Pattern correction device, pattern correction method and pattern correction assembly

A pattern and component technology, which is applied in the field of pattern correction components, can solve problems such as time-consuming, achieve the effect of shortening time, shortening standby time, and realizing the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0161] Implementation form 1:

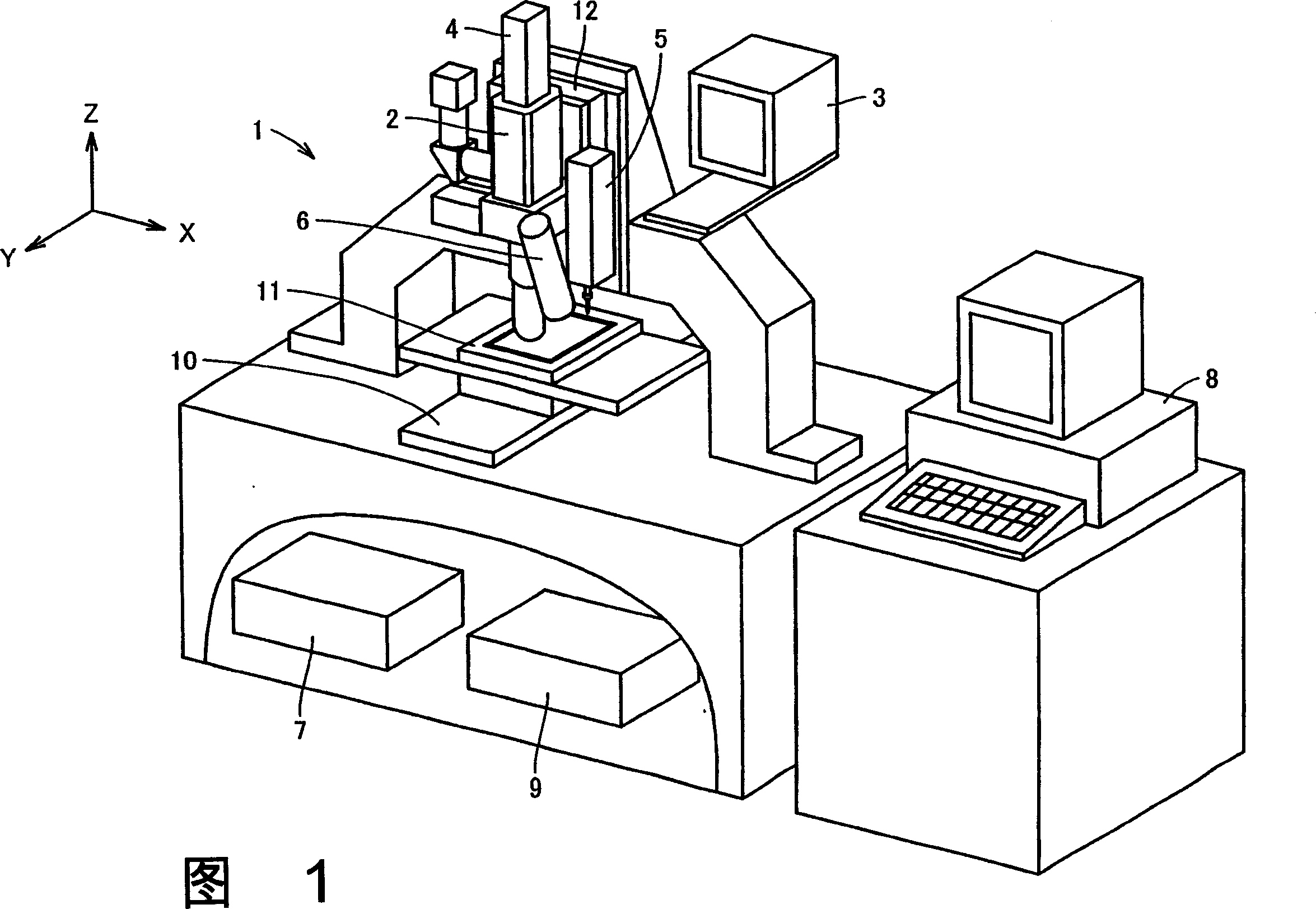

[0162] Fig. 1 is a diagram showing the overall structure of a pattern correction device according to Embodiment 1 of the present invention. In FIG. 1 , a pattern correction device 1 includes: an observation optical system 2 for observing the surface of a substrate; a monitor 3 for reflecting the observed image; and a cutting laser unit for irradiating laser light to the substrate through the observation optical system 2 to cut off unnecessary parts. 4. The coating mechanism part 5 that makes the correction liquid adhere to the tip of the coating needle to coat the defect part of the substrate; the substrate heating part 6 that heats the correction liquid applied to the defect part; image processing for identifying the defect part 7; a host computer 8 for controlling the entire device; and a control computer 9 for controlling the operation of the mechanism part of the device. In addition, there are also provided: an XY stage 10 for moving a subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com