Manufacturing method of metal surface multiple latent image and antifalse product made by said method

A production method and latent image technology, which can be applied to patterns characterized by light projection effects, printing of special varieties of printed matter, printing plates, etc. problem, to achieve the effect of enhanced anti-counterfeiting function and more information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

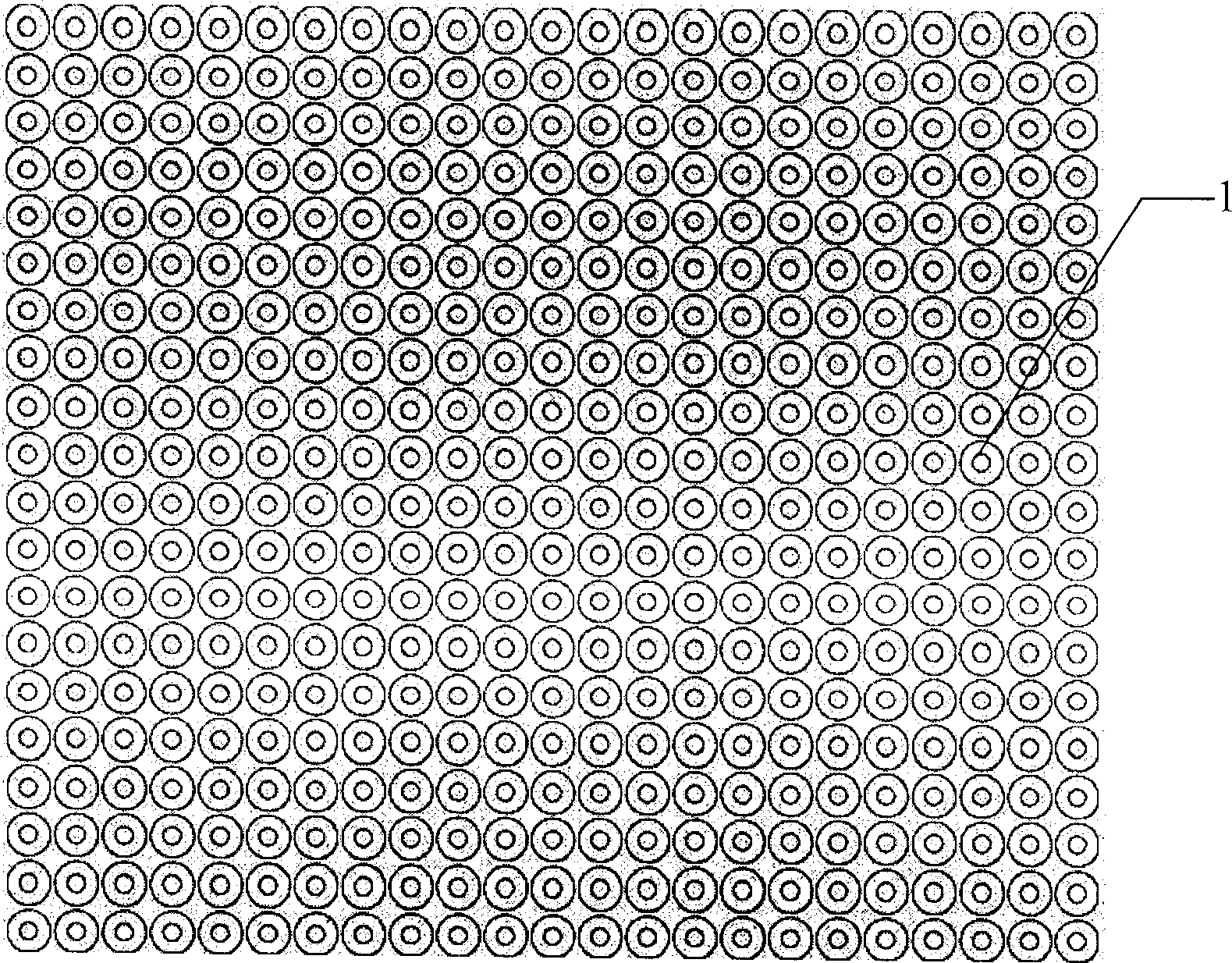

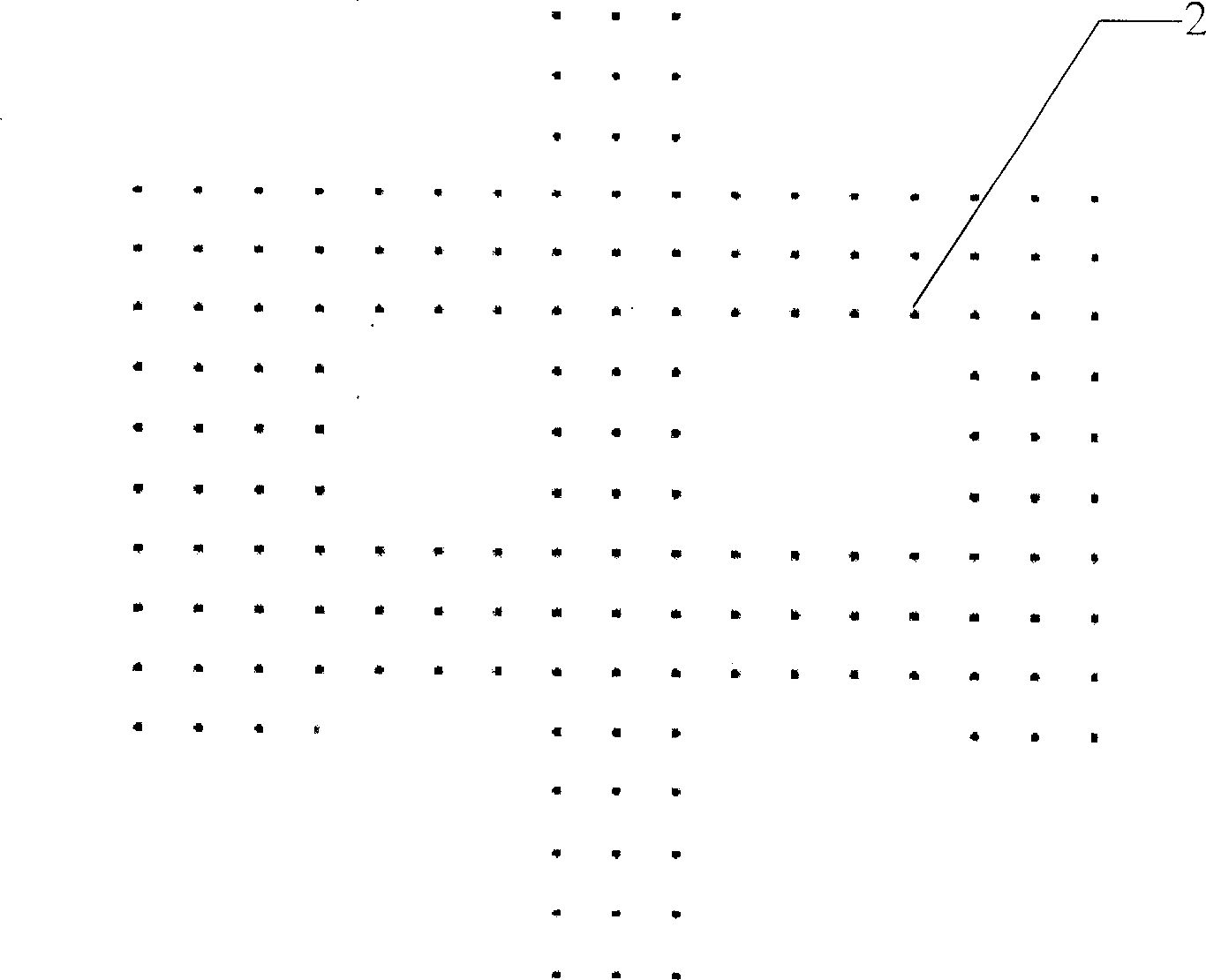

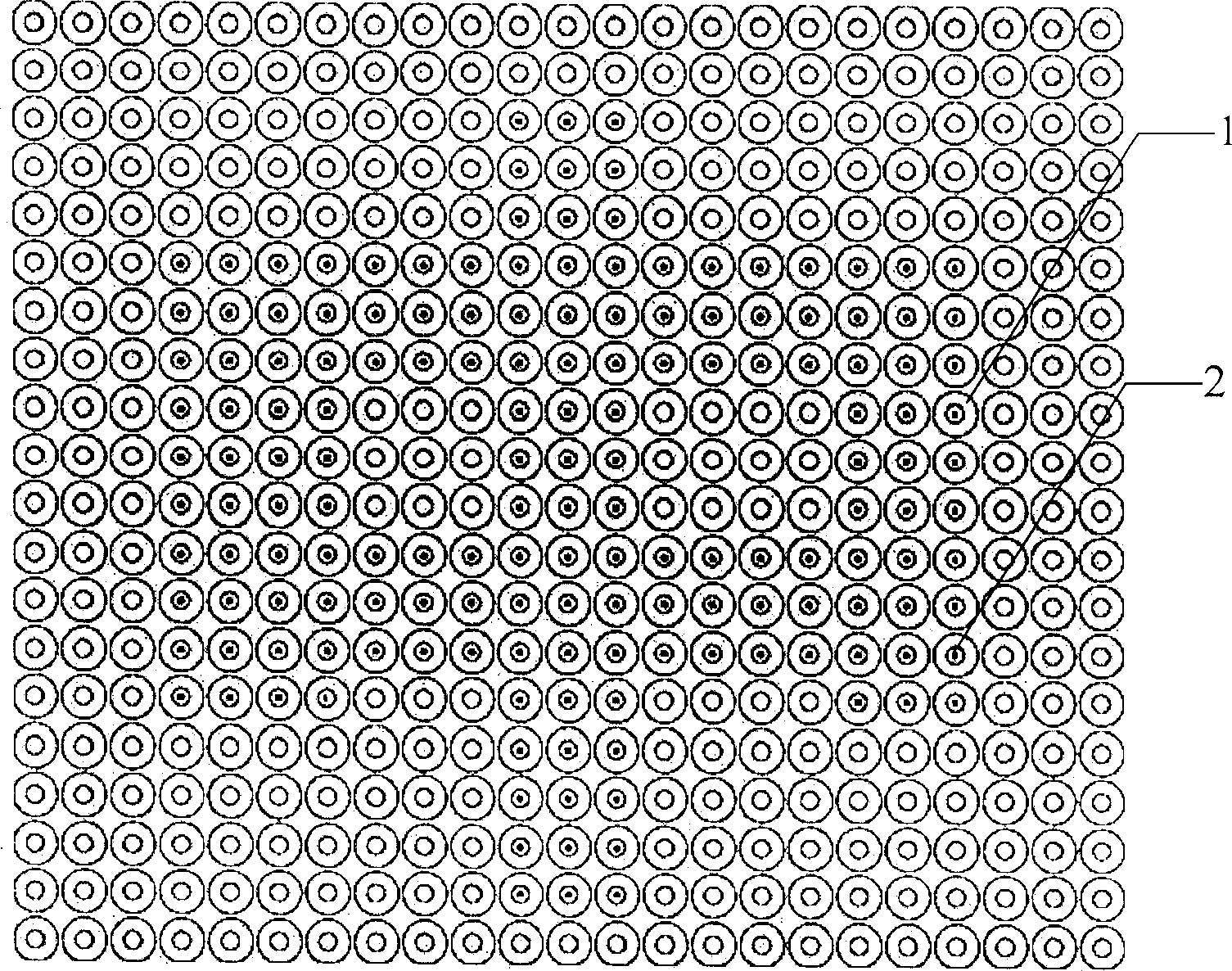

[0040] Example 1: A method for making multiple latent images on the metal surface, including designing patterns and engraving. The metal is a hard metal with a certain hardness. When designing the pattern, the metal surface is designed like figure 1 As shown in the