Forced circulating type solar stove employing condenser to guide sunlight and high-temperature phase-change material to store solar energy

A high-temperature phase change and forced circulation technology, applied in the field of solar concentrating and solar thermal utilization, can solve the problem of low operating temperature, and achieve the effects of high heat storage efficiency, good energy consumption environment and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

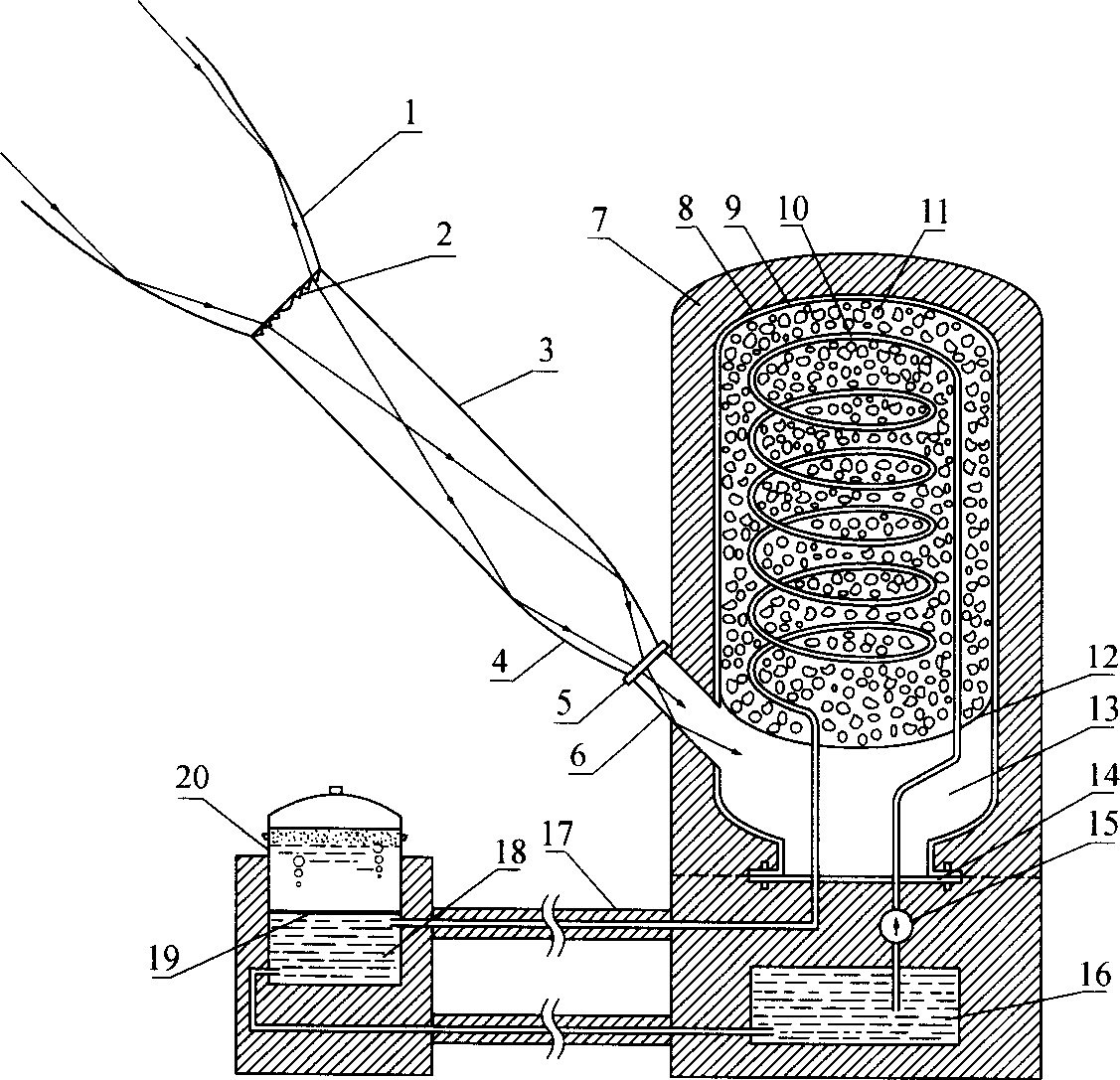

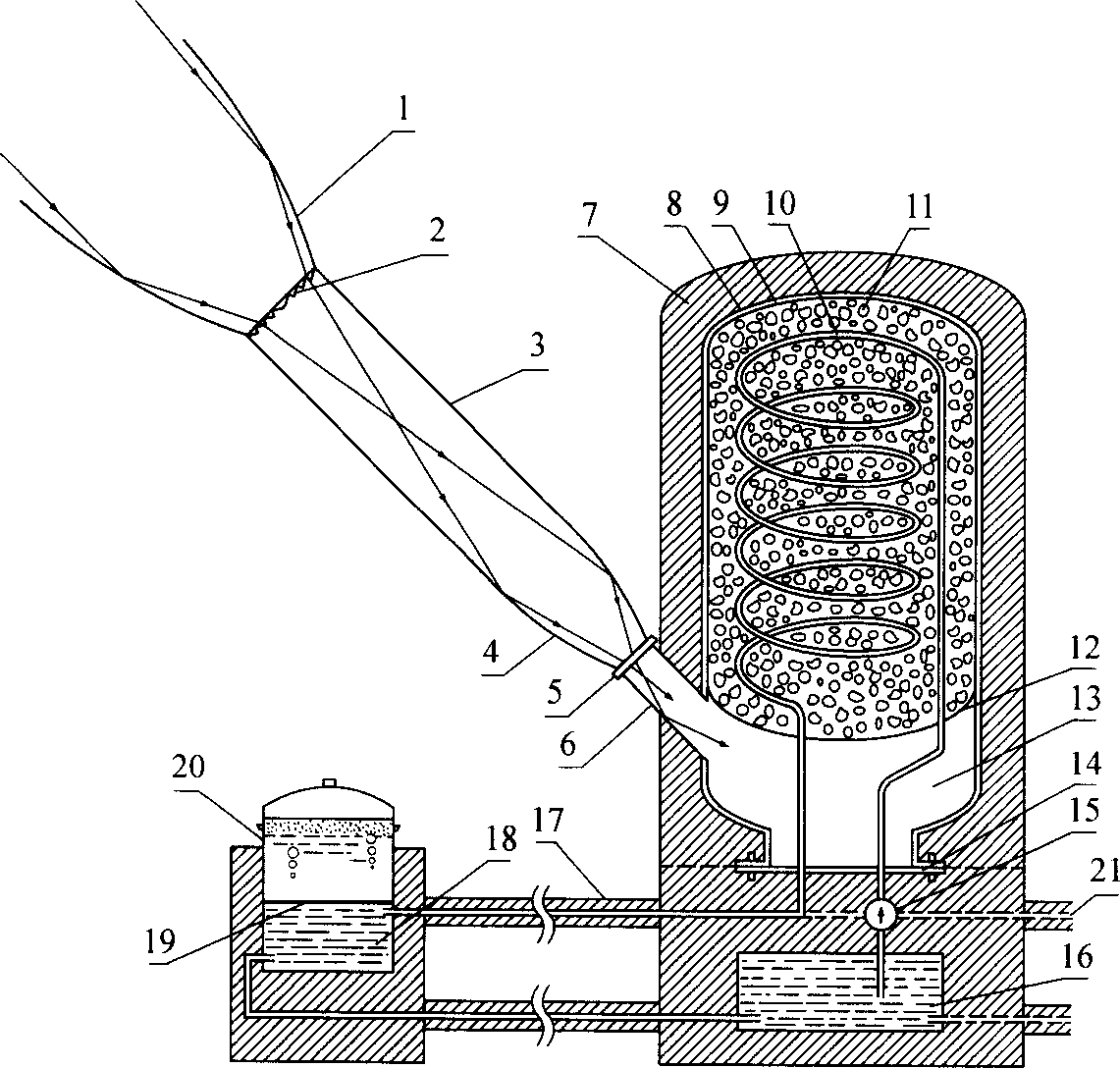

