Mechanical reduction gear and rim motor including the same

A gear reduction and gear technology, which is applied in the field of gear reduction mechanisms, can solve problems such as large volume, deflection and deformation of fixed columns, and bulky and complicated design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

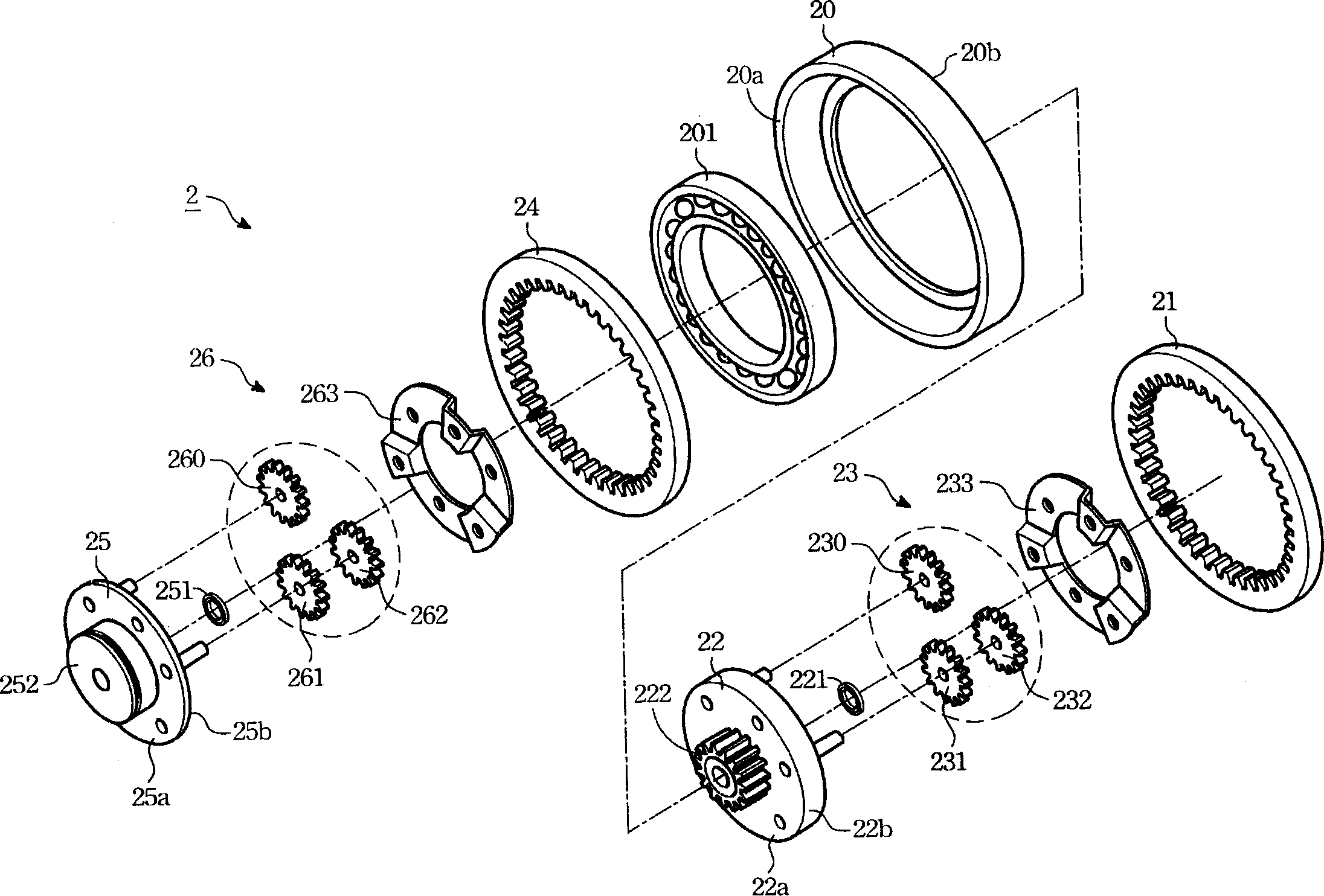

[0049] Such as image 3 Shown is an exploded view of a preferred embodiment of the gear reduction mechanism of the present invention.

[0050] As shown in the figure, the gear reduction mechanism 2 in this embodiment includes a housing frame 20, a second ring gear 21, a second bracket 22, a first gear assembly 23, a third ring gear 24, and a third bracket 25. The second gear assembly 26.

[0051] The shell frame 20 has a ring-shaped structure, and a first bearing 201 is arranged at the center thereof.

[0052] The second ring gear 21 is installed on one side 20b of the frame 20 . The tooth shape of its inner edge is positive tooth shape in this embodiment.

[0053] The second bracket 22 is disc-shaped, sleeved in the first bearing 201 , and can rotate in the first bearing 201 . In practice, various components (such as gears, ring gears, shafts of rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com