Honeycomb charcoal with ignition space

A technology of honeycomb charcoal and fire holes, which is applied in the direction of ignition materials, petroleum industry, etc., can solve the problems of difficult fire of honeycomb charcoal and high consumption of combustion resources, and achieves the effects of favorable promotion, low production cost and easy mold opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

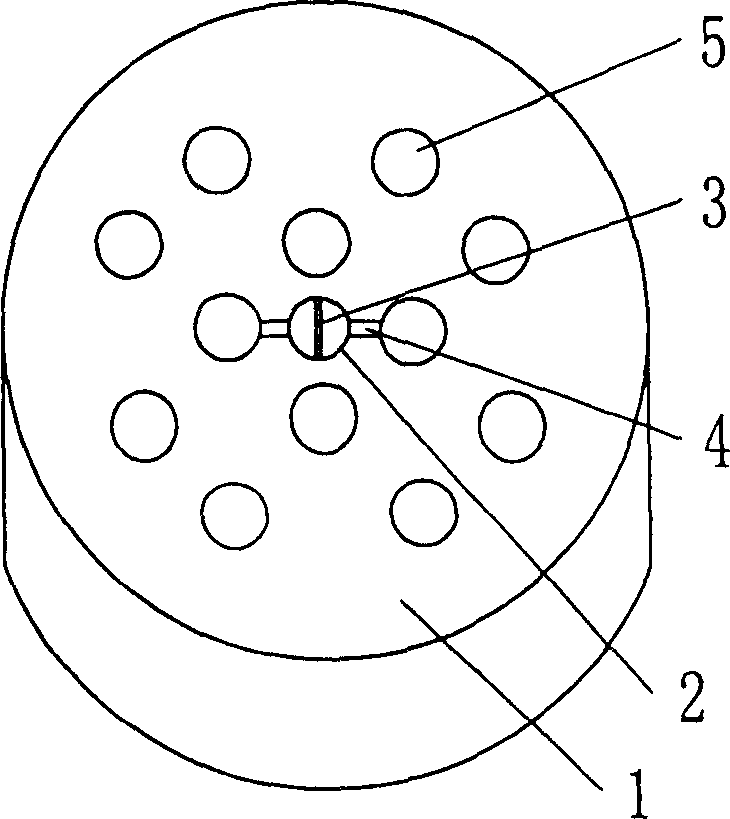

[0015] Embodiment 1: refer to figure 1 , This fire-igniting honeycomb charcoal includes a main body 1, and the main body 1 is formed by mixing and pressing charcoal powder (machine-made charcoal, charcoal, etc.), spice powder and binding agent, etc., so that it is easy to ignite. The main body 1 is provided with the continuous pores 5 corresponding to common briquettes, which are in a shape similar to common briquettes, i.e. cylindrical (also in other shapes such as cuboids), with a circle diameter of 7-10 centimeters and a height of 2-3.5 centimeters. The quantity of pore 5 can be consistent with the pore of honeycomb briquette that is 12 holes, also can be 4 holes, 8 holes, as long as the pore 5 on it corresponds to the pore of briquette. Stomach 5 is easy to ignite honeycomb coal. The central part of the main body 1 is provided with a through circular ignition hole 2, an ignition point 3 is arranged on the ignition hole 2, and a thin-walled crosspiece is arranged in the ig...

