Special hydraulic press for crank axle bending and upsetting

A hydraulic press and bending technology, applied in the direction of upsetting presses, swaging presses, forging press drives, etc., can solve problems affecting the service life of crankshafts, metal forging streamline damage, and complex equipment structures, etc., to simplify forging Excellent craftsmanship, long service life, and the effect of solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

[0036] The power mode in this embodiment of the present invention is hydraulic mode, but not limited to hydraulic mode.

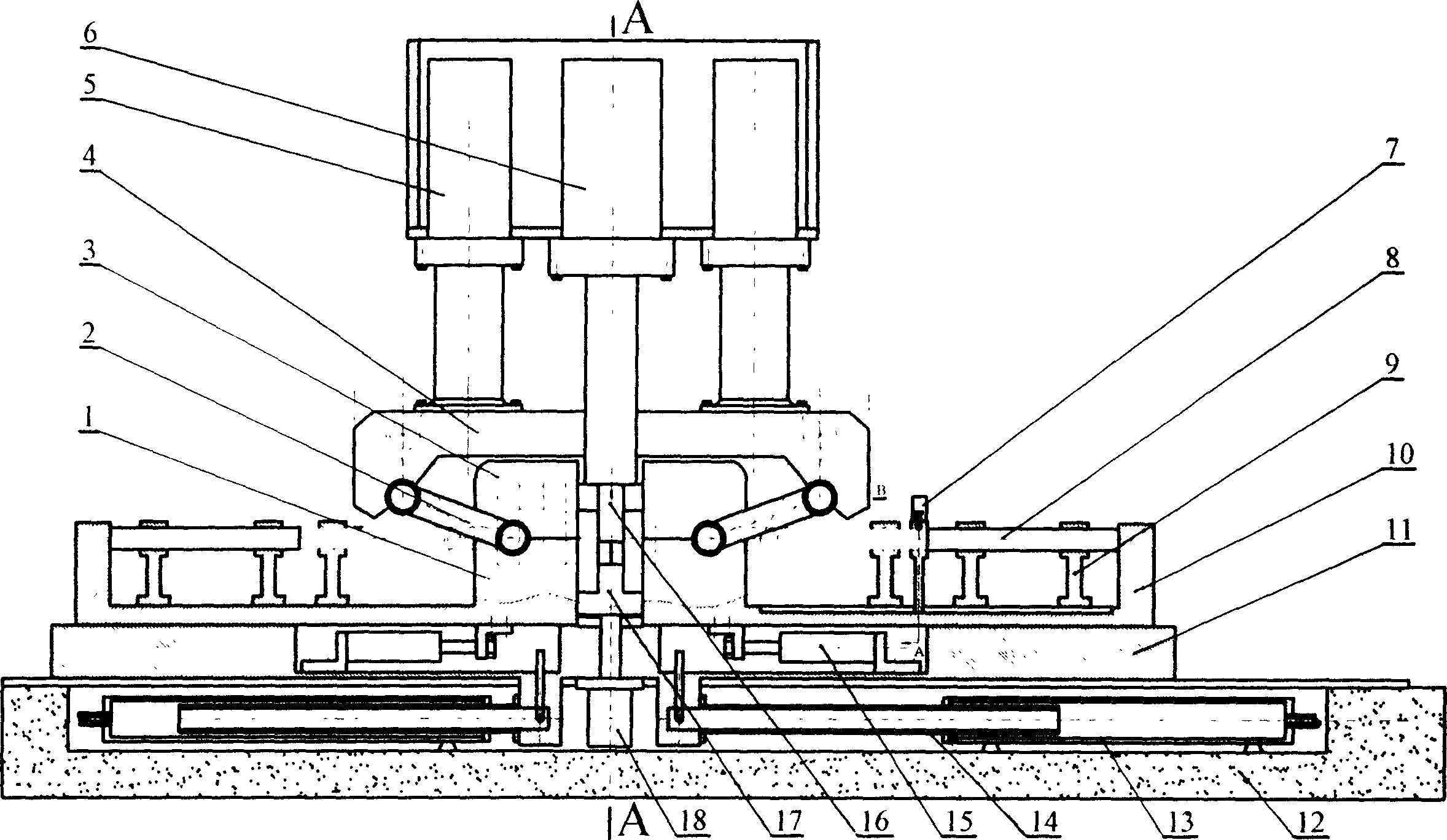

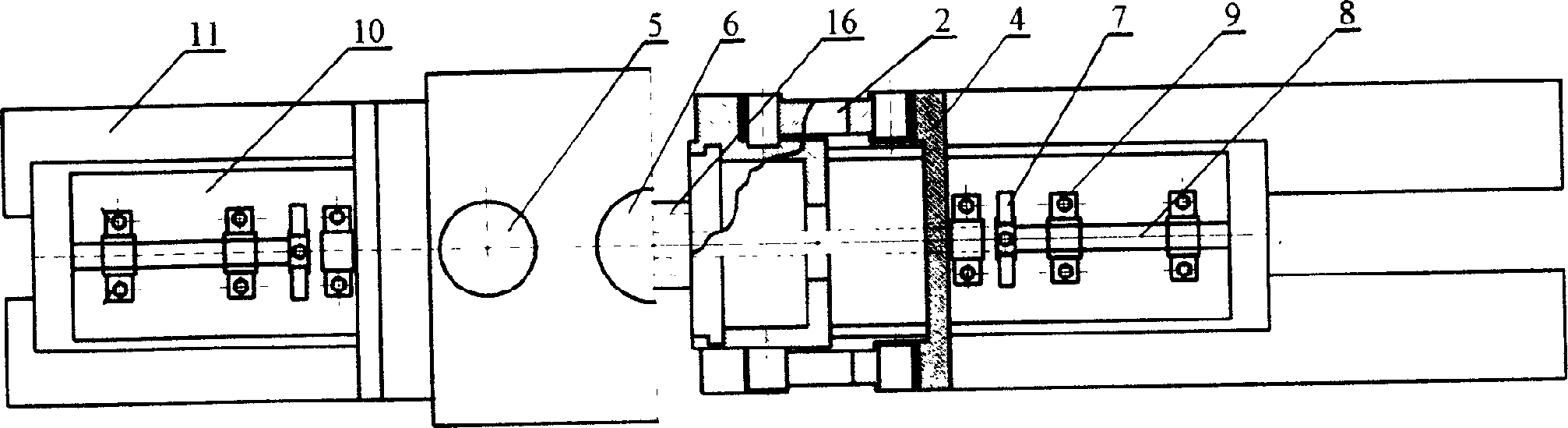

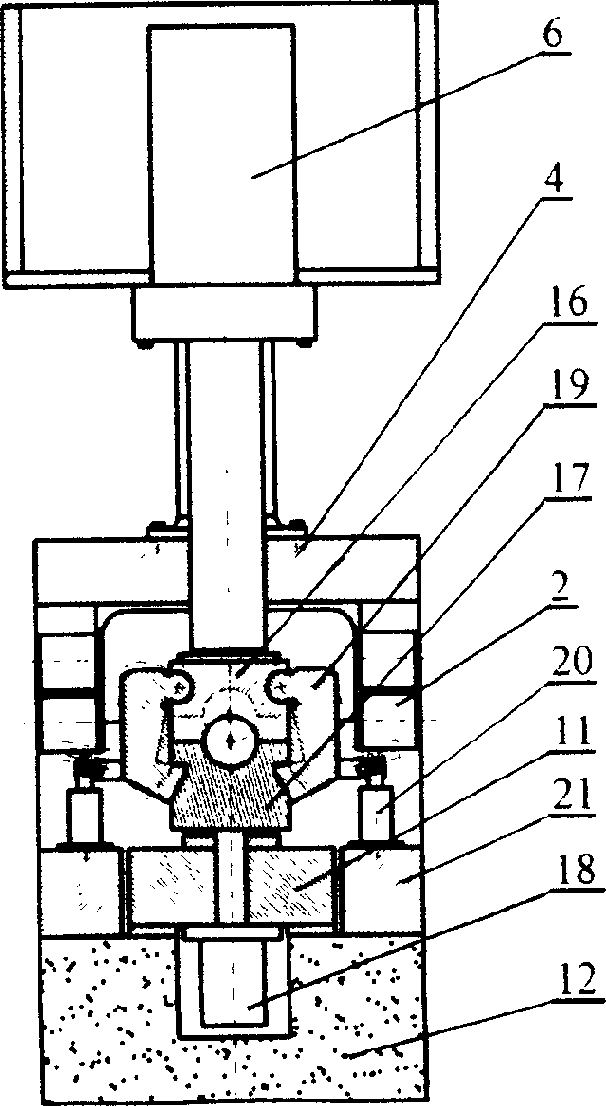

[0037] The special hydraulic press for crankshaft bending and upsetting has a main body consisting of an upper bending cylinder 6 and an upper bending die 16 connected with the plunger rod of the upper bending cylinder, upsetting cylinders 5 on both sides of the upper bending cylinder and a movable beam 4 connected with the plunger rod , the left and right upper mold boxes 3, the left and right lower mold boxes 1 on the movable workbench 11 (the extensions on both sides of the left and right lower mold boxes are labeled 10), the lower bending oil cylinder 18 and the lower bending cylinder 18 connected with its plunger rod Die 17, left and right lower die box return stroke cylinder 15, movable workbench moving cylinder 13 constitut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com