Ceria abrasive for cmp

A chemical-mechanical and cerium-oxide technology, which is applied in the direction of polishing compositions containing abrasives, other chemical processes, chemical instruments and methods, etc., can solve problems such as the use and amount of chemical additives that are not specified in detail, and achieve highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

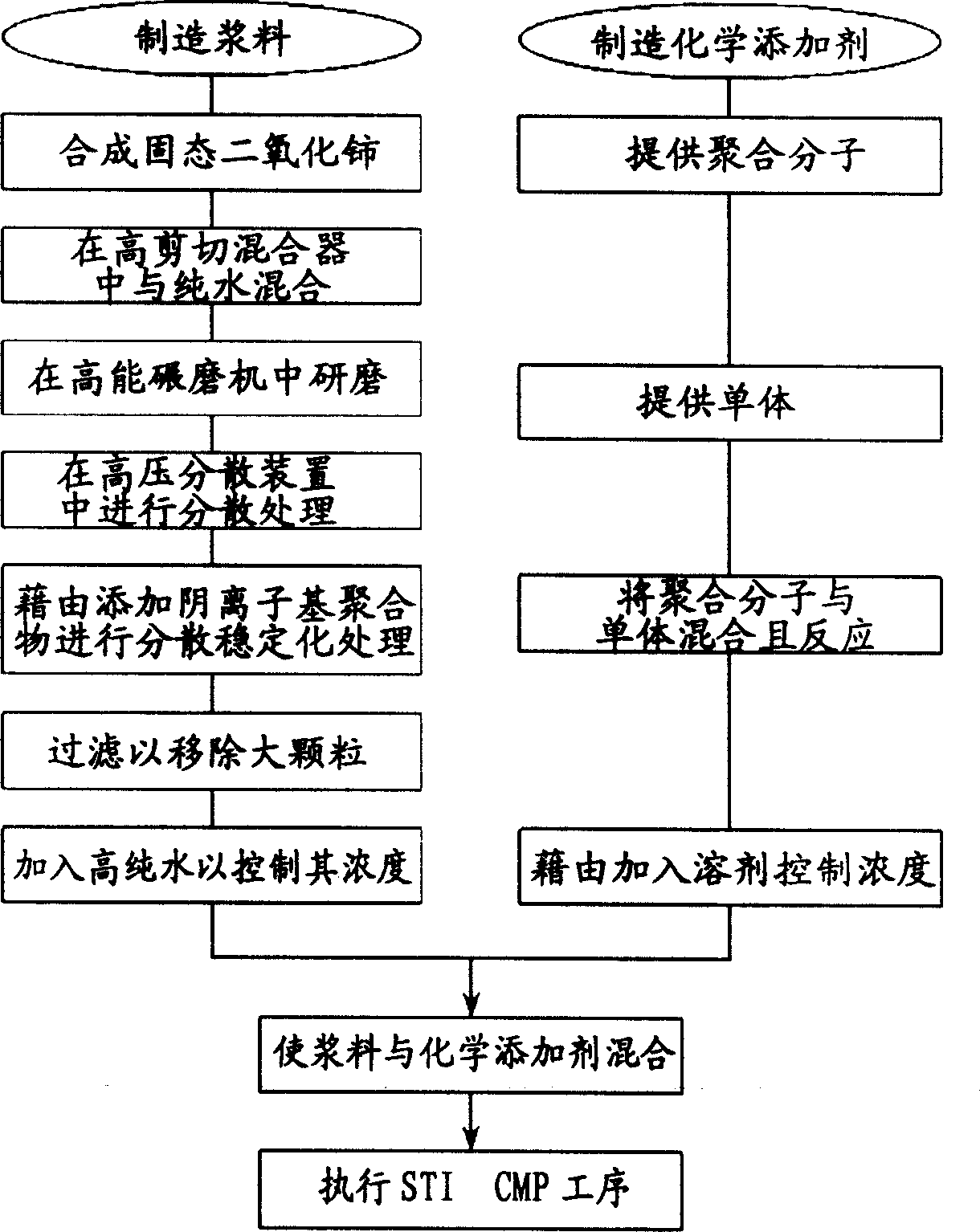

[0049] 50 kg of synthetic high-purity ceria powder was mixed with 150 kg of high-purity water in a high-shear mixer. Subsequently, the mixture was ground in a high-energy mill to control its particle size, and dispersed by a high-pressure dispersion stabilizer. Next, polymethacrylamine (trade name: Darvan C, available from R.T. Vanderbilt Co.) as an anionic polymer was added in an amount of 1% by weight of the ceria powder. Then, after obtaining a 2% by weight ceria slurry by adding an additional 480 kg of high-purity water to the mixture and stirring, by mixing 2 kg of a 10% by weight ceria slurry with 8 kg of high-purity water 10 kg of 2% by weight ceria slurry was obtained to prepare a final slurry sample. That is, the concentration of abrasive particles was controlled to be 2% by weight.

[0050] Independently of the above steps, after mixing 0.3kg of polyacrylic acid (PAA) with 0.05kg of acrylamide and a very small amount of high-purity water and reacting them, it is ma...

Embodiment 2 to 10

[0053] Although the slurry produced in the same manner as in Example 1 was used in Examples 2 to 10, compounds described in Table 1 as chemical additives were mixed with the above slurry. The mixing ratio of the two is the same as in Example 1, which is also 1:1.

[0054] polymer molecule

Embodiment 11

[0088] In order to determine the impact of the concentration of chemical additives in the CMP abrasive of the present invention on the CMP process, the chemical additives used for low-density and high-density patterns were respectively used to calculate the polymerization of 3%, 5% and 10% by solvent weight. The addition of molecules and monomeric compounds to manufacture. The results of the polishing properties of the abrasives according to the respective chemical additives are shown in Table 4.

[0089] 10% by weight

5% by weight

3% by weight

low density pattern

chemical additives

oxide removal rate

(Angstrom / min)

2310

2780

3170

Nitride film removal rate

(Angstrom / min)

45

53

59

high density pattern

chemical additives

Oxide film removal rate

(Angstrom / min)

2010

2530

2800

Nitride film removal rate

(A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com