Method for producing semiconductor imaging sensor by organic coating

An image sensor and organic coating technology, used in the field of manufacturing semiconductor image sensors, can solve problems such as poor development, affecting color pixel performance, excessive noise, etc. The effect of improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

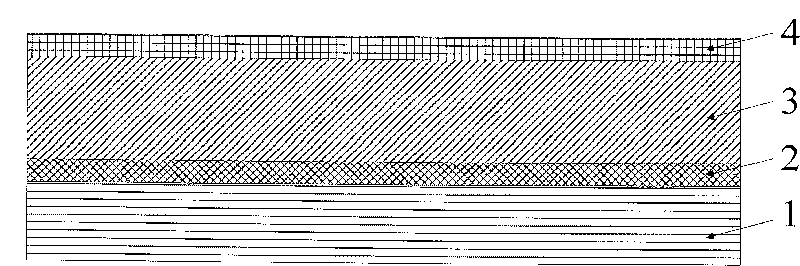

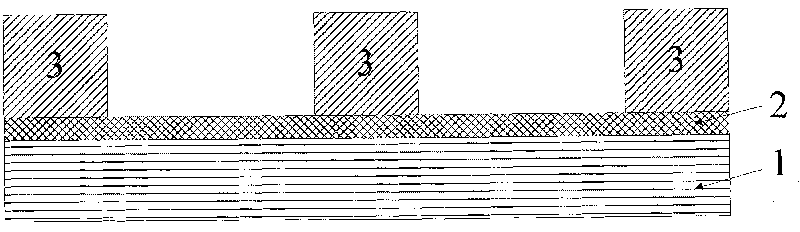

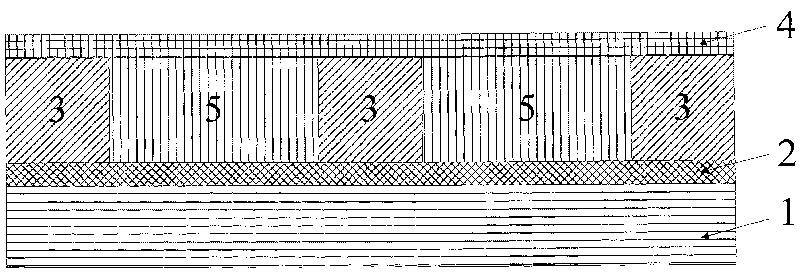

[0036] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] Firstly, the substrate is cleaned, and a bottom anti-reflection development strengthening layer is coated on the surface of the substrate. The coating thicknesses are 60nm, 70nm, 80nm, 90nm, 100nm, 110nm and 120nm respectively, the baking temperatures are 180°C, 200°C and 220°C respectively, and the baking times are 60 seconds, 70 seconds, 80 seconds and 90 seconds respectively and 100 seconds, by coating the bottom anti-reflective development strengthening layer to reduce the reflected light of the base and enhance the development performance.

[0038] Next, coat the red light pixel semiconductor image sensor filter layer material on the bottom organic material, the coating thickness is 1000nm, 1100nm, 1200nm, 1300nm, 1400nm or 1500nm, and the baking temperature is 180°C, 200°C or 220°C , the time is 60 seconds, 70 seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com