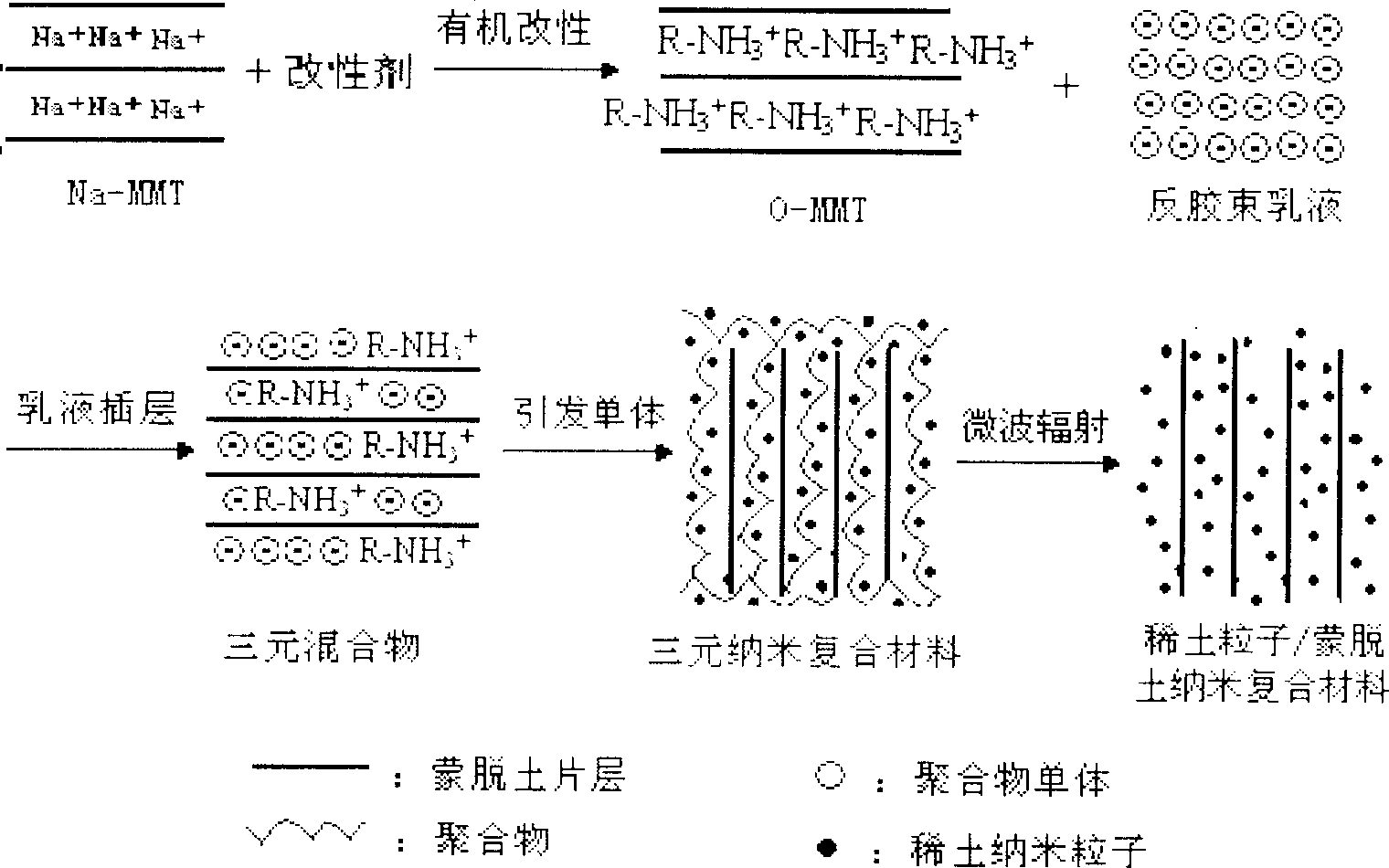

Rare earth particle and montmorillonite nano composite materials and process for preparing same

