Technical porcelain and household porcelain and firing method therefor

A technology for arts and crafts, daily-use porcelain, applied in applications, clay products, household utensils, etc., can solve the problems of high price, complicated firing process, difficult to control firing system, etc., to achieve both practicability and viewing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

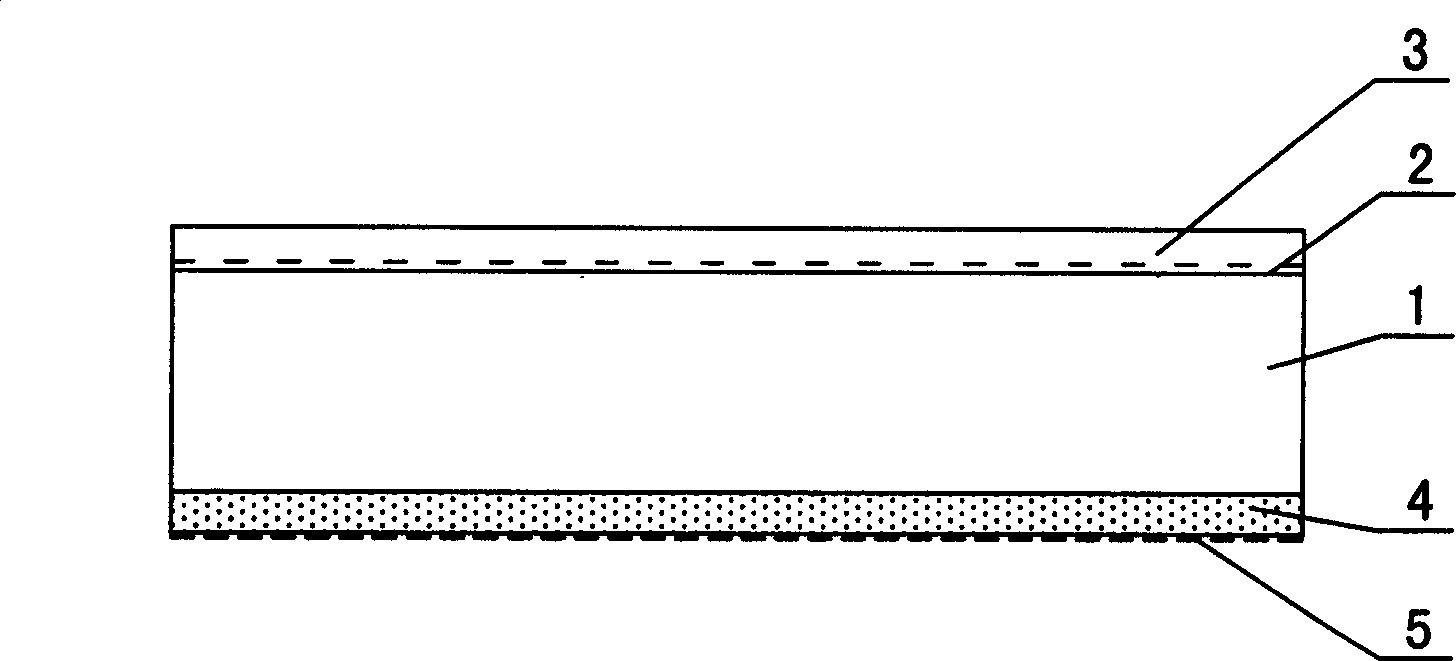

[0020] refer to figure 1 , the present embodiment includes a porcelain body 1, a multicolored pattern 2 is arranged on one side of the porcelain body, a transparent glaze 3 is covered on the entire surface, the other side of the porcelain body is covered with a red glaze 4, and an on-glaze color 5 is arranged on the surface of the red glaze.

[0021] Processing and firing methods: (1) making blanks and bisque firing porcelain blanks; (2) drawing underglaze colorful patterns or pasting underglaze colorful flower paper on one side of the fired porcelain blanks; Apply transparent glaze on one side, and then fire at high temperature (1350°C-1380°C); (4) apply red glaze on the other side of the porcelain body by dipping or spraying glaze, and then fire at 1150°C-1200°C; (5) Then paint on the red glaze and draw gold on the glaze, then bake flowers at 760°C-780°C, cool, and it's done.

