Rear suspension for turbojet engine

A technology on jet engines and brackets, which is applied in the directions of power units, jet power units, and aircraft parts on aircraft to achieve the effect of simplifying geometric shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

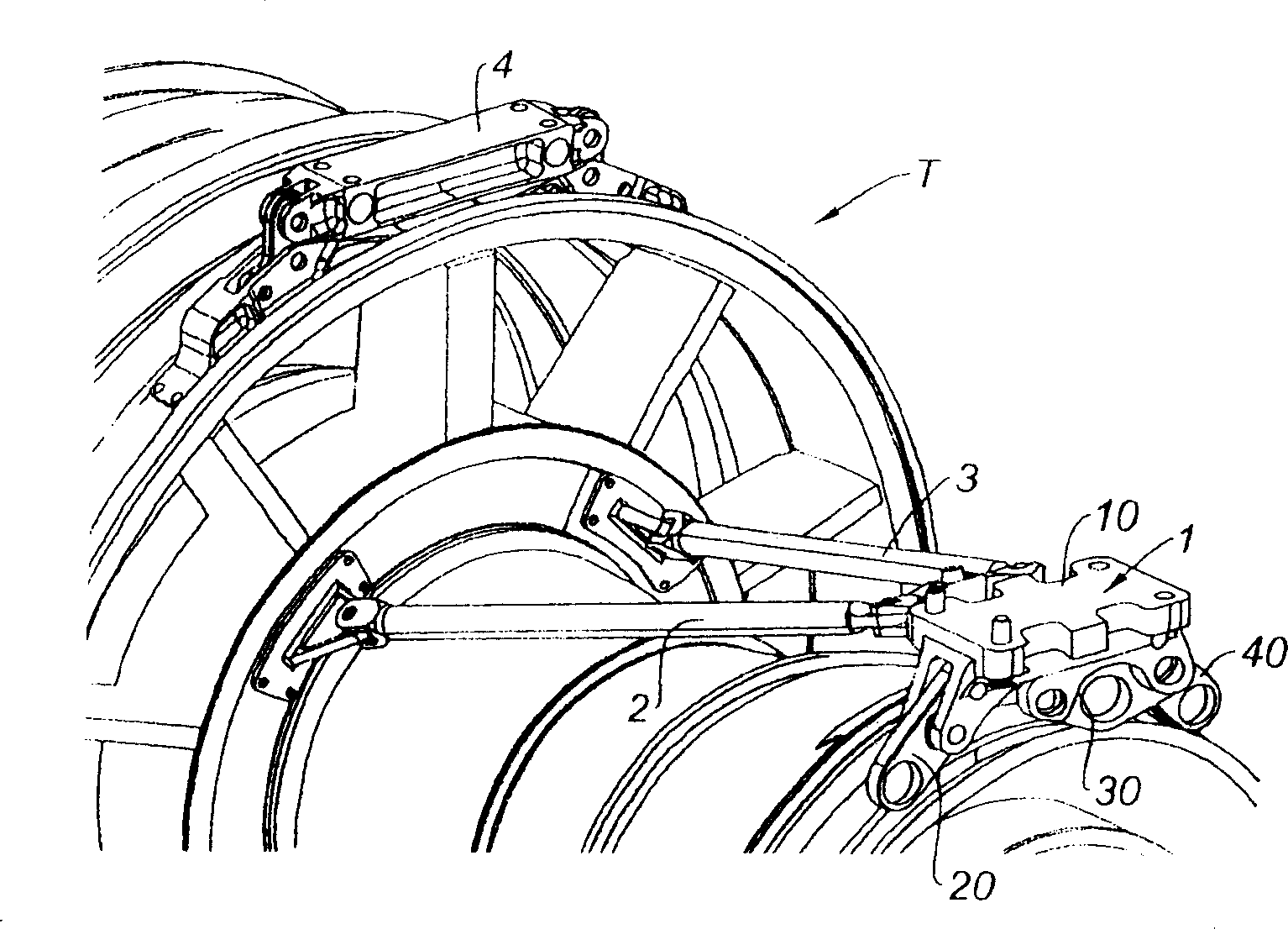

[0021] figure 1 Is a rear three-quarter view of a jet engine T equipped with a connection to an aircraft mount (not shown). In particular, the engine may be connected to an aircraft wing. According to this suspension method, the engine comprises a connection device 4 in front of the engine, which is fastened to the intermediate fan case. It also includes connection means 1 at the rear, which is connected to the main exhaust casing. The thrust is absorbed by two rods 2 and 3, arranged longitudinally on either side of the engine shaft and connected at their ends, on the one hand to the hub of the fan housing and on the other hand to the rear Connectors.

