Method and device for drying fiber material

A fiber material and drying technology, applied in the direction of drying gas arrangement, combustion method, heating device, etc., can solve the problems of adjusting the temperature lag of the process gas flow and reducing the efficiency of the drying device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

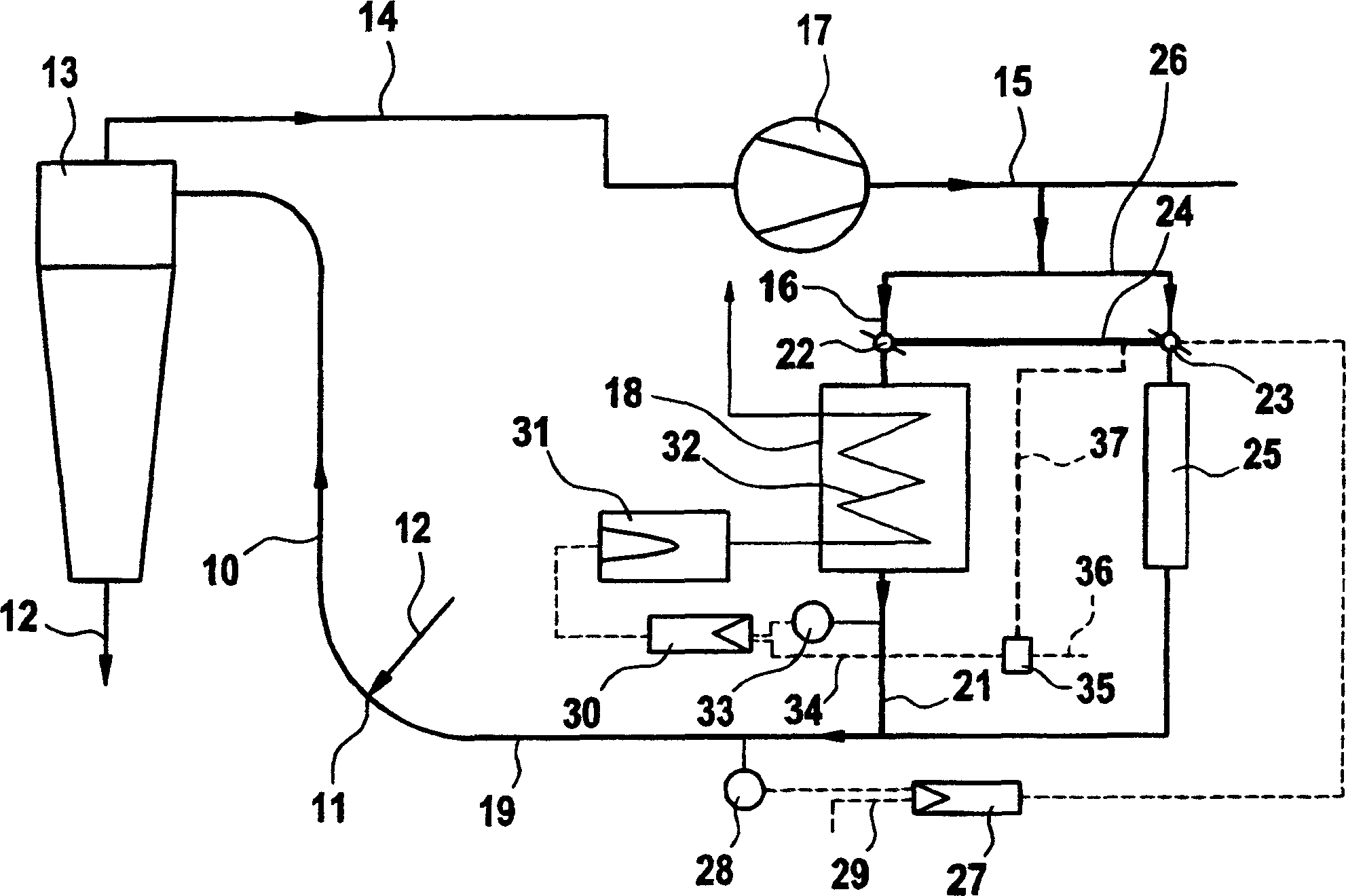

[0010] exist figure 1 This drying apparatus shown in includes a tubular airflow dryer with or without a steam section, in particular hot air or hot steam (superheated steam) at a temperature between 130°C and 150°C flowing through the hot process gas 10. The airflow dryer 10 is a part of the pipeline through which the process gas flows in the direction of the arrow. The air dryer 10 comprises a product inlet 11 for the tobacco 12 to be dried. The tobacco 12 is conveyed by the process gas flow and in the process is dried in the air dryer 10 . The dried tobacco is separated by a separator 13 from the hot air which is conveyed by a compressor 17 to a heat exchanger 18 through pipes 14-16. Through the heat exchanger 18, the process gas is heated to the required drying temperature to recover the heat extracted by the drying process. For this purpose, heat is transferred to the above-mentioned heat exchanger 18 by means of a combustion-supporting gas flow 32 generated by the bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com