Alloy pipe material thermal extrusion method and extrusion mould

A technology of hot extrusion and alloy pipe, which is applied in the field of hot extrusion of pipes to achieve the effects of good product quality, low cost and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure and extrusion method of the alloy pipe hot extrusion die of the present invention will be further described in conjunction with examples below.

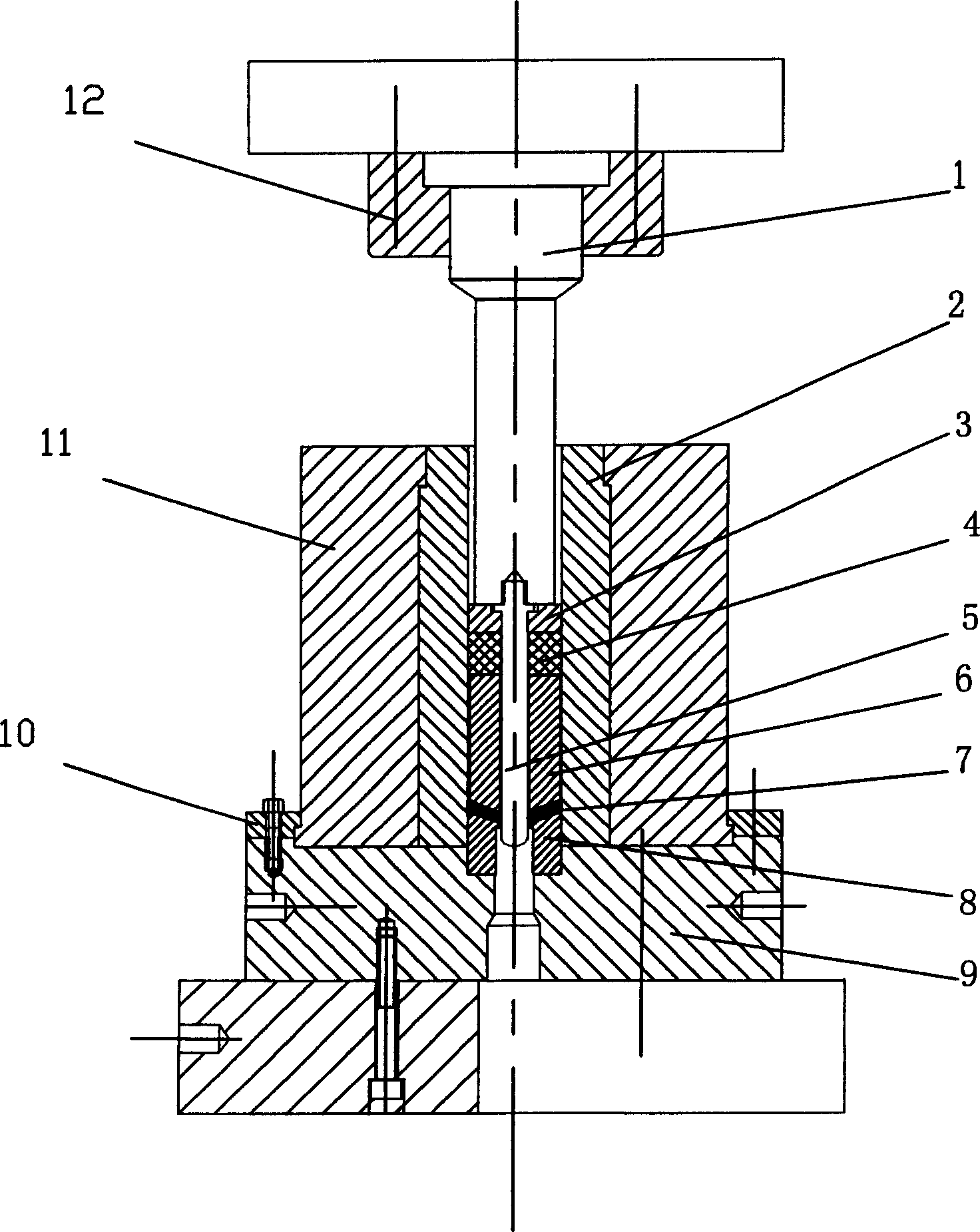

[0016] Such as figure 1 As shown, an alloy pipe hot extrusion method and an extrusion die include an extrusion shaft 1, an extrusion cylinder 2, an extrusion pad 3, a graphite pad 4, an extrusion rod 5, an extrusion blank 6, and a glass pad 7, Die 8, bottom plate 9, pressing plate 10, extrusion cylinder seat 11, fixed seat 12. The extrusion cylinder 2 is arranged in the extrusion cylinder seat 11, and is fixed on the base plate 9 with screws through the pressure plate 10, and the die 8 is arranged at the lower end of the extrusion cylinder 2, and is fixed in the groove on the base plate 9, and the base plate 9 is fixed on the base of the extruder by bolts, put the heated glass pad 7 on the die 8, install the heated extrusion blank 6, then put the graphite pad 4 and the extrusion pad 3, and extrude The pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com