Universal probe device for electronic module detecting system

A technology of electronic components and probes, applied in the field of probe devices for panel array testing, can solve the problems of probe frame production and design costs, production capacity and manpower waste, time-consuming, etc., and achieve simple and fast design and manufacture, and fast replacement steps , Low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

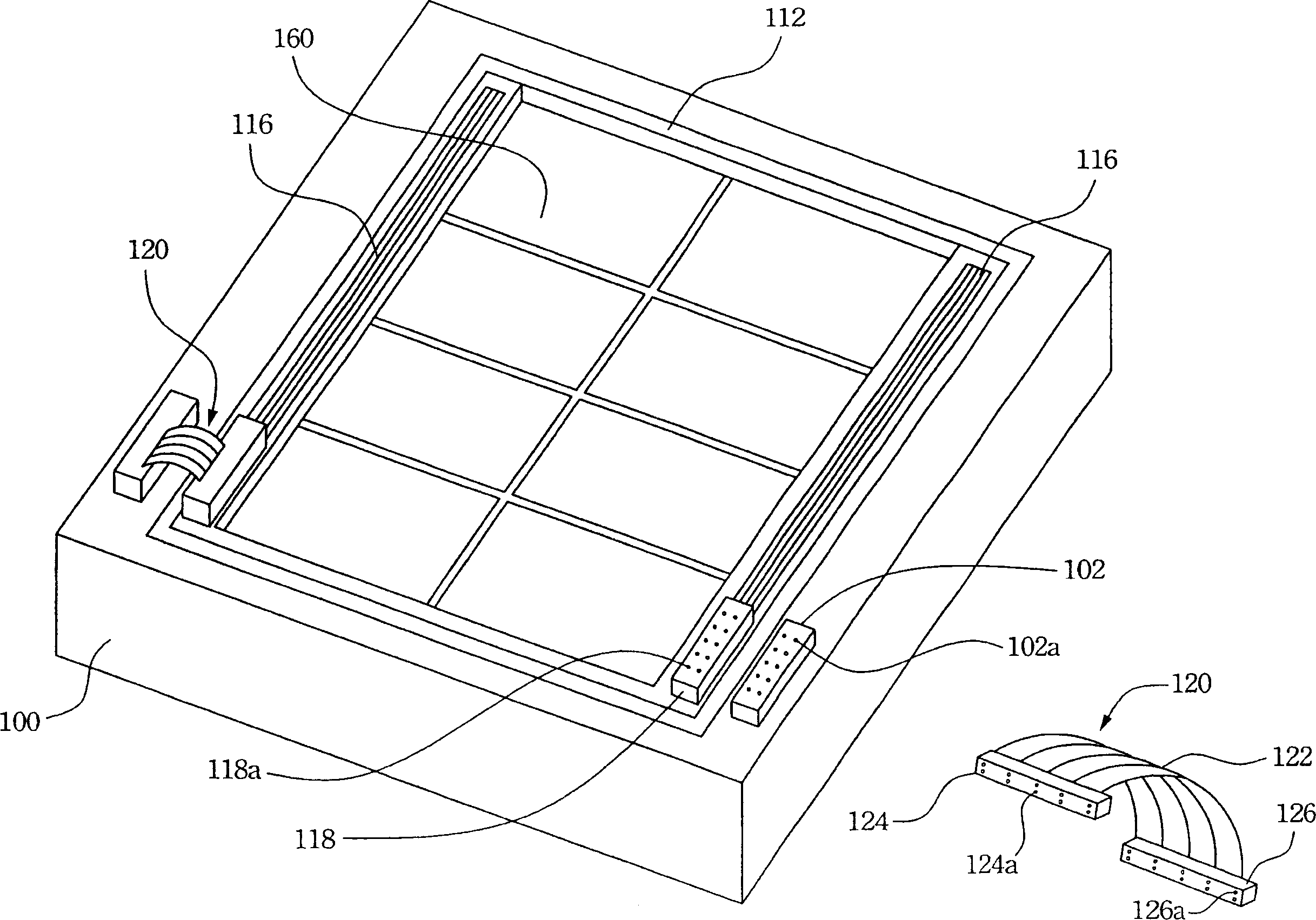

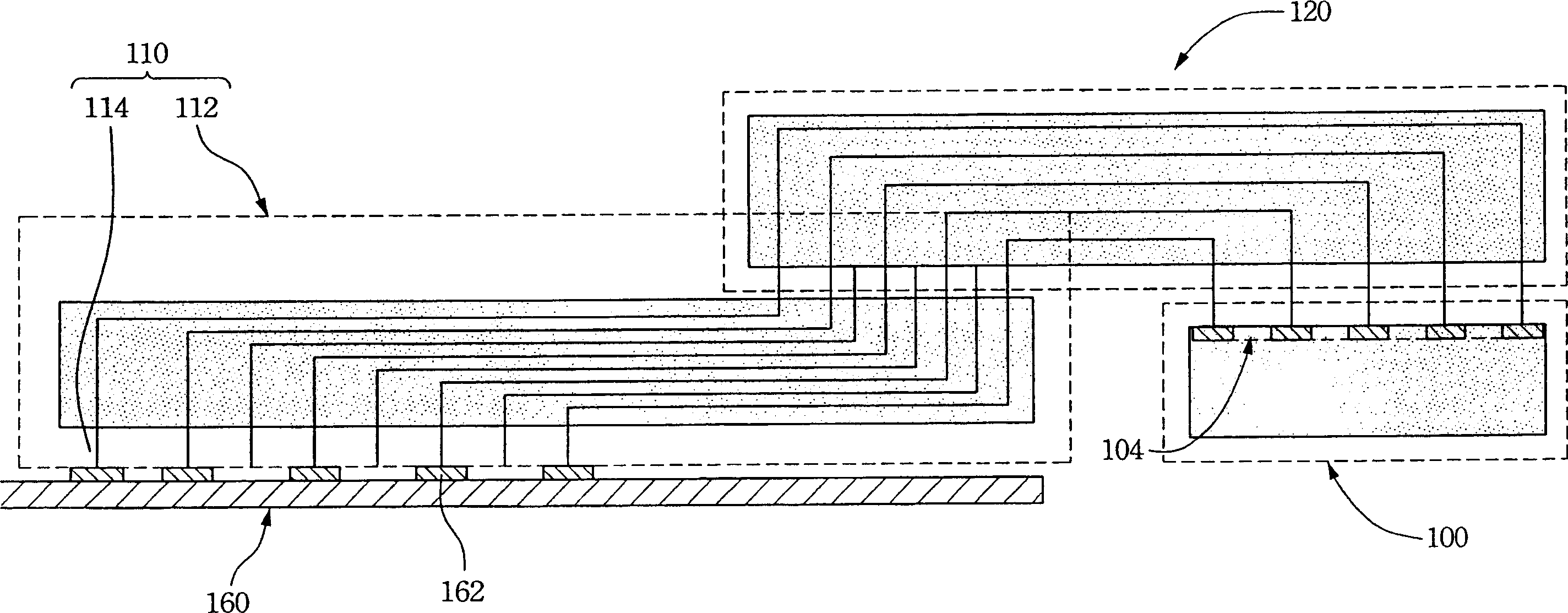