Embodiment 2

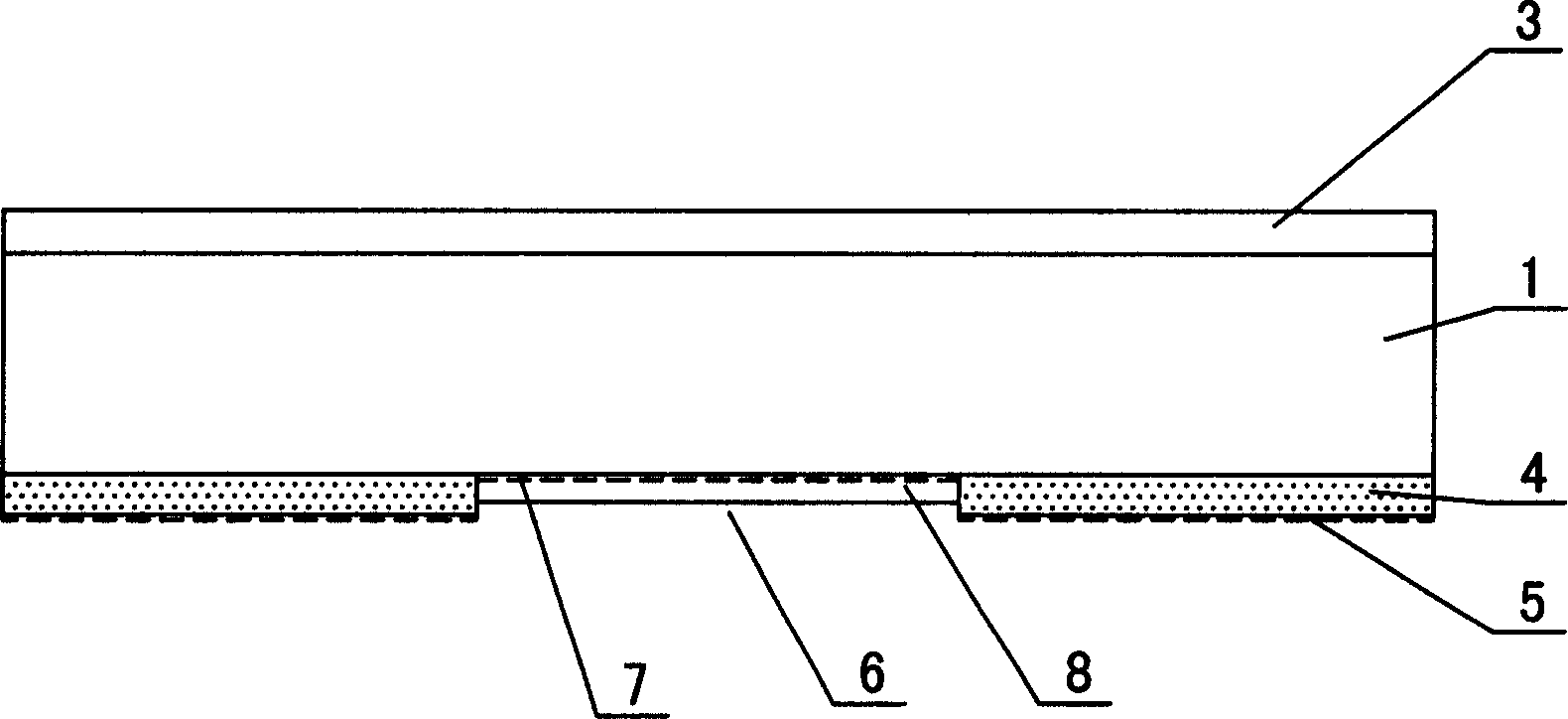

[0023] One side of the porcelain blank 1 is covered with a red glaze 4 that meets the design requirements "window" 6, and the surface of the porcelain blank 1 at the "window" 6 has a multicolored pattern 7, and the multicolored pattern 7 is covered with a transparent glaze 8, and the surface of the red glaze 4 has Overglaze color 5; the other side of porcelain blank 1 has transparent glaze 3.

[0024] Processing and firing method: when red glaze 4 is applied to one side of porcelain body 1, the "window" 6 used for making underglaze color without applying red glaze is reserved according to design requirements; the firing temperature of red glaze is 750°C-900°C. All the other are identical with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap