Production of glass micropearl reflecting-film and single-layer coplanar tree

A technology of glass microbeads and reflective film, used in optics, optical components, instruments, etc., can solve the problems of inability to arrange closely, waste raw materials, affect reflective brightness, etc., and achieve improved appearance, uniform surface, and enhanced reflective strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

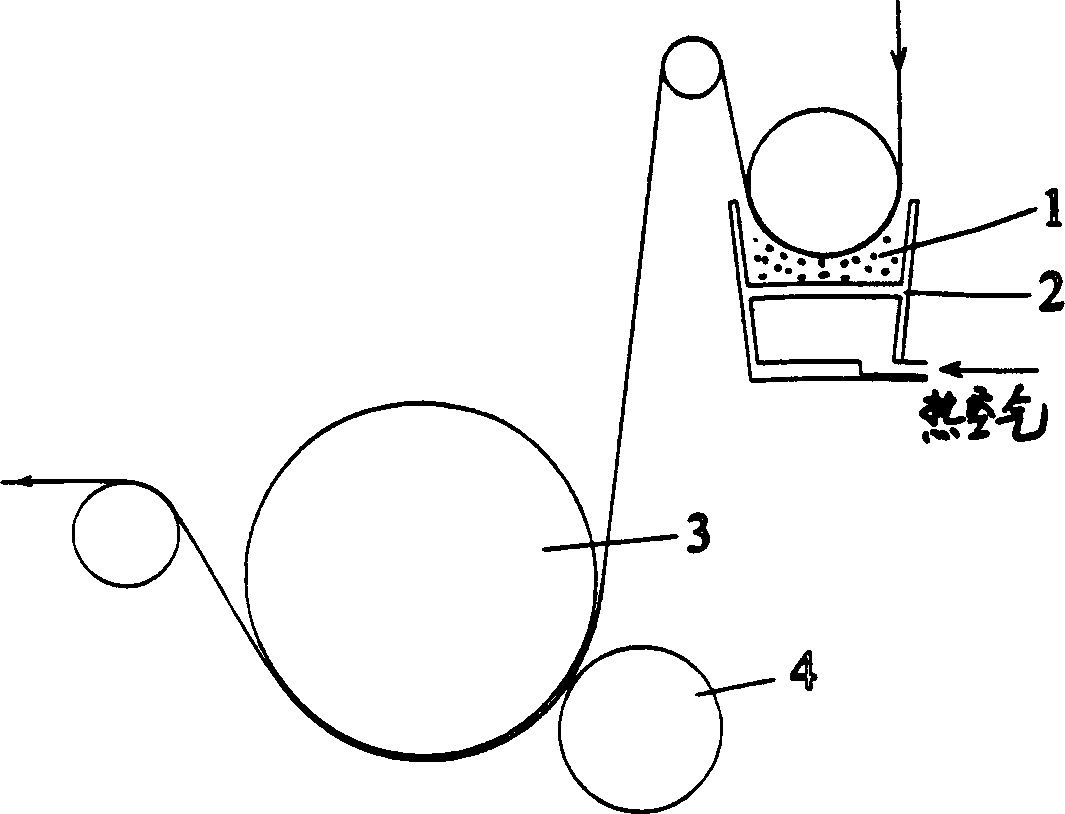

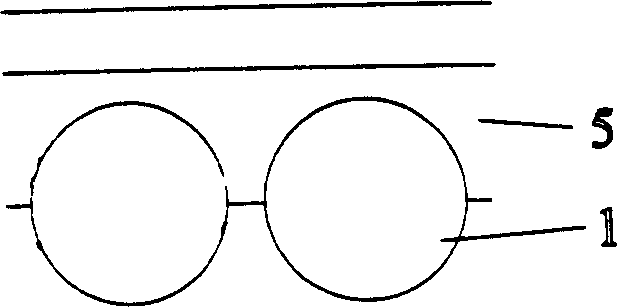

[0015] Such as figure 1 As shown, the glass beads 1 preheated to 80-90°C by an oven are put into the fluidized bead tank 2, separated by a gas-permeable plate in the middle, and uniform pores are distributed on the plate, and the pore diameter is smaller than the diameter of the smallest glass beads . An electrostatic device is used to positively charge the film passing roller and negatively charge the glass beads 1 . Hot air at 80° C. is blown in from the bottom of the fluidized bead tank 2 to make the glass beads adhere to the surface of the adhesive layer 5 . After the hot-composite steel roller 3 and the rubber roller 4 are pressed together, the hot-press temperature of the hot-compound steel roller 3 is 60-70°C, and the air pressure is controlled at 0.3-0.35MPa, so that the glass beads 1 are evenly and tightly distributed on the surface of the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com