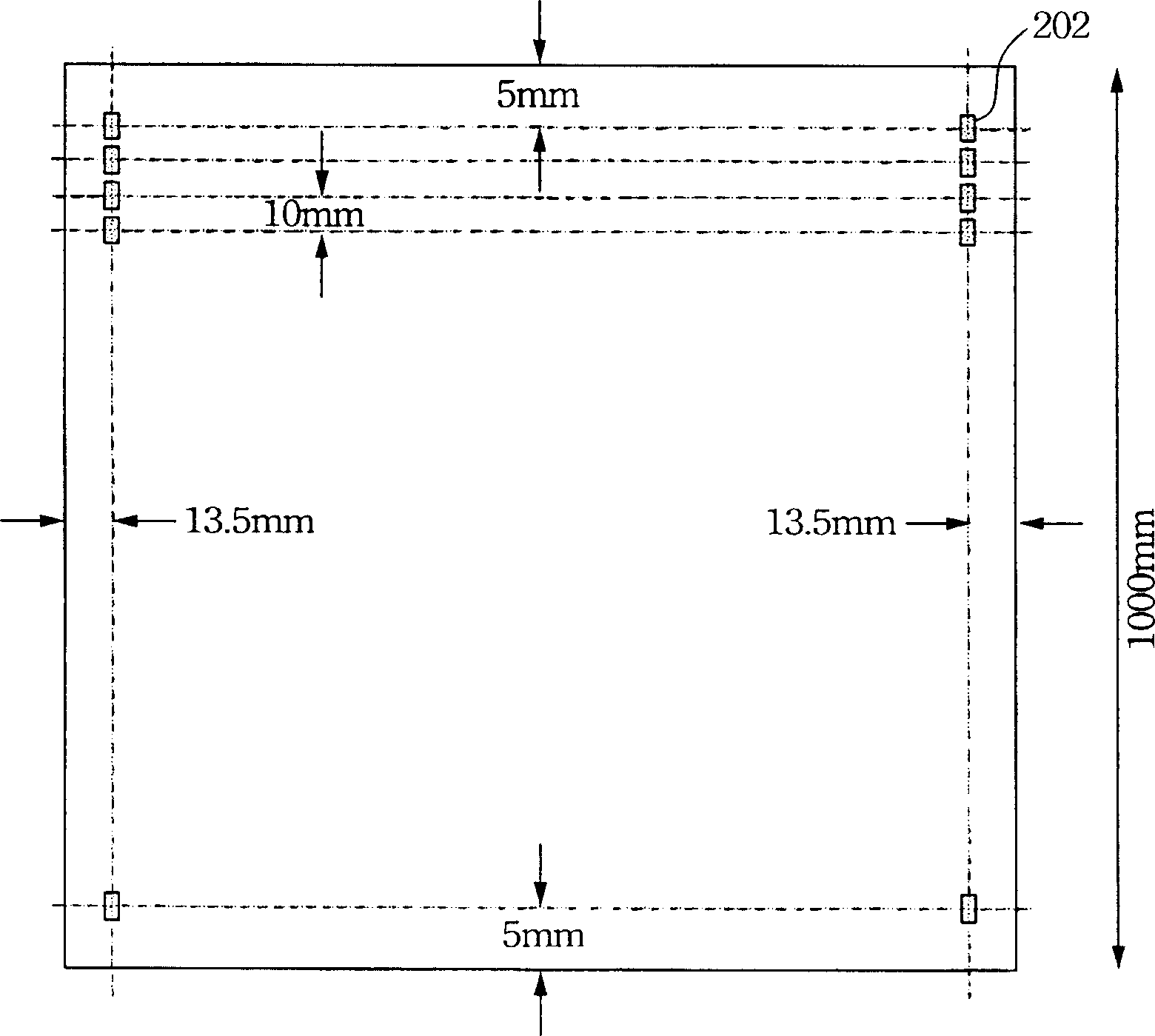

[0036] The present invention discloses a probe device for system testing of electronic components. A shared probe unit is provided to perform test steps for display panels of different sizes and specifications. When changing a product line for testing, only a circuit switching device needs to be replaced, which avoids the traditional need for additional design. , the inconvenience of making and replacing the probe frame and a large amount of cost. In order to make the narration of the present invention more detailed and complete, refer to the following description and cooperate Figure 1a and Figure 1b icon.

[0037] refer to Figure 1a , which shows a schematic diagram of a preferred embodiment of a probe device for system testing of electronic components according to the present invention. The probe device of the electronic component system test of the present invention includes a probe unit 110 (shown in Figure 1b ) and a line switching device 120. The probe unit 110 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com