Brightness-enhanced multilayer optical film with low reflectivity for display and organic light emitting diode display using the same

一种多层光学膜、低反射率的技术,应用在有机半导体器件、光学、光学元件等方向,能够解决发光元件光输出效率下降、发光元件亮度性能差等问题,达到光线输出效率高、亮度性能高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

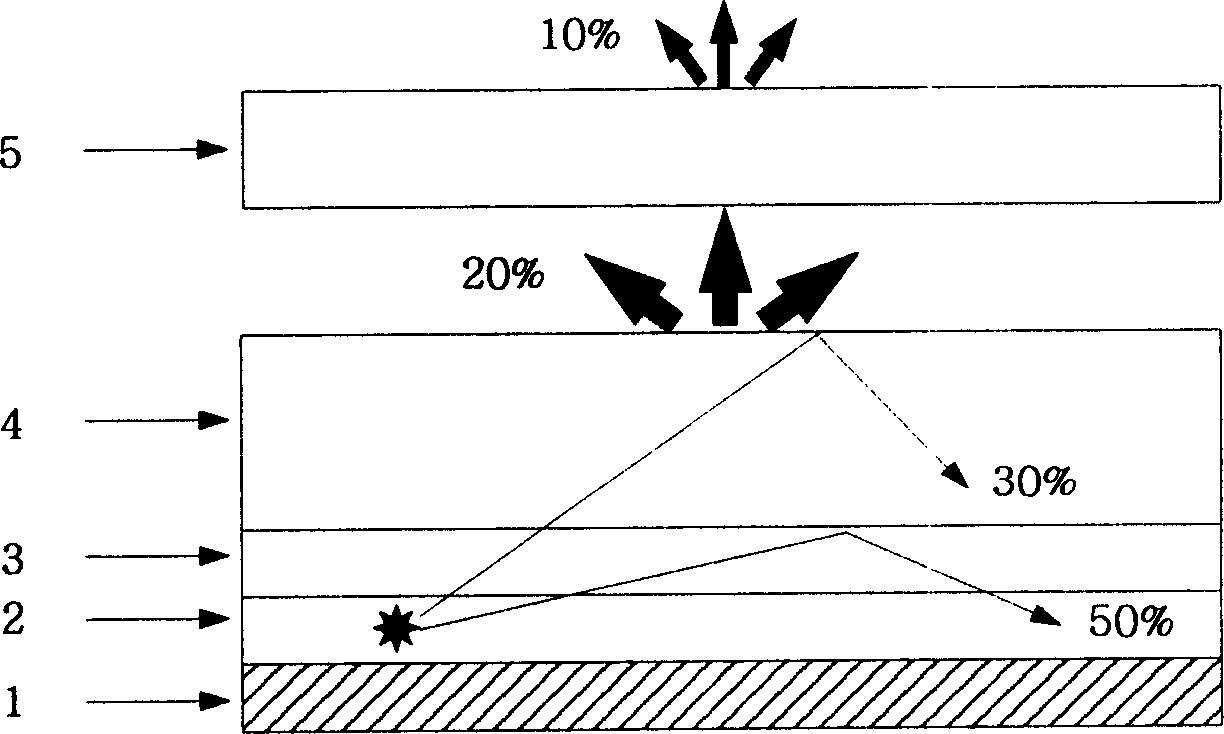

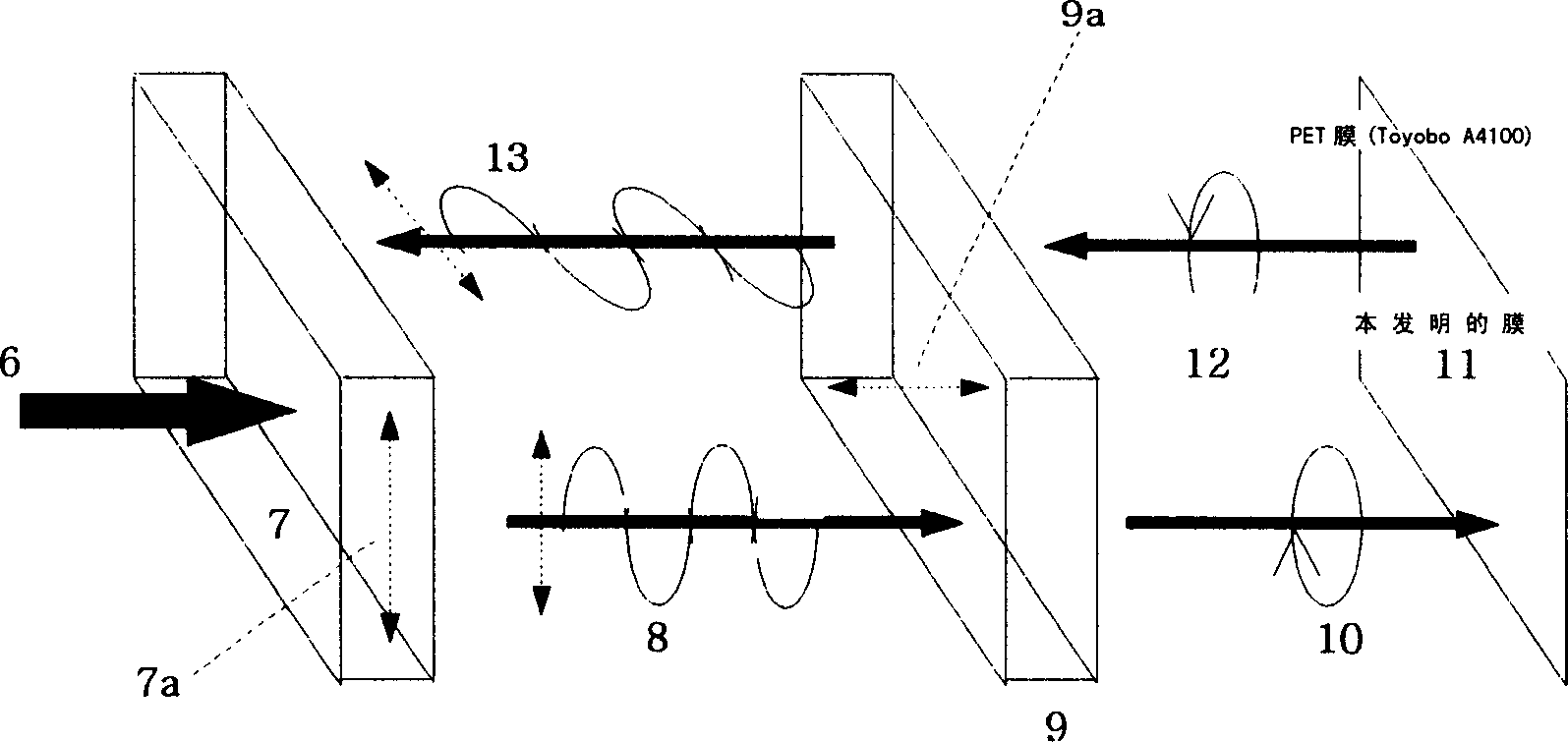

[0084] A 100 μm thick polyethylene terephthalate (PET) film was used as a transparent substrate. The coating liquid for the light diffusion layer was prepared in the following steps. First, 200 parts by weight of light-diffusing particles with an average diameter of 5 μm are sufficiently stirred and dispersed in a mixture containing 300 parts by weight of isopropanol (IPA), 300 parts by weight of methyl ethyl ketone (MEK), 200 parts by weight of toluene, and 100 parts by weight of cyclopentane. In a mixed solvent of ketone, a dispersion of light diffusing particles is obtained. 100 parts by weight (solid content) of thermosetting acrylic resin (Aekyung Chemical, Korea) was mixed with the dispersion, and then stirred for 3 hours to obtain a particle-dispersed resin solution. One hour before forming the light diffusion layer, 25 parts by weight of an isocyanate curing agent (Aekyung Chemical, Korea) was added to the resin solution to prepare a coating liquid for the light diffusion ...

Embodiment 2

[0086] A multilayer optical film was prepared in the same method as in Example 1, except that the amount of light-absorbing particles was 150 parts by weight to form a light-absorbing layer on the light-diffusing layer.

