Method for manufacturing flake-like arc contact finger

A manufacturing method and sheet-like technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of easy melting of the solder layer, hidden dangers of accidents, low melting point, etc., and achieve the effects of high mechanical strength, material saving and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

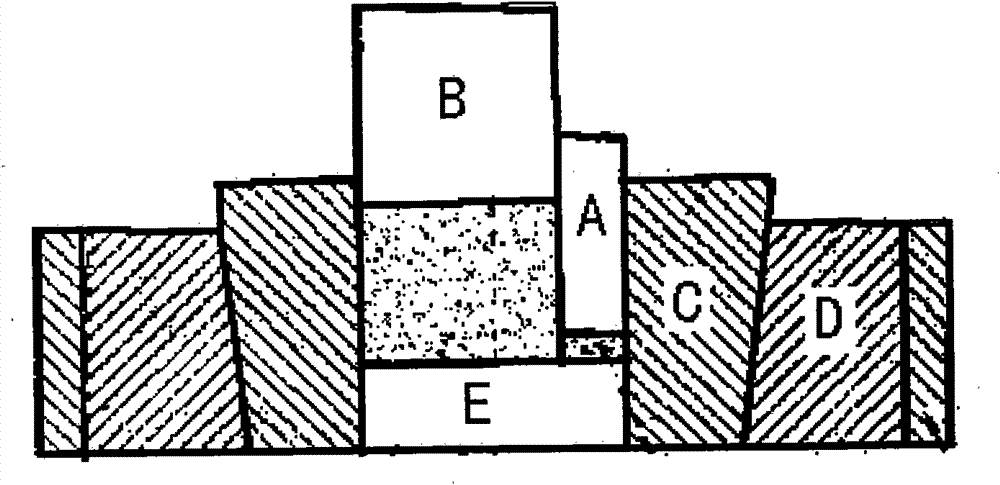

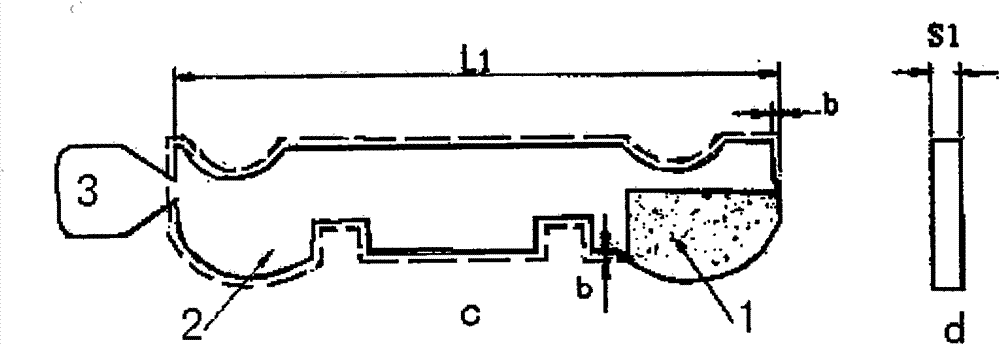

[0023] The invention provides a method for manufacturing a sheet arc contact finger. The present invention will be further described below in conjunction with the accompanying drawings. The manufacture of the sheet-shaped arc contact finger adopts two kinds of powder composite pressing, and the whole is carried out at a high temperature above the melting point of copper in an environment where the protective gas is an inert gas (nitrogen or argon) or a reducing gas hydrogen or a mixture thereof. Sintering, plastic deformation through recompression, pressure processing to improve the physical and mechanical properties of copper, and finally plane processing to obtain sheet arc contact fingers;

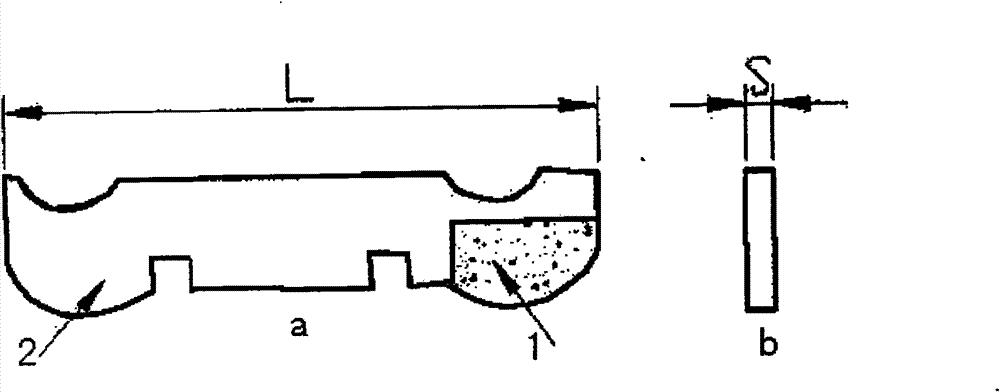

[0024] figure 1 Shown is a schematic diagram of the structure of the sheet arc finger, where a. the front view of the sheet arc finger; b. the side view of the sheet arc finger. The manufacturing process steps of the flake arc contact finger are as follows:

[0025] (1) Ingredients, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com