Decoupling detecting device for gyroscope scale factor and input shaft default angle

A technology for scaling factor and testing equipment, applied in gyroscope/steering sensing equipment, gyro effect for speed measurement, speed/acceleration/shock measurement, etc., can solve high equipment use and maintenance costs, complex equipment, and machining errors and other problems, to achieve the effects of constraining and fixing the seat, improving the calculation accuracy of parameters, and avoiding transmission errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

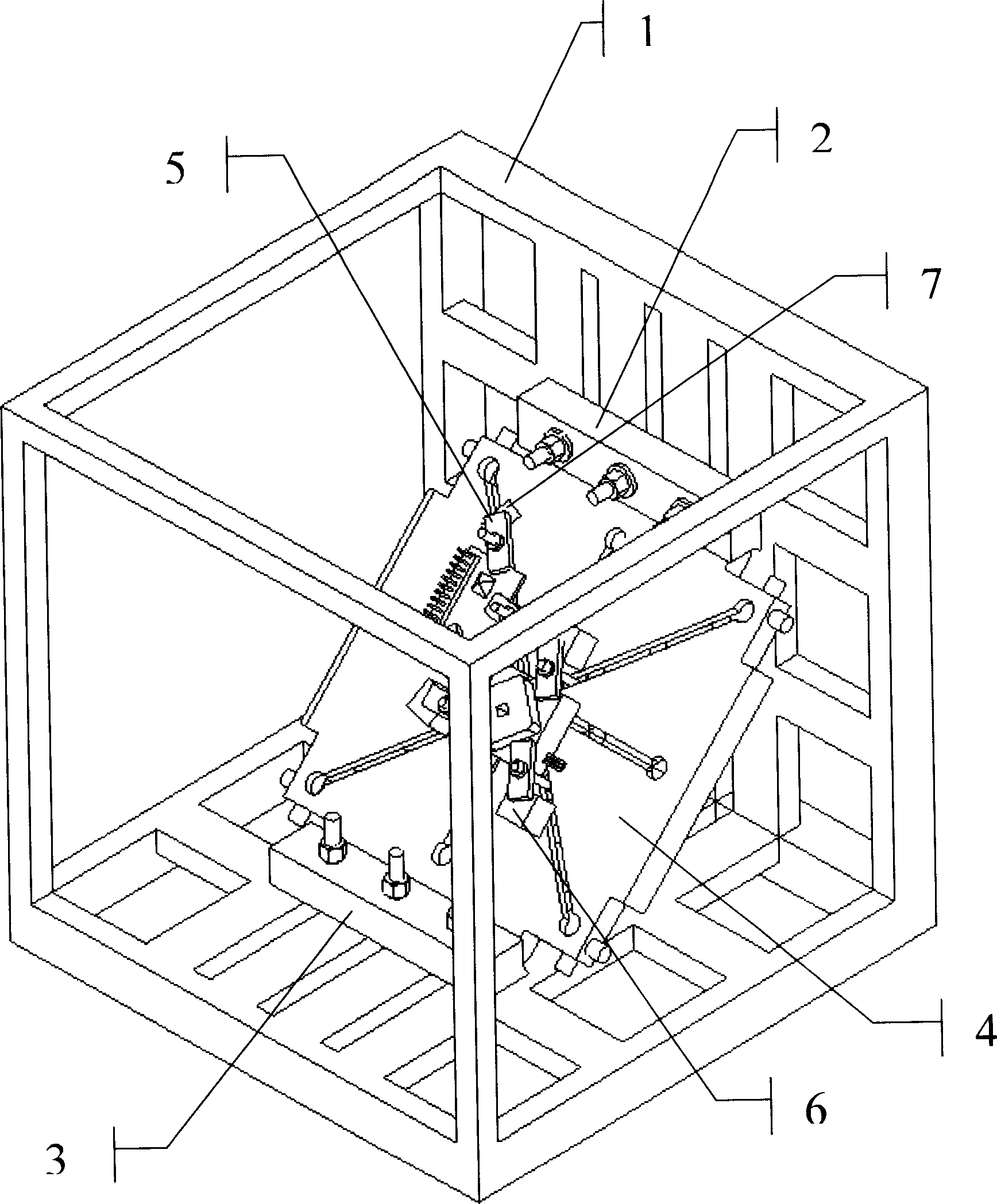

[0031] Such as figure 2 As shown, the present invention is made up of hexahedron frame 1, back clip bar 2, bottom surface clip bar 3, seat plate 4, pressure plate 5, large cushion block 6, and small cushion block 7, and hexahedron frame 1 is placed on the turntable horizontal platform, and hexahedron frame 1 provides a support for the rear clamping bar 2 and the bottom clamping bar 3, and the two sets of clamping bars provide restraint force to the seat board 4 in the space, clamp the seat board 4 and fix it at a certain inclination angle. Such as Figure 11 As shown, no matter whether the thickness of the pressure-resistant part of the gyroscope is large or small, as long as a cushion block with the same thickness is selected, the gyroscope can be pressed tightly with the pressure plate 5 and fixed on the seat plate 4, so that the gyroscope can be kept in space. A fixed inclination angle is accurately measured, and then the single-axis rate turntable is used to provide high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com