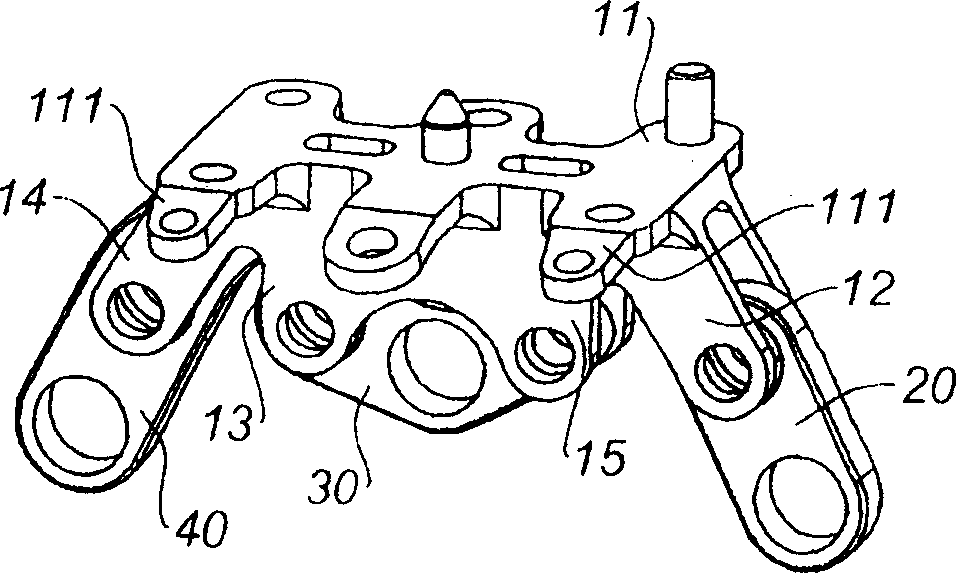

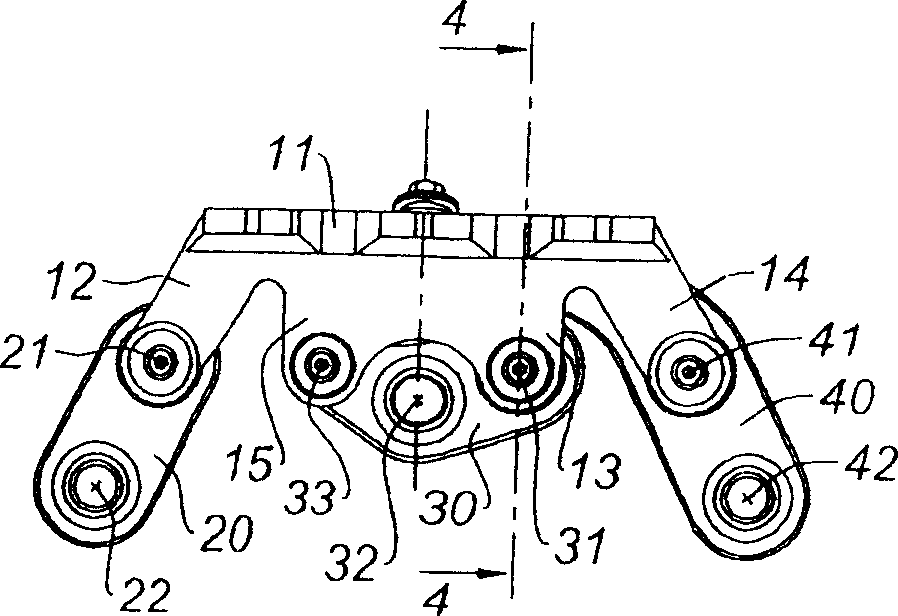

[0022] The following description refers to the rear connection 1 . From figure 2 and image 3 It can be seen that the connection comprises a beam 10 for fastening to a bracket or pylon of the aircraft, and three connection parts 20, 30, 40 connecting this beam 10 to a clevis fastened to the engine case . These clevis a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com