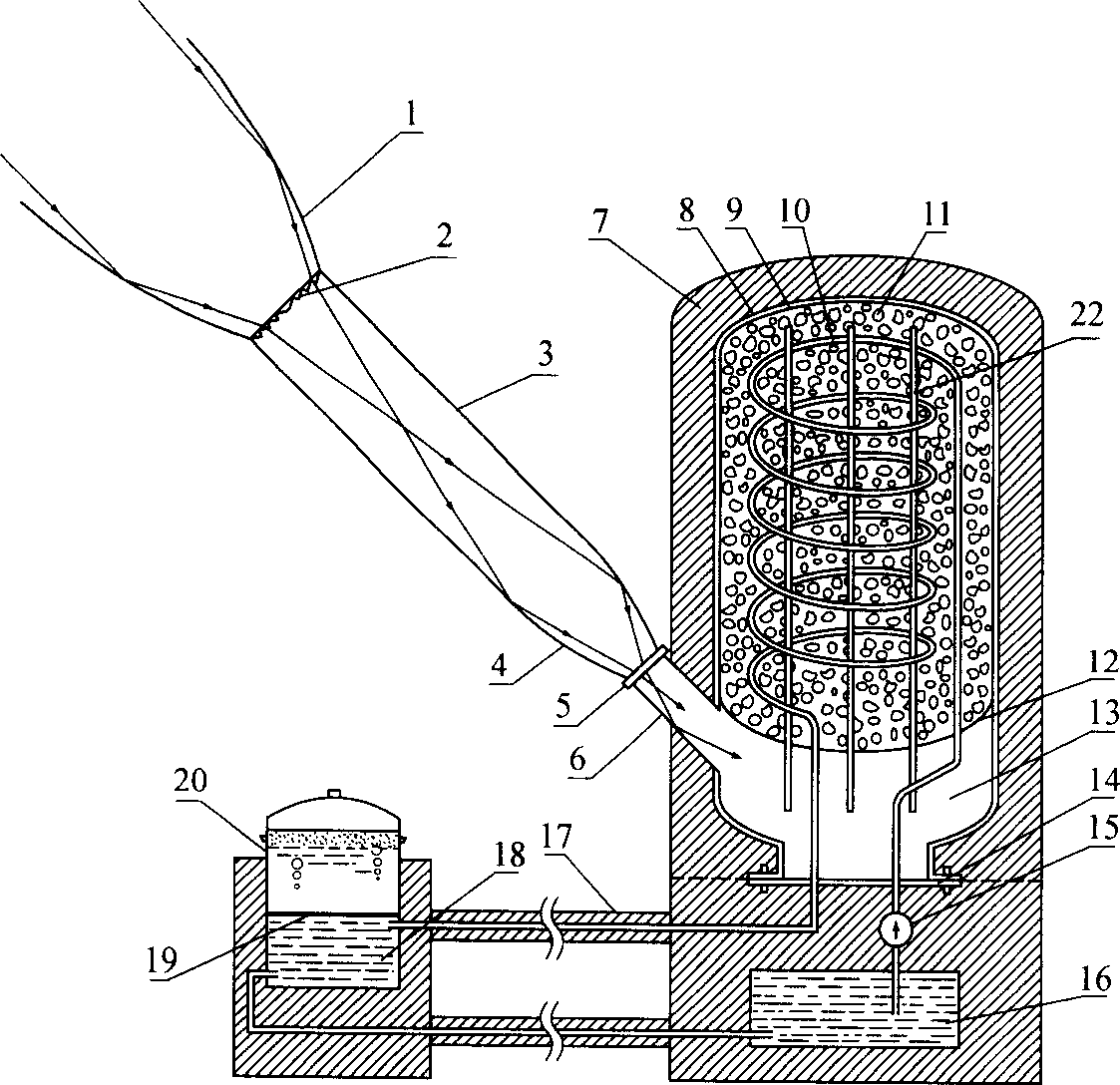

[0015] figure 1 It is a schematic diagram of the present invention. exist figure 1 , the operating principle of the device can be explained step by step as follows:

[0016] The invention is a device that can use the light funnel to introduce the concentrated sunlight, and use the high-temperature phase-change energy storage material to store heat, so as to realize the provision of high-temperature heat energy for users. During the operation of the device, sunlight is incident on the inner surface of the primary CPC (compound parabolic concentrator) (1), if the angle between the sunlight and the rotation axis of the primary CPC (1) is smaller than the concentrator half angle of lighting, the sunlight is reflected onto the Fresnel lens (2), and after being transmitted through the Fresnel lens (2), most of the sunlight is transformed into near-parallel light, which is transmitted in the light guide (3). transfer. The outlet of the light pipe (3) is connected to the inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com