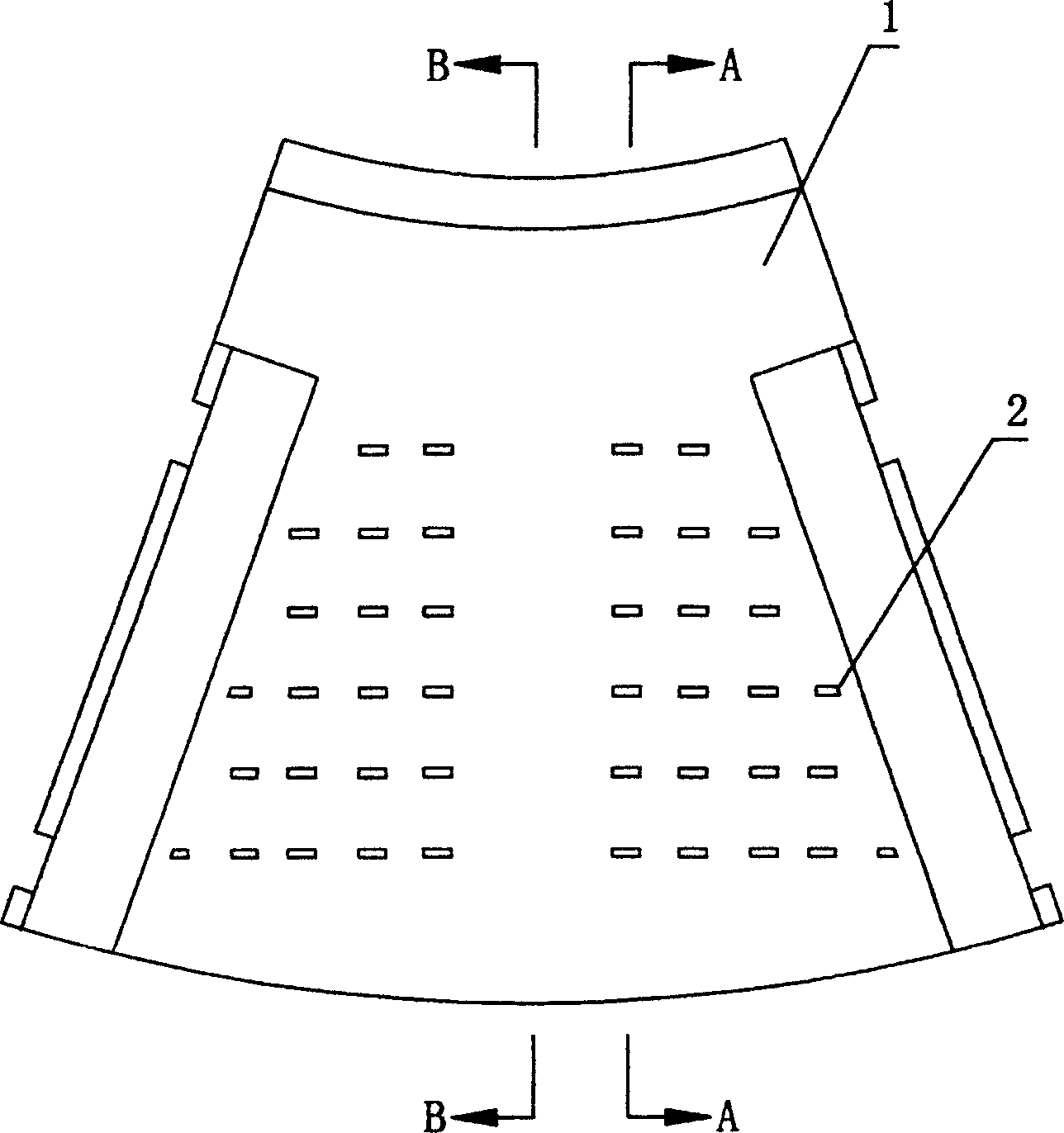

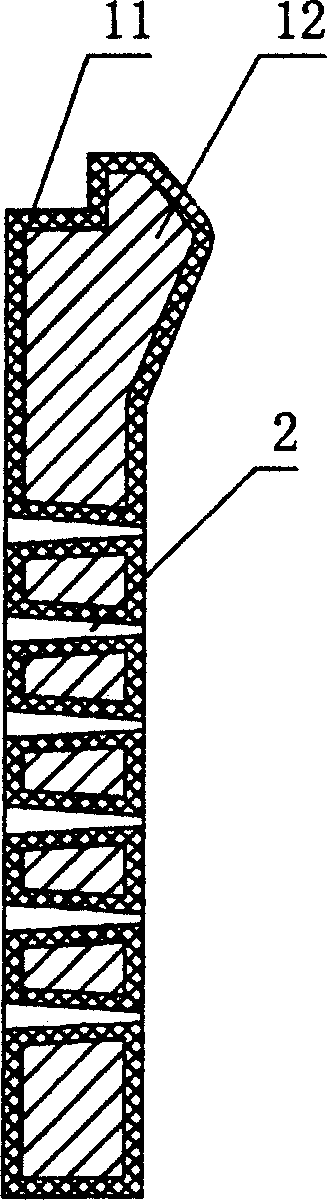

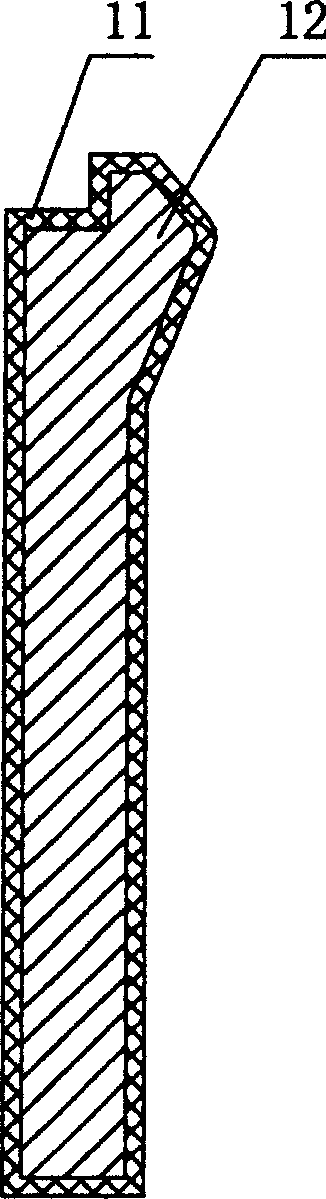

Composite grate plate for automatic mill

A composite lattice and autogenous mill technology, applied in grain processing and other directions, can solve the problems of product pollution, increased production cost, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Refer to Figure 4 In the figure, the grating plate 7 currently used is installed at the discharge end of the grinding cylinder 3 of the self-milling machine. The grating plate 7 is arranged in the circumferential direction of the grinding cylinder 3 to divide the grinding cylinder 3 into a material self-grinding space and row. In the discharging space, there are several dustpan plates 4 arranged along the circumference of the grinding cylinder 3 that can transport the quartz sand particles screened by the grating plate 7 to the discharge cylinder 5, because the grating plates currently used by people Most of the discharge holes are strip-shaped holes. There are some larger quartz sand particles in the quartz sand screened by the grid plate with strip-shaped discharge holes, so there is a self-returning screen in the discharge barrel 5. 6. The self-returning sieve 6 can transport the larger quartz sand particles back to the grinding cylinder 3 for self-grinding, while the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com