densely distributed base point 1, the base point 1 is a circular altar shape with a large upper and a small lower concave. The design latent image multiplicity is five, and then the latent image pattern is decomposed into small pattern points, such as figure 2 , Figure 4 , Figure 6 , Figure 8 , Picture 10 As shown, the base point 1 is larger than the pattern point, and the pattern points of each double latent image pattern are designed in the same direction on the cone surface of the base point 1, as image 3 As shown, the pattern point 2 of the first double latent image is located on the bottom surface of the base point, such as Figure 5 As shown, the pattern point 3 of the second double latent image is located ...

Embodiment 2

[0043] Embodiment 2: The production steps and methods are the same as in embodiment 1. The base point 1 is designed and engraved into a conical shape when designing the pattern and engraving. It is only designed on the upper, lower, left and right parts of the cone of base point 1. With the pattern points of the quadruple latent image, a quadruple latent image is formed on the metal surface, and one latent image can be observed from four directions.

Embodiment 3

[0044] Example 3: Manufacturing steps and methods are as in Example 1. The base point 1 is designed and engraved into a hemisphere when designing the pattern and engraving. Only the upper and lower parts of the cone of base point 1 are designed and engraved The pattern points of the double latent image form a double latent image on the metal surface, and a double latent image can be observed from two directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com