Embodiment 3

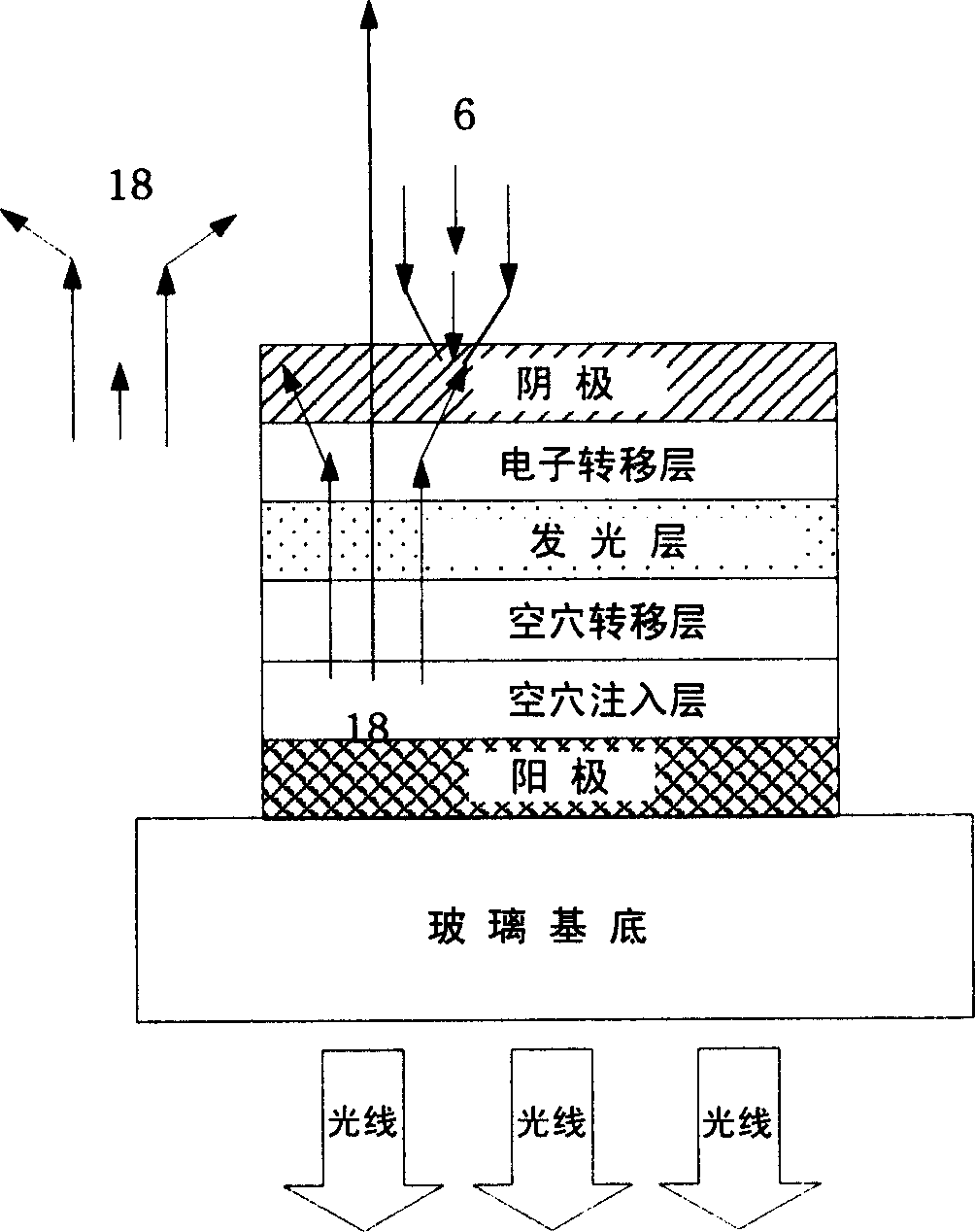

[0088] The optical film prepared in Example 1 or 2 was laminated to manufacture an OLED display in the following manner: The adhesive layer located on the opposite side of the light-absorbing layer of the optical film was attached to a 14.1-inch OLED display (Samsung Electronics, Korea) transparent substrate (indium titanium oxide ( ITO) glass) on the top. Measure the brightness of white light at 500lx.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com