Production method of small section flexible optical fibre bundle for transmitting image using acid soluble method

An optical fiber image transmission bundle, acid-soluble technology, applied in the direction of manufacturing tools, optical fiber bundles, glass manufacturing equipment, etc., can solve the problem of low effective transmittance of optical fiber bundles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of raw glass rods: According to the composition requirements, the glass batch materials of core material, skin material and acid-soluble material are made, melted and clarified in a platinum crucible, and drawn into glass rods. The diameter of the core glass rod is 30mm, the diameter of the skin glass rod is 28mm, and the diameter of the acid-soluble glass rod is 18mm;

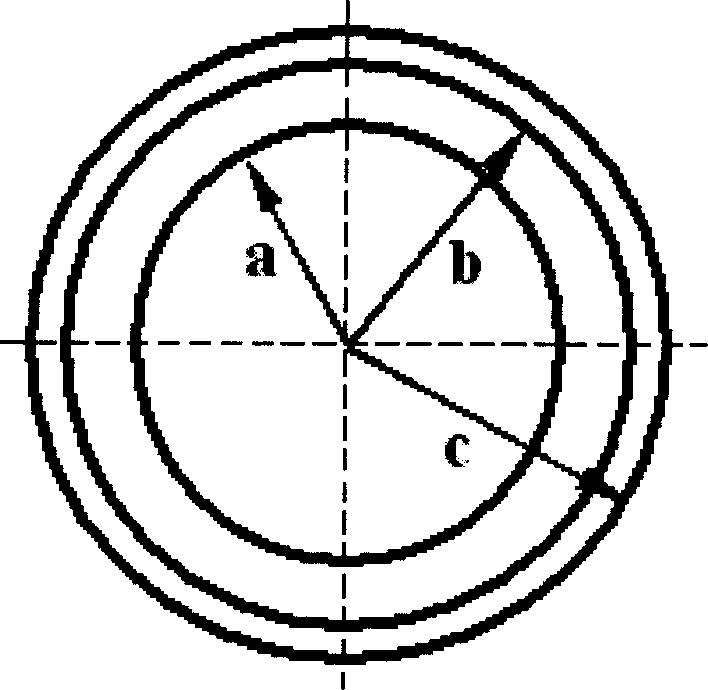

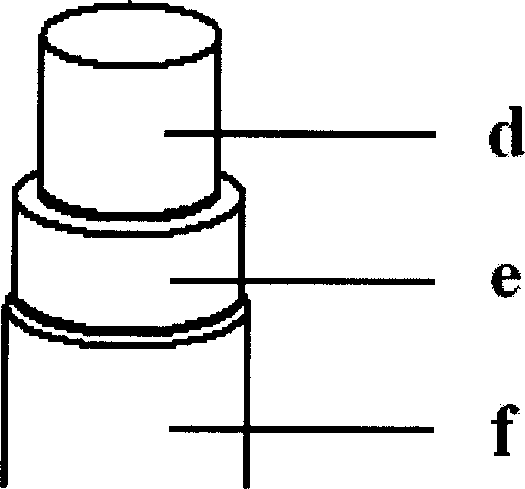

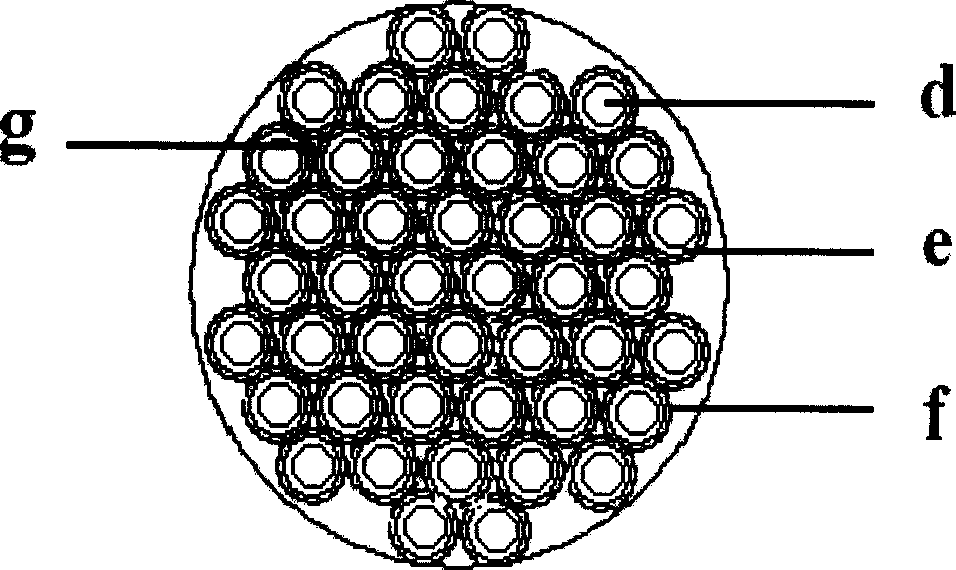

[0029] (2) Manufacture of coaxial three-layer monofilament: Add core glass, skin glass and acid-soluble glass rods into a three-set crucible and heat and melt at the same time. The three sets of crucibles are placed in an electric furnace, and the temperature of the electric furnace is divided. , middle and lower areas, control the temperature of the three areas at 1280°C, 960°C and 820°C respectively, then it can be drawn from the crucible and then drawn into three layers at the mouth of the three sets of crucibles. Axial monofilament; then draw three layers of coaxial monofilament at t...

Embodiment 2

[0035] (1) Preparation of raw glass rods: According to the composition requirements, the glass batch materials of core material, skin material and acid-soluble material are made, melted and clarified in a platinum crucible, and drawn into glass rods. The diameter of the core glass rod is 30mm, the diameter of the skin glass rod is 28mm, and the diameter of the acid-soluble glass rod is 18mm;

[0036] (2) Manufacture of coaxial three-layer monofilament: Add core glass, skin glass and acid-soluble glass rods into a three-set crucible and heat and melt at the same time. The three sets of crucibles are placed in an electric furnace, and the temperature of the electric furnace is divided. Three-layer, middle and lower areas are controlled, and the temperatures in these three areas are controlled at 1280°C, 960°C and 800°C respectively, and three-layer coaxial monofilaments can be drawn from the crucible, and the diameter of the monofilaments is 0.3 mm, the structure of monofilament...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com