Method of pattern coating

A coating and patterning technology, which is applied in the direction of conductive pattern formation, coating, and liquid coating on the surface, can solve the problems of no public use, etc., and achieve low cost, significant cost-effectiveness and productivity benefits, and guaranteed costs. Effect

Inactive Publication Date: 2006-08-23

EASTMAN KODAK CO

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The prior art does not disclose the use of any differential wetting device for the roll-to-roll manufacture of coated webs of soft materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

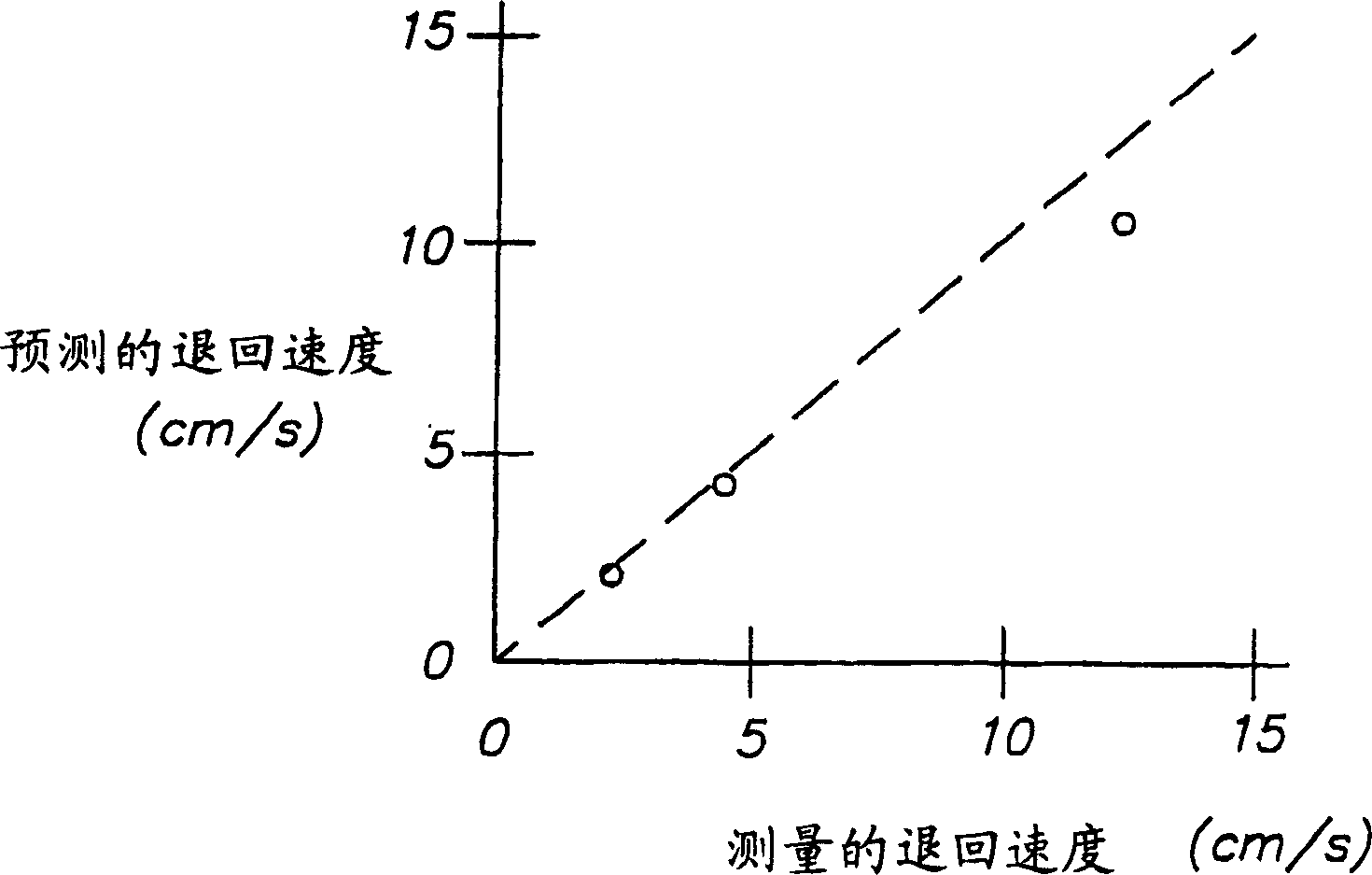

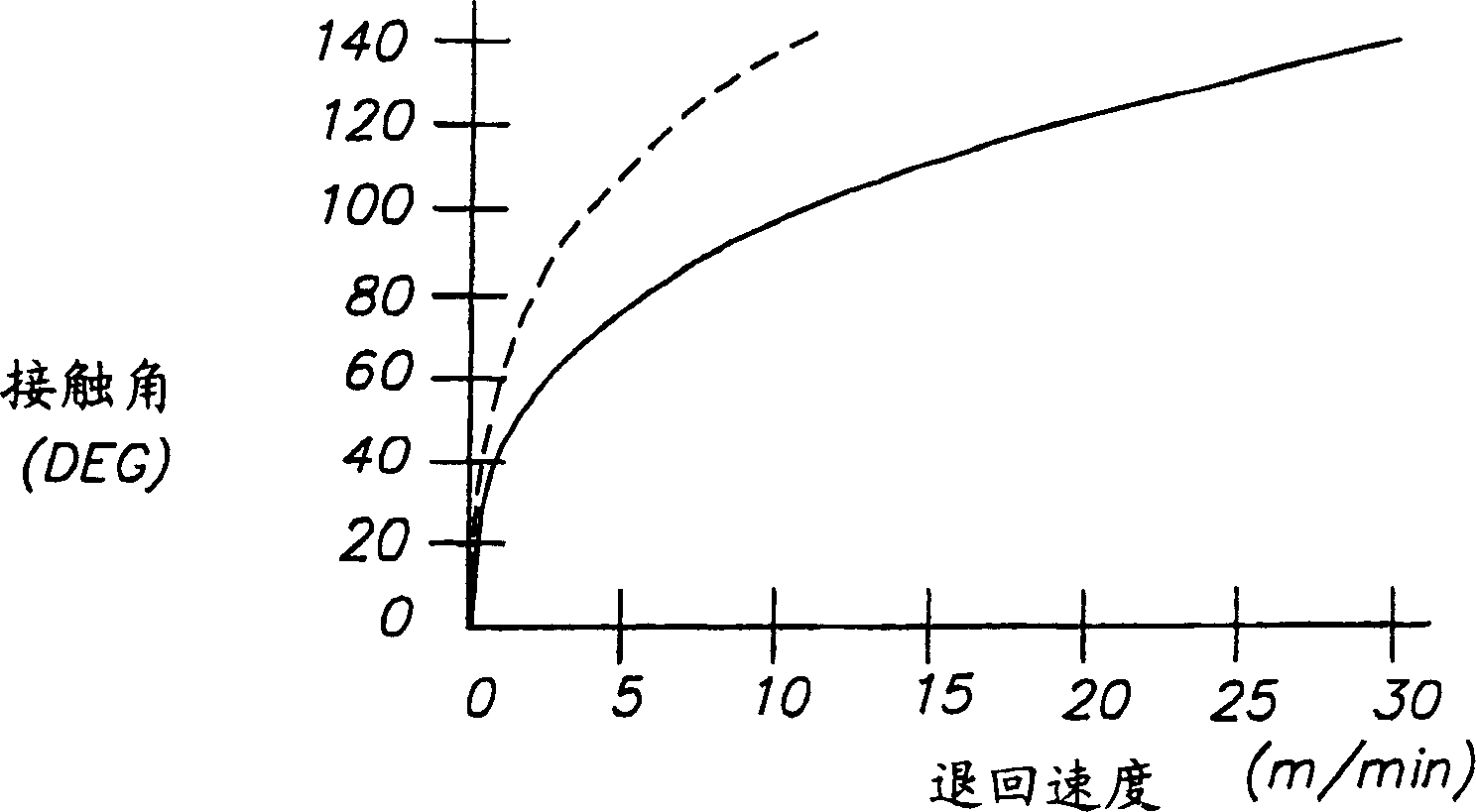

[0041] Example 1: Manual coating using aqueous glycerin (20, 50 and 100 cP)

Embodiment 2

[0042] Example 2: Manual coating using PEDOT / PSS (cholesteric liquid crystal dispersion in gelatin).

[0043] Roller-to-roller bead coating:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A method of coating well defined discrete areas of a flexible substrate by creating a lyophobic pattern on the surface of the web to leave a desired pattern of lyophilic areas. A layer of coating solution is laid down over the patterned web, the solution withdrawing from the lyophobic areas and collecting on the lyophilic areas.

Description

