Disinfection apparatus and method thereof

A technology of equipment and sterilizing fluid, applied in the field of transmission system, can solve problems such as limited life and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

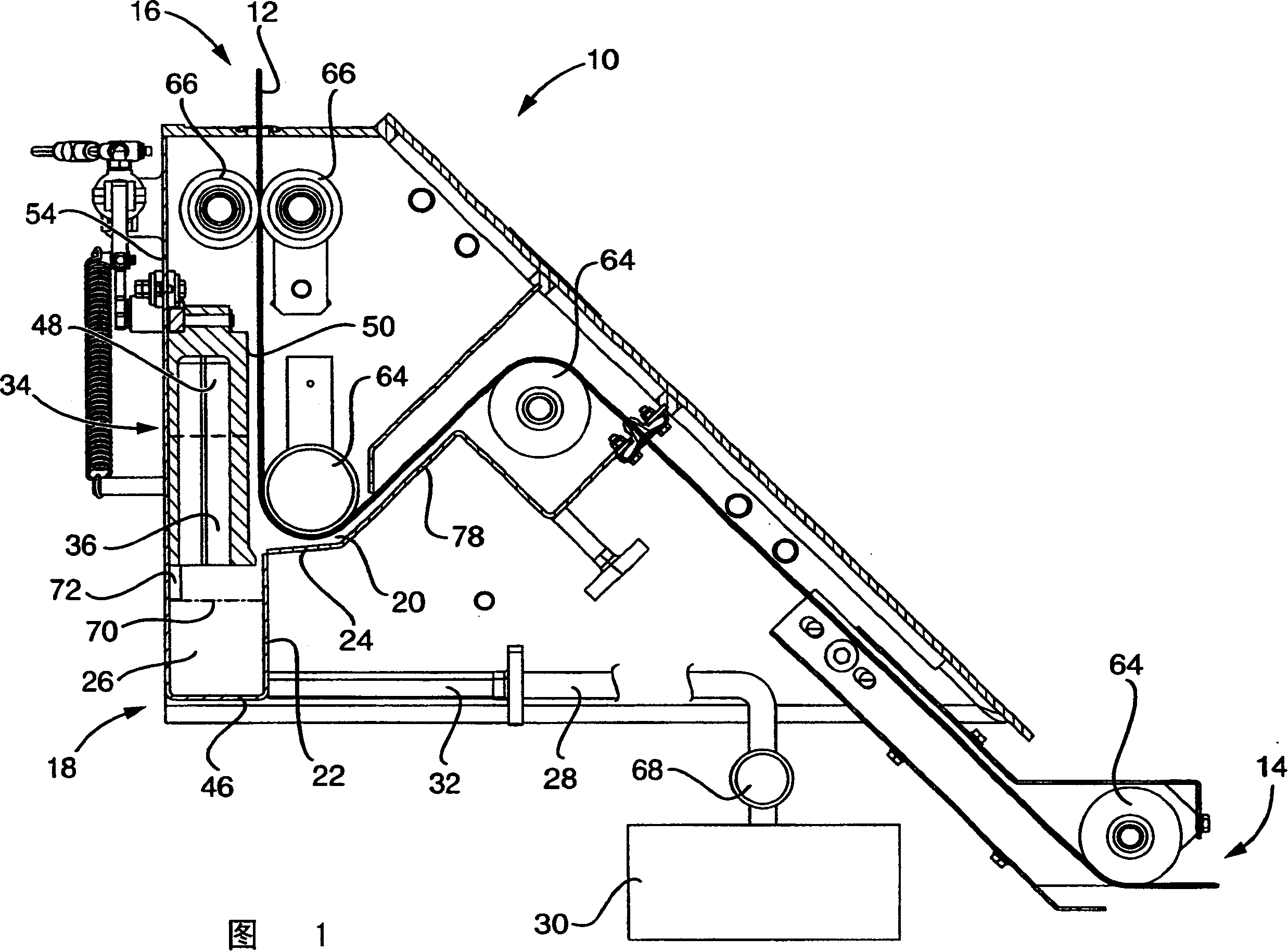

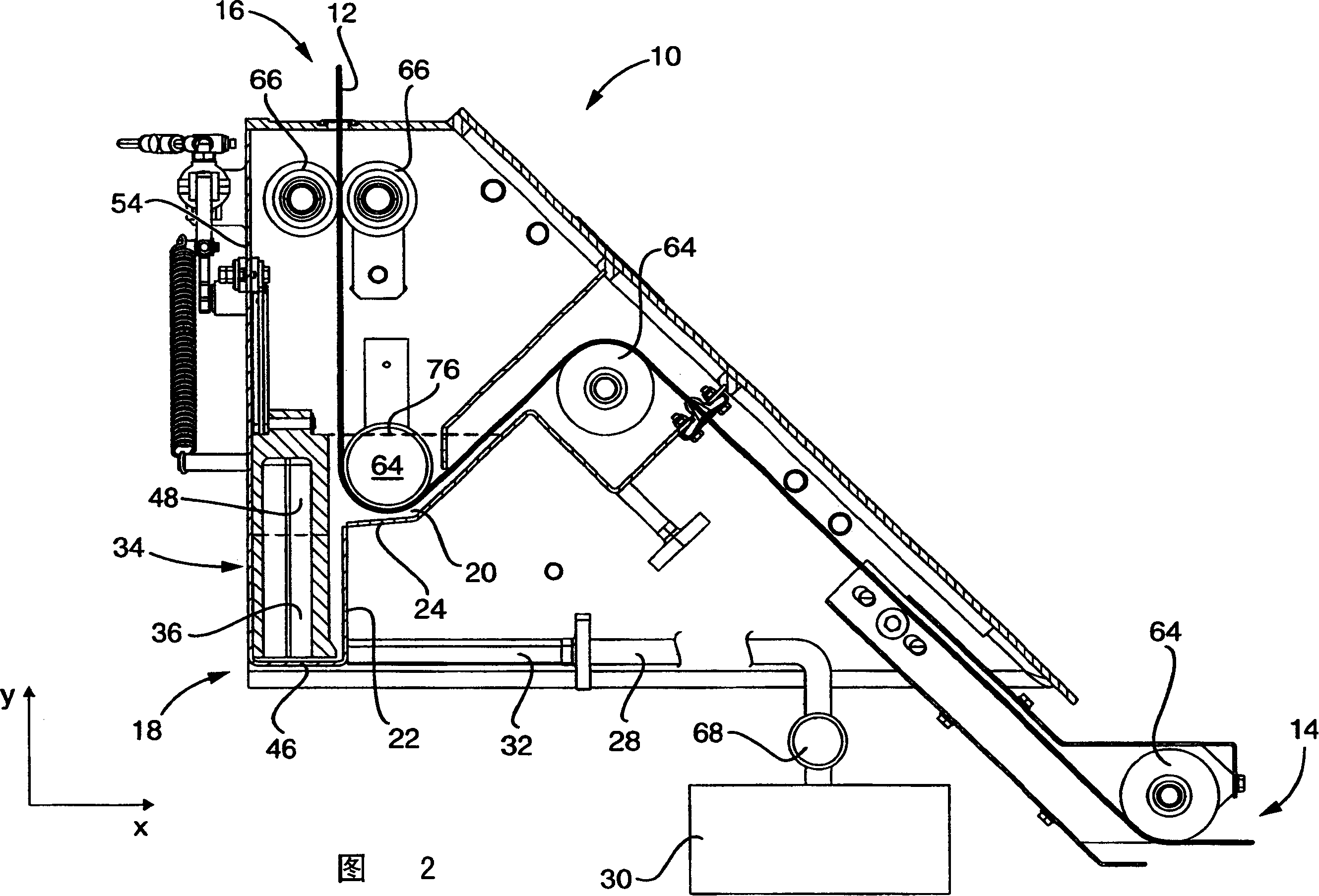

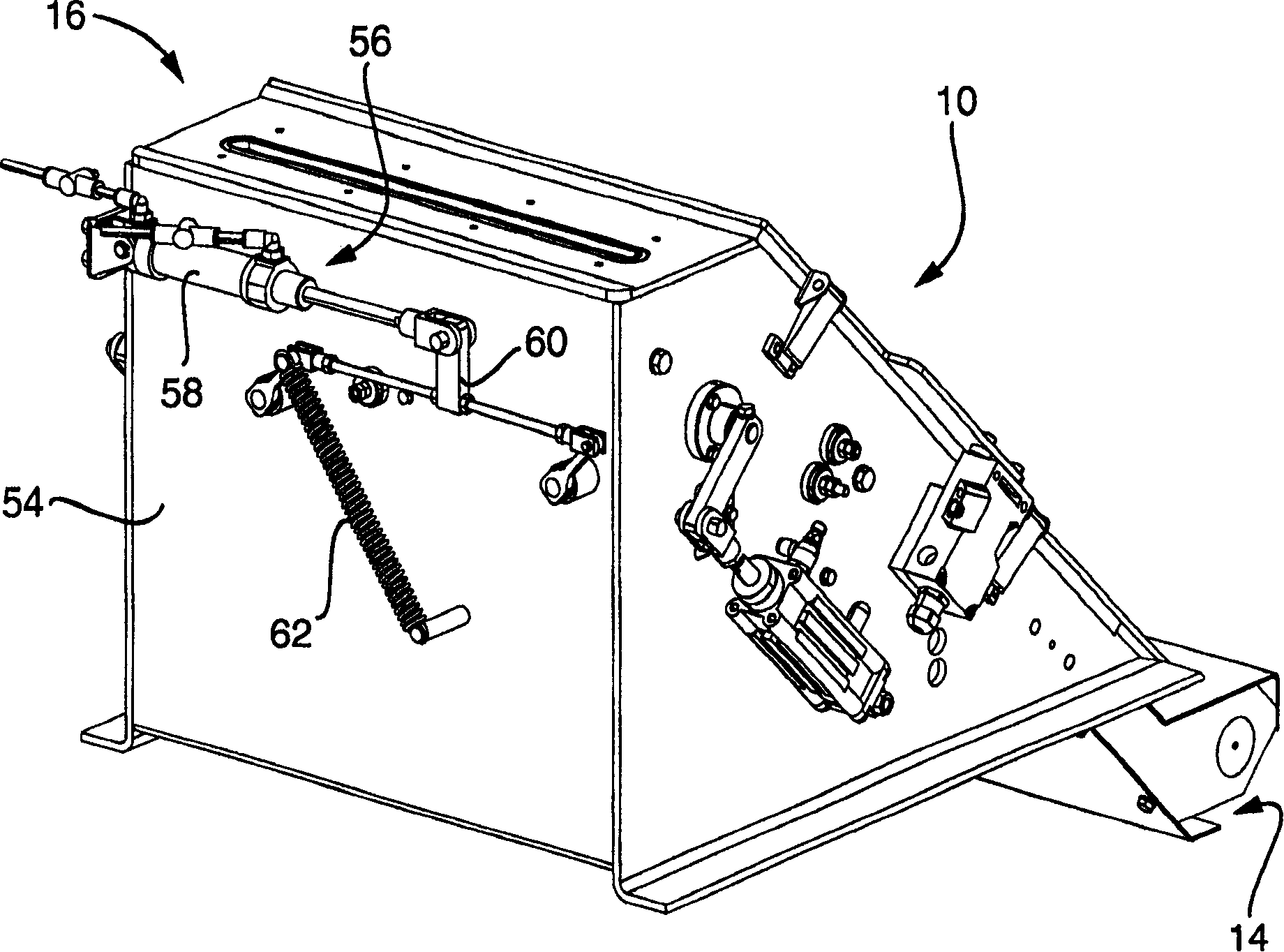

[0037] In Figures 1, 2 and 3 a sterilization device 10 is shown, through which a roll 12 of packaging material (shown only in Figures 1 and 2) passes, as described at the outset, before the tube is formed, filled and transversely sealed. to be sterilized. A roll 12 from a roll of packaging material (not shown) enters the apparatus 10 at an inlet 14 and exits the apparatus at an outlet 16 to enter a dryer (not shown).

[0038] Apparatus 10 includes a lower surge tank 18 and an upper bath 20 . The upper edge of the side wall 22 of the surge tank 18 is connected to the left edge of the bottom wall 24 of the bath 20, forming a direct transition between the surge tank and the bath. The bottom wall 24 of the bath 20 is not disposed perpendicular to the side wall 22 of the bath, but slopes gradually downward to the side wall 22 for reasons that will become apparent from the ensuing description. The interior 26 of the surge tank is substantially cuboid in shape. An inlet pipe 28 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com