Embodiment 2

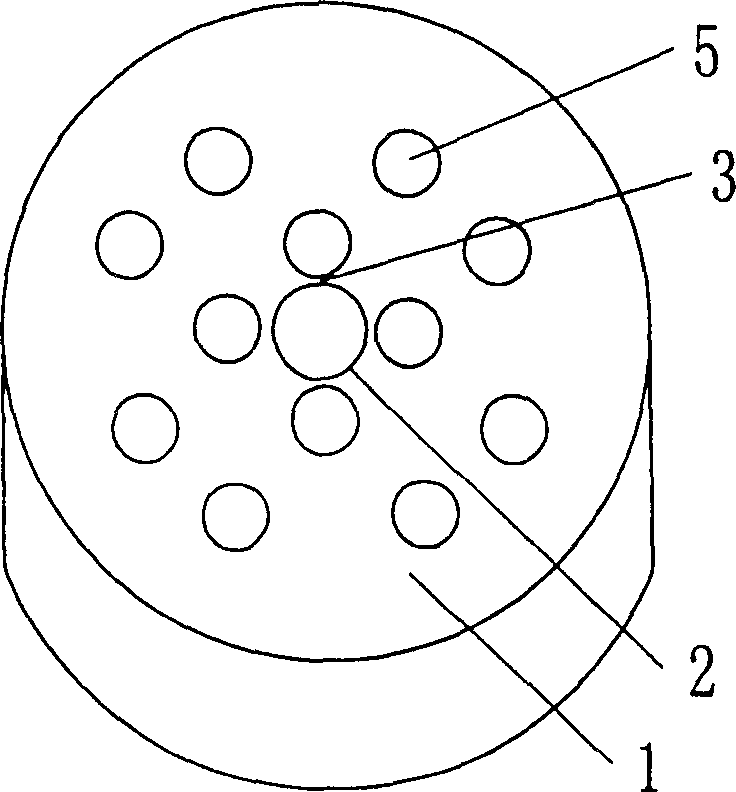

[0020] Embodiment 2: refer to figure 2 , the difference from Embodiment 1 is that the hole wall of the ignition hole 2 is a thin-walled shape that is easy to ignite, and the ignition point 3 is the thin wall. The interval between the ignition hole 2 and the adjacent air hole 5 is relatively small, forming a thinner hole wall, which is the ignition point 3, which can be easily ignited at this place during ignition.

Embodiment 3

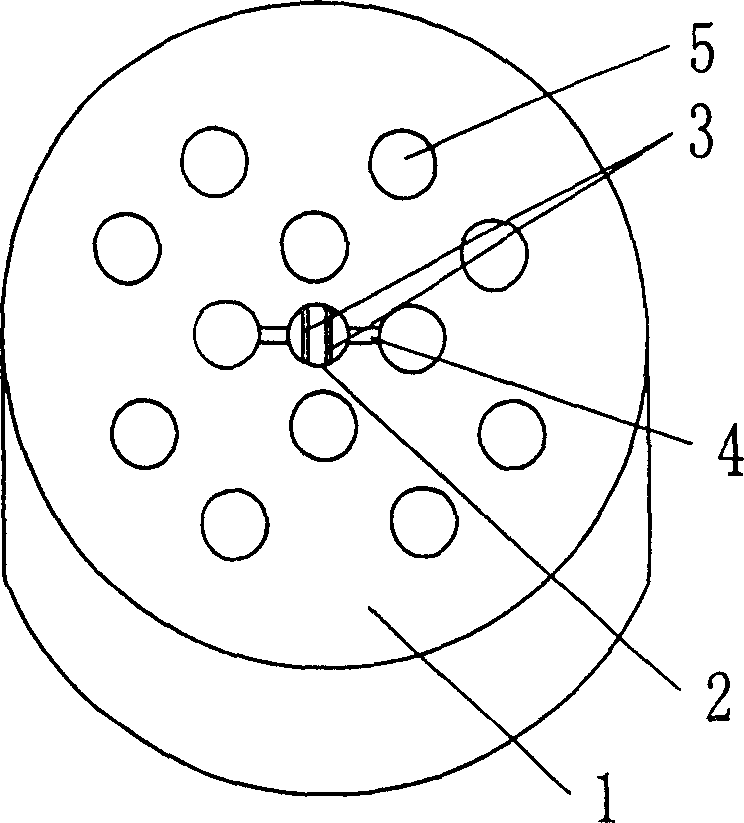

[0021] Embodiment 3: refer to image 3 , The difference from Example 1 is that two thin-walled crosspieces are provided in the ignition hole 2, which is easier to ignite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com