Cavity cleaning method for semiconductor etching equipment

A technology for etching equipment and semiconductors, applied in the direction of cleaning methods using gas flow, cleaning methods and utensils, semiconductor/solid-state device manufacturing, etc., can solve the problems of expensive molecular pumps, reduce the service life of molecular pumps, etc., and achieve reduced time , to ensure normal operation and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

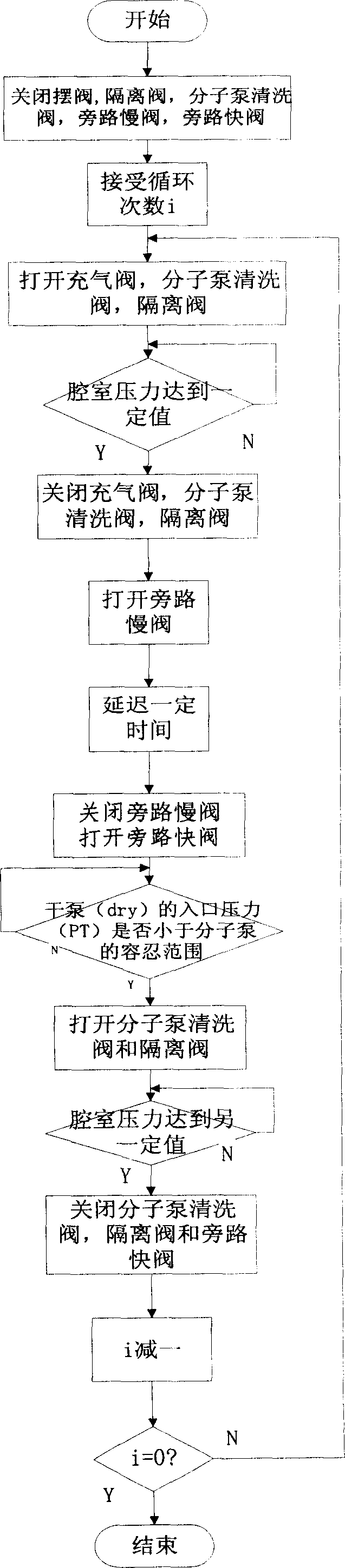

[0027] The specific implementation of the chamber cleaning method for semiconductor etching equipment of the present invention will be further described in detail below in conjunction with the accompanying drawings, but it is not used to limit the protection scope of the present invention.

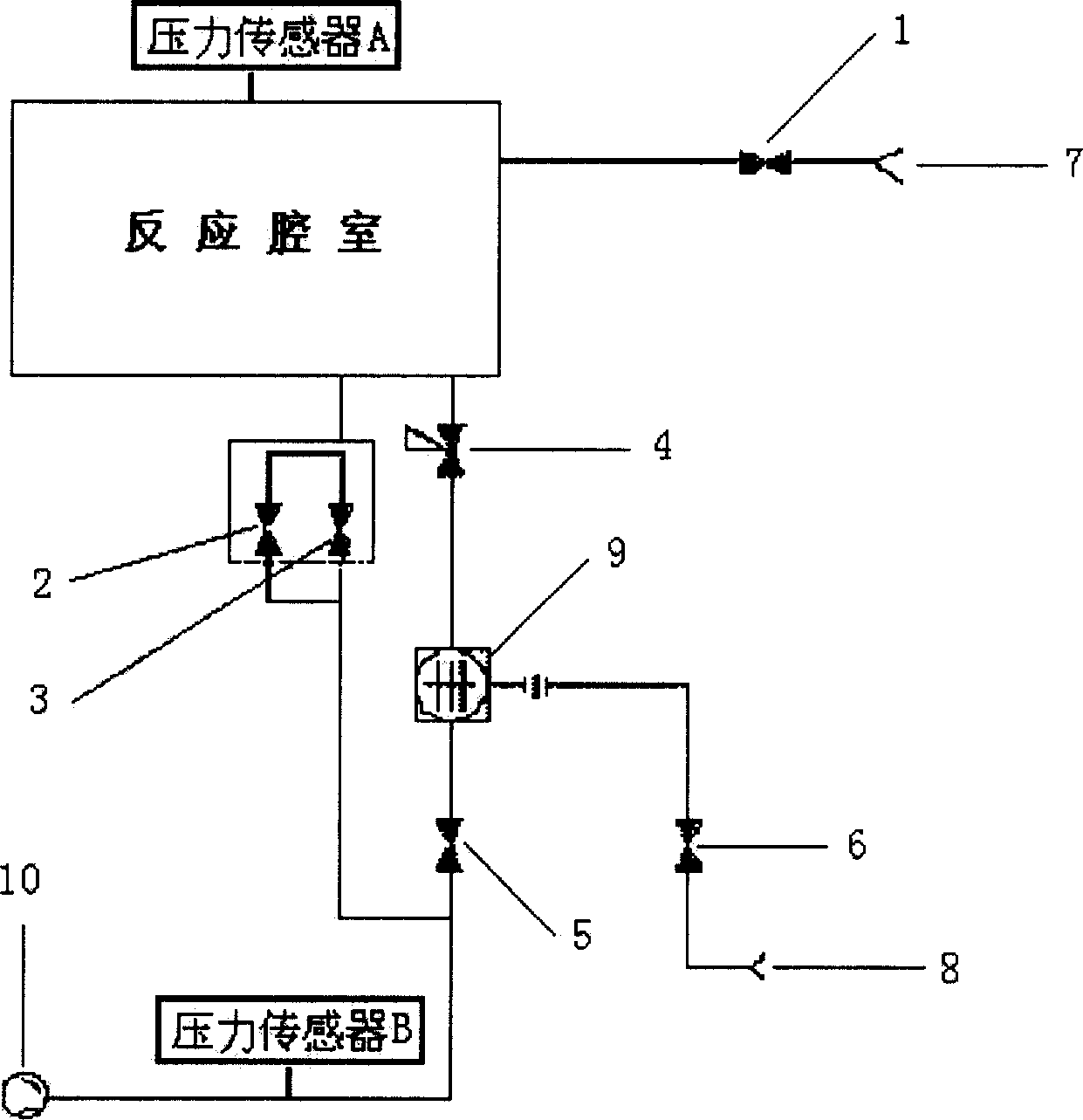

[0028] see figure 1 , the etching equipment chamber cleaning method proposed by the present invention, wherein, there are 6 valves around the reaction chamber, which are respectively an inflation valve 1, a side pumping slow valve 2, a side pumping block valve 3, a swing valve 4, and a molecular pump isolation valve 5. Molecular pump cleaning valve 6, these valves are used to control the air flow in the chamber and provide a certain load for the molecular pump 9; in addition, it is necessary to use a pressure sensor A in the chamber to determine how much gas is filled in the inflation valve, whether it is Reaching a sufficient air pressure, that is, how much it can evenly dilute the pollut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com