubber, aluminum, lead, copper or polyurea is fixed on the outer surface of the skeleton.

[0018] The transmission part is composed of a lead screw 6 with reverse thread and two tapered thread lock nuts 4 screwed on it. The plug and the transmission part are slidingly connected with the "T" groove on the surface of the tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com