A nano-composite material and montmorillonite technology, which is applied in the field of nano-composite materials, can solve the problems that rare earth particles cannot be uniformly dispersed at the nanometer level, the inhomogeneity of rare earth particles, and affect the performance of composite materials. Compatibility problems, shortened preparation time, improved physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

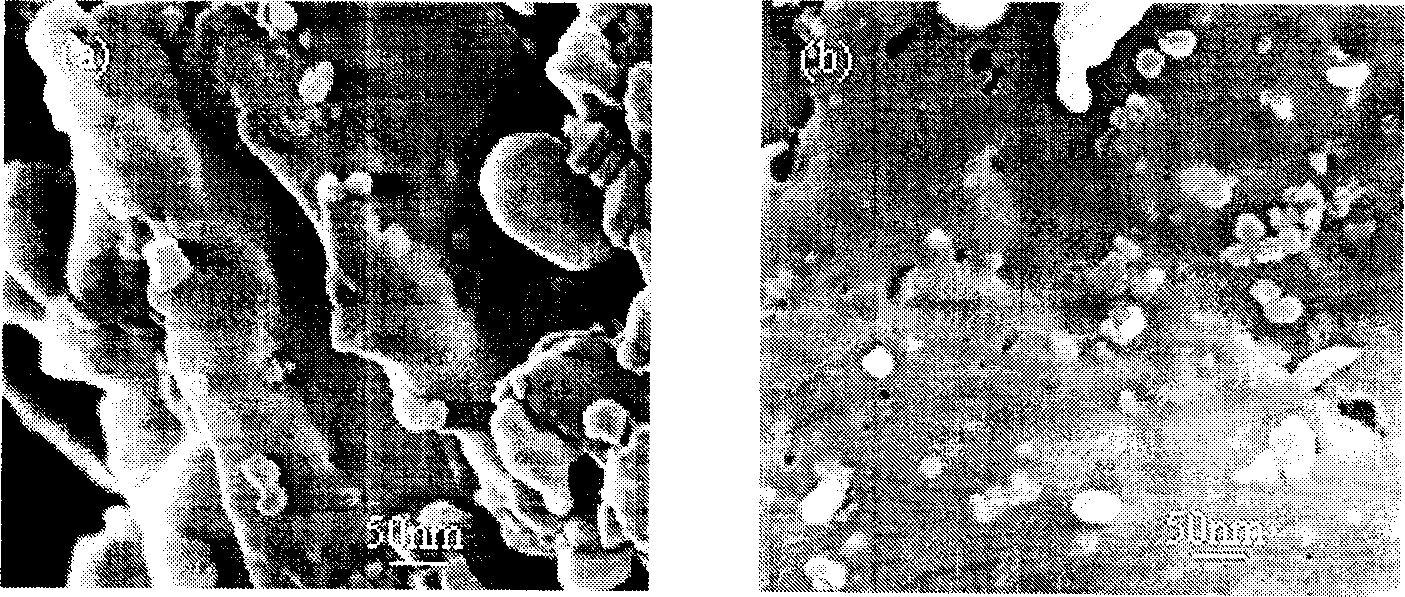

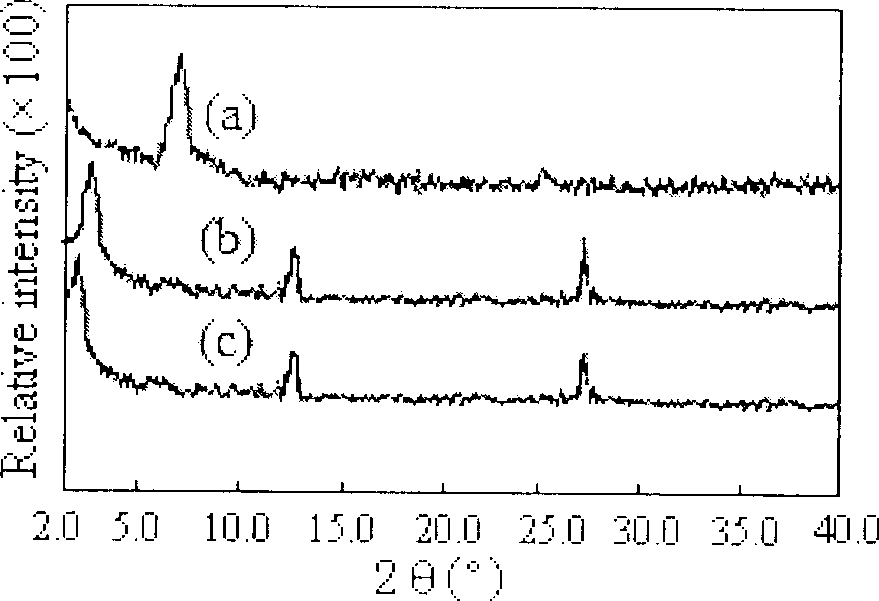

[0027] Example 1, 100 parts of aniline and 15 parts of sodium lauryl sulfate were added to 400 parts of water and stirred evenly; 20 parts of rare earth Nd 2 o 3 Soluble in hydrochloric acid to prepare 0.1mol / L NdCl 3 aqueous solution, and added to the above mixed solution, ultrasonically dispersed at room temperature for 30 minutes to form a reverse micellar emulsion. Put 1 weight of purified and organically modified montmorillonite in water, stir and heat in a water bath at a constant temperature of 40 to 60°C for 30 to 60 minutes, and then let it stand to form an aqueous dispersion of montmorillonite; 2 Under protection, the reverse micellar emulsion was added dropwise to the organic montmorillonite aqueous dispersion, the temperature was adjusted to 60°C, and the intercalation was dispersed for 2 hours with magnetic stirring. Then lower the temperature, move the reactant to an ice-water bath at about 2°C, and add 100 parts of ammonium sulfate initiator dropwise to initia...

Embodiment 2

