Weak-magnetic driving apparatus of permanent magnet brush-less DC. motor

A permanent magnet brushless DC, magnetic drive technology, applied in the direction of torque ripple control, etc., can solve the problems of torque reduction, weak magnetic field speed-up range and other problems, and achieve the elimination of circulating current, improved operation performance and small torque ripple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

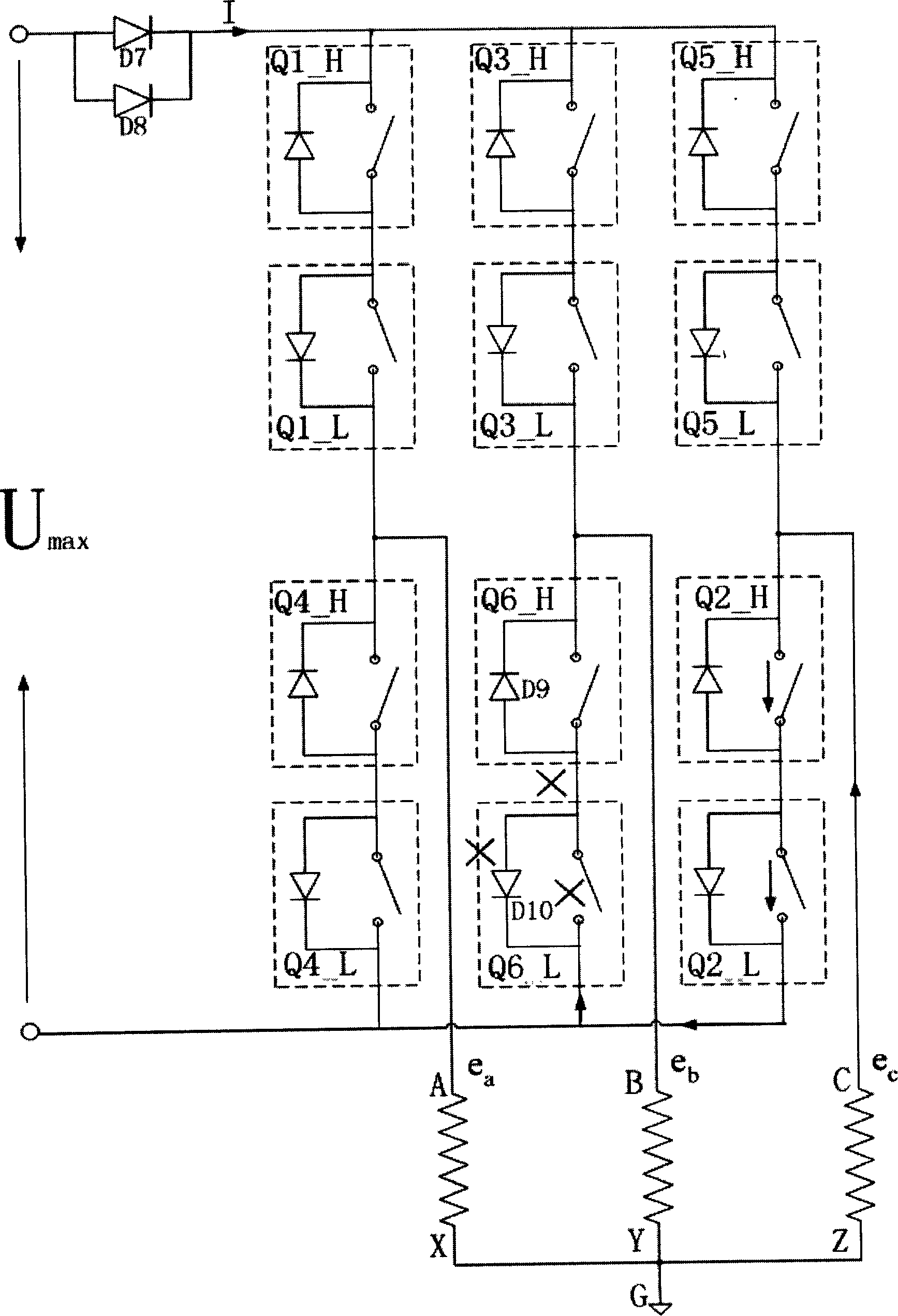

[0025] The embodiment of the present invention is a 28V field weakening drive device. like Figure 4 shown. MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) adopts IRFP460, and a pair of MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) S poles (sources) of each bridge arm are connected, and the connected ground is suspended. The G poles (gates) of Q1_H and Q1_L are connected and triggered simultaneously by T1; the G poles (gates) of Q3_H and Q3_L are connected and triggered by T3 simultaneously; the G poles (gates) of Q5_H and Q5_L are connected and triggered simultaneously by T5 , the G poles (gates) of Q4_H and Q4_L are connected, and are triggered simultaneously by T4; the G poles (gates) of Q6_H and Q6_L are connected, and are triggered by T6 at the same time; trigger. Connect a transient voltage suppressor D1, D3, D5, D4, D6, D2 in parallel to the MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) Q1_L, Q3_L, Q5_L, Q4_L, Q6_L, and Q2_L under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com