Structure of package using coupling and its forming method

A packaging structure and bump technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of lower product yield, open circuit, contact short circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

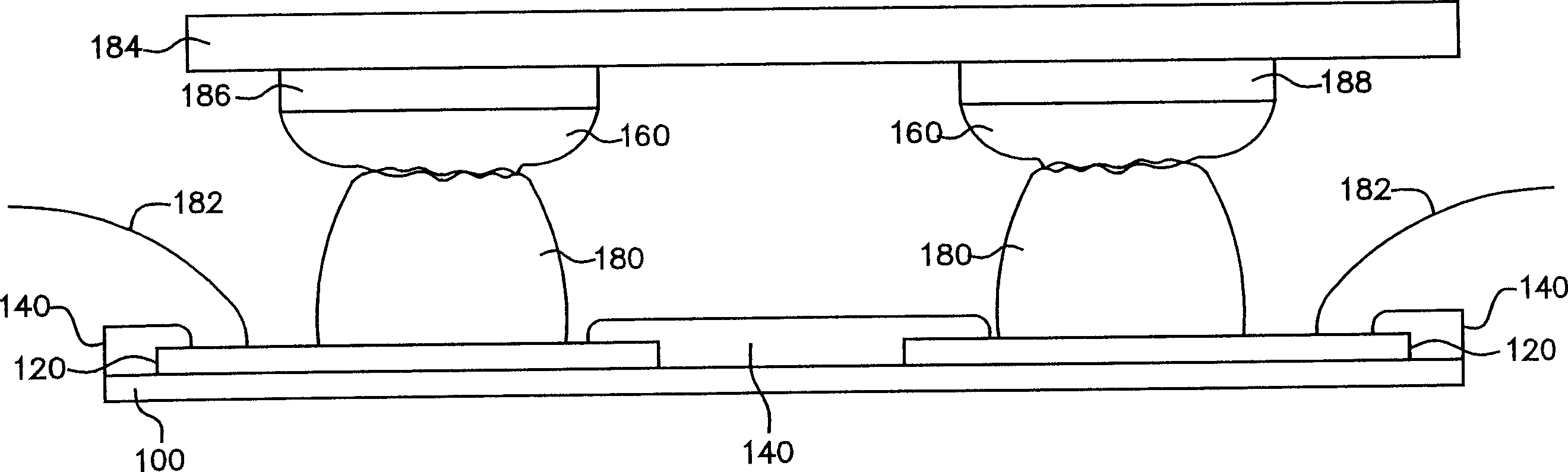

[0022] A preferred embodiment of the package structure and its forming method of the present invention is described in detail as follows.

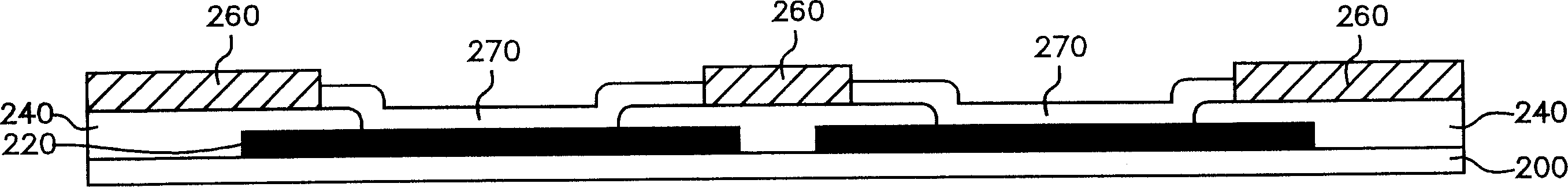

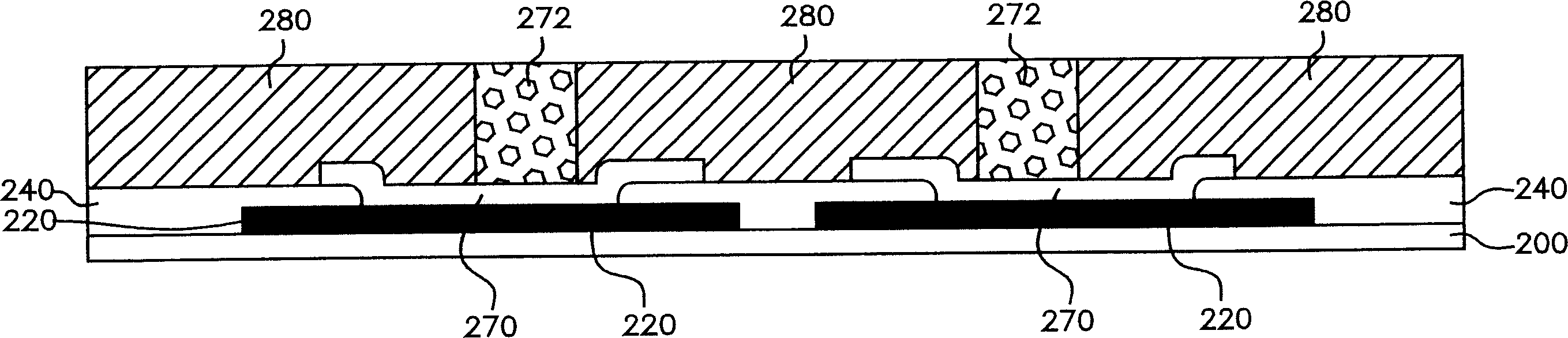

[0023] Figures 2A to 2D It is a schematic cross-sectional view of the forming process of the packaging structure of the present invention. First please refer to Figure 2A , sequentially forming a pad 220 and a protection layer 240 on a substrate 200 , the protection layer 240 is formed around the pad 220 to protect components on the substrate 200 . Wherein, the material forming the pad 220 is metal, preferably an aluminum pad. Next, a mask layer 260 is formed on the protective layer 240 by using a lithography process, and the contact pad 220 is exposed to define the formation position of the first bump 270, and then an electroplating process is performed to form the first bump 270 in the defined position. A first bump 270 with a height of about 2-3 μm. The first bump 270 will completely cover the pad 220 for protecting the pad 220 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com