[0028] Example 2, 100 parts of methyl methacrylate and 18 parts of sodium stearate were added to 500 parts of chloroform and stirred evenly; 15 parts of rare earth Nd 2 o 3 Soluble in hydrochloric acid to prepare 0.1mol / L EuCl 3 aqueous solution, and added to the above mixed solution, ultrasonically dispersed at room temperature for 35 minutes to form a reverse micellar emulsion; put 6 parts of purified and organically modified montmorillonite in water, and place it in a water bath with a constant temperature of 40-60°C Stir and heat for 30 to 60 minutes and then stand still to form a montmorillonite water dispersion; then in N 2 Add the reverse micellar emulsion dropwise to the aqueous dispersion of organic montmorillonite under protection, adjust the temperature to 65°C, disperse the intercalation with magnetic stirring for 2.5 hours, and then add 0.001 part of azobisisobutyronitrile to make the polymer monomer Initiate polymerization, add 0.3mol / L NaOH solution after 18 h...

Embodiment 3

[0029] Example 3, 100 parts of methyl acrylate and 20 parts of stearic acid were added to 700 parts of ethanol and stirred evenly; 10 parts of rare earth La 2 o 3 Soluble in hydrochloric acid to prepare 0.1mol / L LaCl 3 aqueous solution, and added to the above mixed solution, and ultrasonically dispersed at room temperature for 40 minutes to form a reverse micellar emulsion; 12 parts of purified and organically modified montmorillonite were placed in water and placed in a water bath at a constant temperature of 40-60°C Stirring and heating in medium for 30-60min and then standing still to form montmorillonite aqueous dispersion; then in N 2 Add the reverse micellar emulsion dropwise to the organic montmorillonite aqueous dispersion under protection, adjust the temperature to 70°C, and disperse the intercalation with magnetic stirring for 3 hours, then add 1 part of azobisisobutyronitrile as an initiator to make the polymerization After reacting for 20 hours, add 0.3mol / L NaOH...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap