Drive method for backlight module of LCD device and its circuit

A liquid crystal display and backlight module technology, applied in static indicators, light sources, electric light sources, etc., can solve the problems of complicated circuits, reduced product reliability, easy to generate high heat, etc., to achieve high conversion efficiency, uniform brightness, and difficult heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further understand the structural features and other purposes of the present invention, the detailed description is as follows in conjunction with the accompanying drawings:

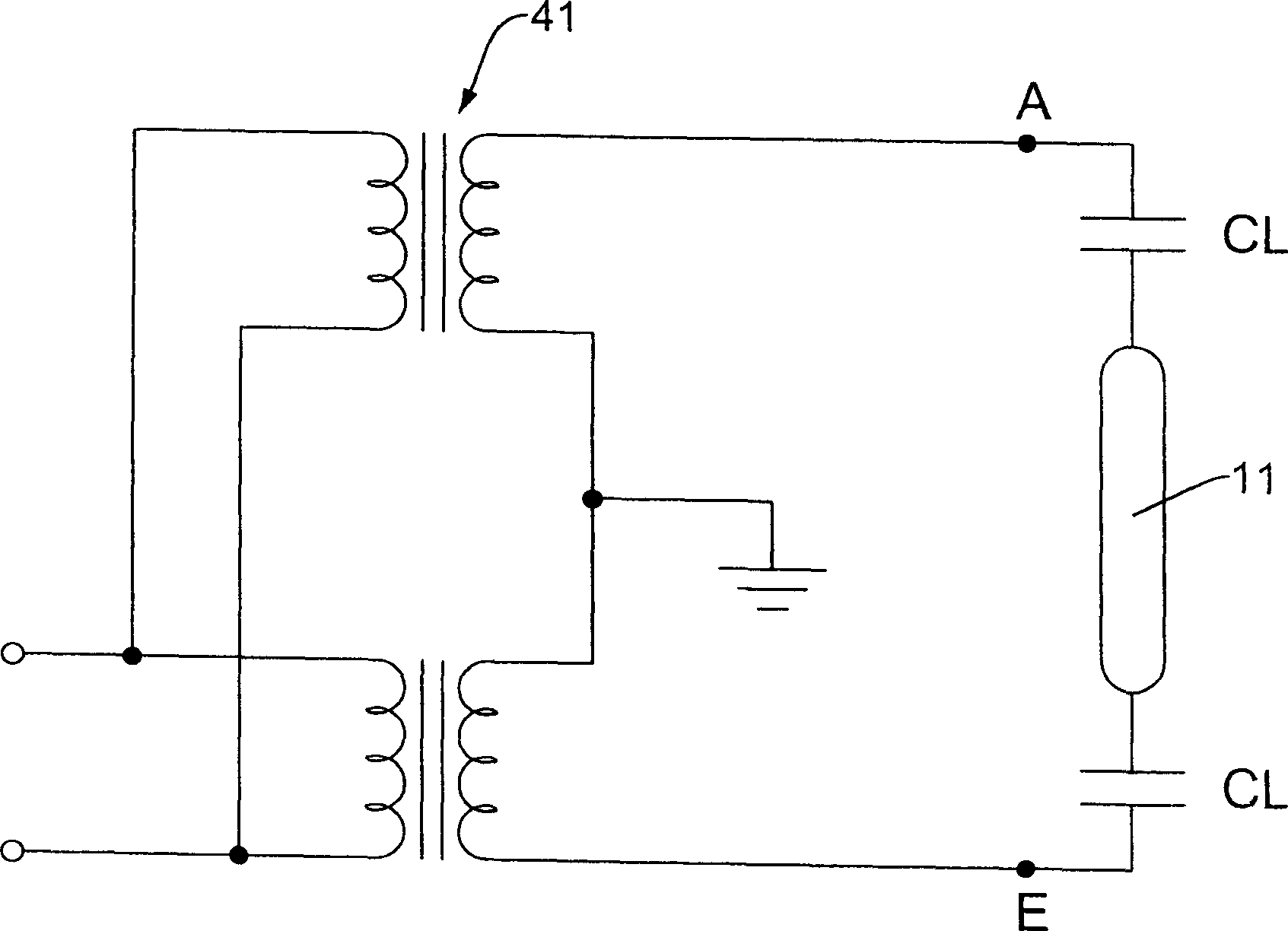

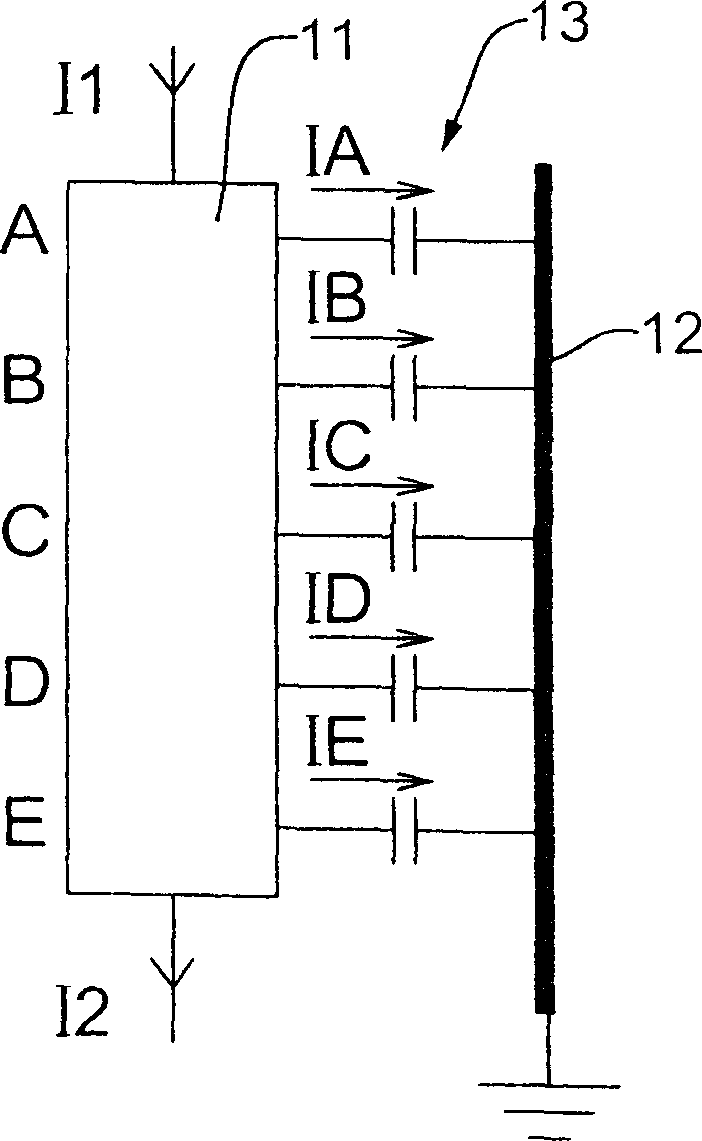

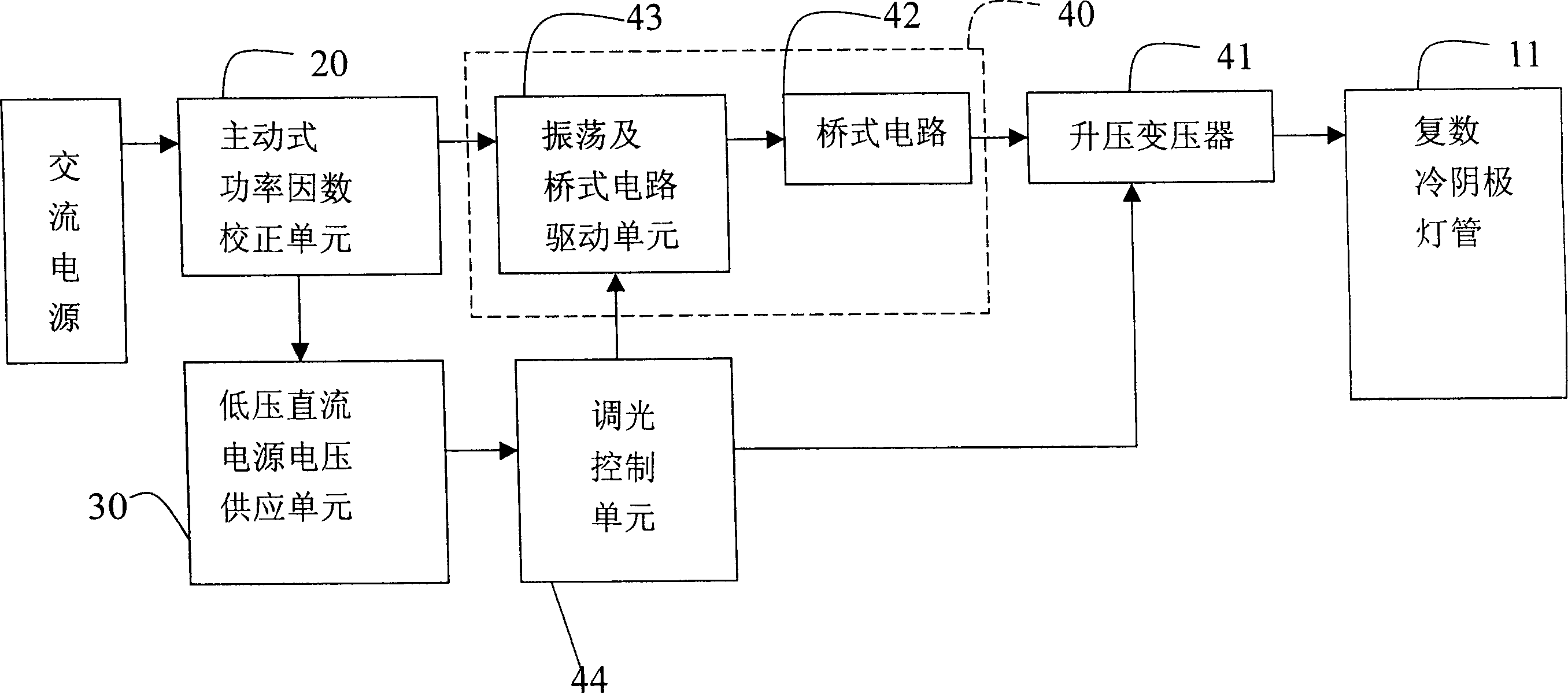

[0048] The invention is a driving circuit for driving a lamp tube to produce uniform luminance, and is mainly applied to a liquid crystal display. see first figure 1 As shown, the method of driving the lamp tube of the present invention is to connect the two ends of the lamp tube 11 to the high-frequency high-voltage power supply with a common ground, and to make the tube current more uniform and stable, a capacitor CL is connected in series at the two ends of the lamp tube 11 respectively. When connecting multiple groups of lamp tubes 11, connect a capacitor CL in series at both ends of each lamp tube 11, then connect the plurality of lamp tubes 11 in parallel, and connect the two nodes connected in parallel to two high-frequency high-voltage The power supply makes the two ends of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com