Flexible display substrate, display panel, display device and manufacturing method

A flexible display and manufacturing method technology, applied in the directions of identification devices, final product manufacturing, climate sustainability, etc., can solve the problems of flexible display substrates such as subsidence, breakage, or contact with driver ICs, product short circuits, etc., to improve the binding process Yield rate, weaken further deformation, effect of guarantee binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

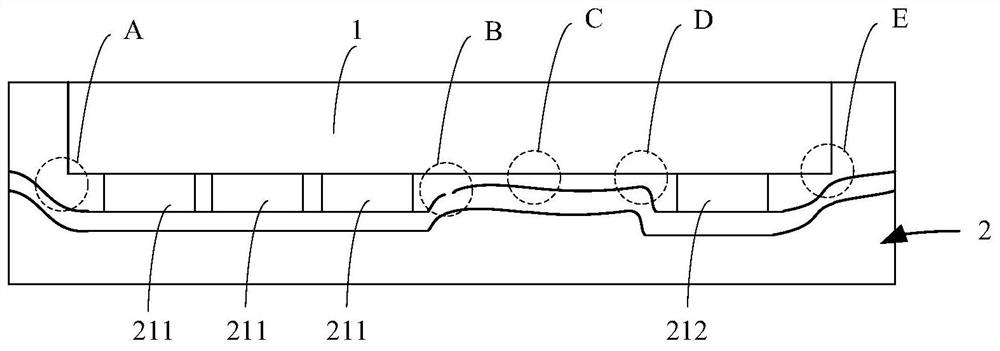

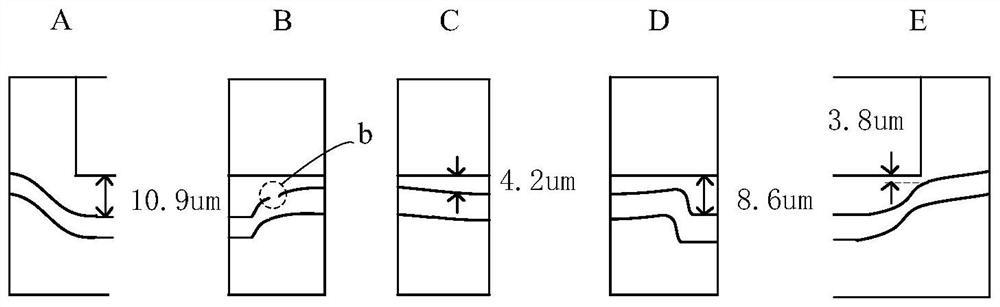

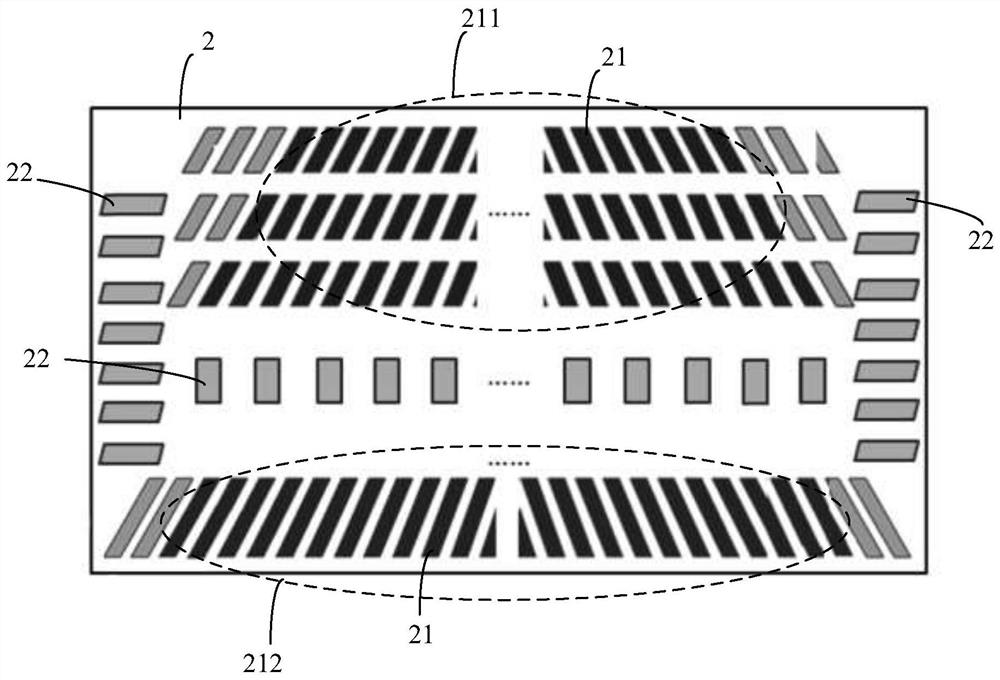

[0046] Increasing the screen-to-body ratio (that is, the area ratio of the display screen in the display device) is a development trend of OLED display devices at present. At present, an effective way to increase the screen ratio is to bind the driver chip on the flexible display substrate through the COP process. The COP process makes full use of the foldability of the flexible display substrate, and folds the part of the flexible display substrate with the driver chip to the back of the display screen, thereby increasing the screen-to-body ratio. However, since the rigidity of the flexible display substrate is not high, it is prone to deformation during the binding process, resulting in defective defects of the display device.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com