field of invention [0001] The present invention relates to the field of coating, and in particular to the roll-to-roll coating of well-defined discrete areas of a continuous web (web) of material. Background technique [0002] It is known to use the fundamental principle of differential wetting to condition liquids on solid supports such as silicon wafers. The general principle consists in the spontaneous movement of liquid from the lyophobic (solventphobic) regions of the substrate or carrier to the lyophilic (solventophilic) regions. [0003] WO 02 / 38386 discloses a method and apparatus for patterning using a temperature gradient. The temperature gradient is used to condition the liquid after coating. [0004] EP 0882593 discloses a method of forming a hydrophobic / hydrophilic front side of an inkjet printer. Hydrophobic surfaces around the printhead nozzles are needed to repel ink from the nozzles, and hydrophilic areas are needed to pull ink away from the hydrophobic a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B05D5/04B41M1/00B41M1/04B41M1/06B41M1/12B41M3/00B41M7/00H01L51/40H05K1/00H05K3/12

CPCB41M7/00Y10T428/24355H05K1/0393H05K3/1208B41M1/12Y10T428/31B41M1/06B41M3/003H01L51/0004H05K2203/1545B41M7/0036B82Y30/00B41M7/0054B41M1/00B41M1/04H05K2203/1173H10K71/13B05D5/04

Inventor C·L·鲍尔E·A·西米斯特T·D·布拉克E·邦尼斯特

Owner EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com