Composition for forming etching stopper layer

An etching stop layer, composition technology, applied in coatings, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as changing production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

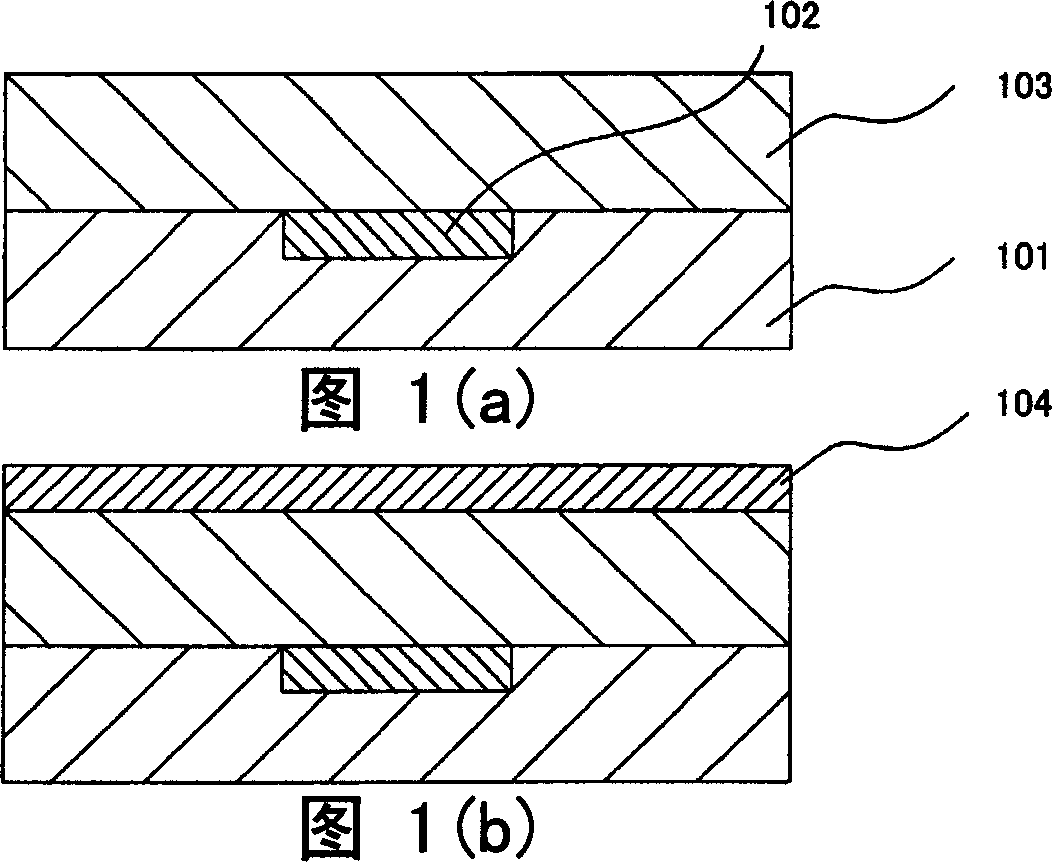

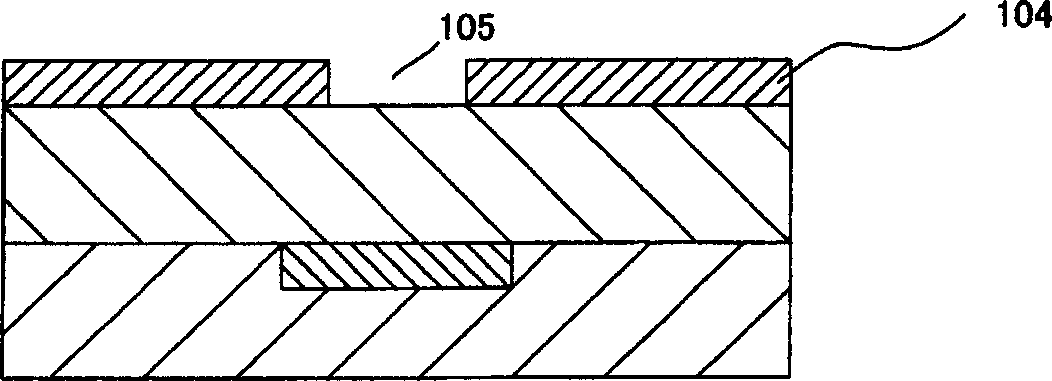

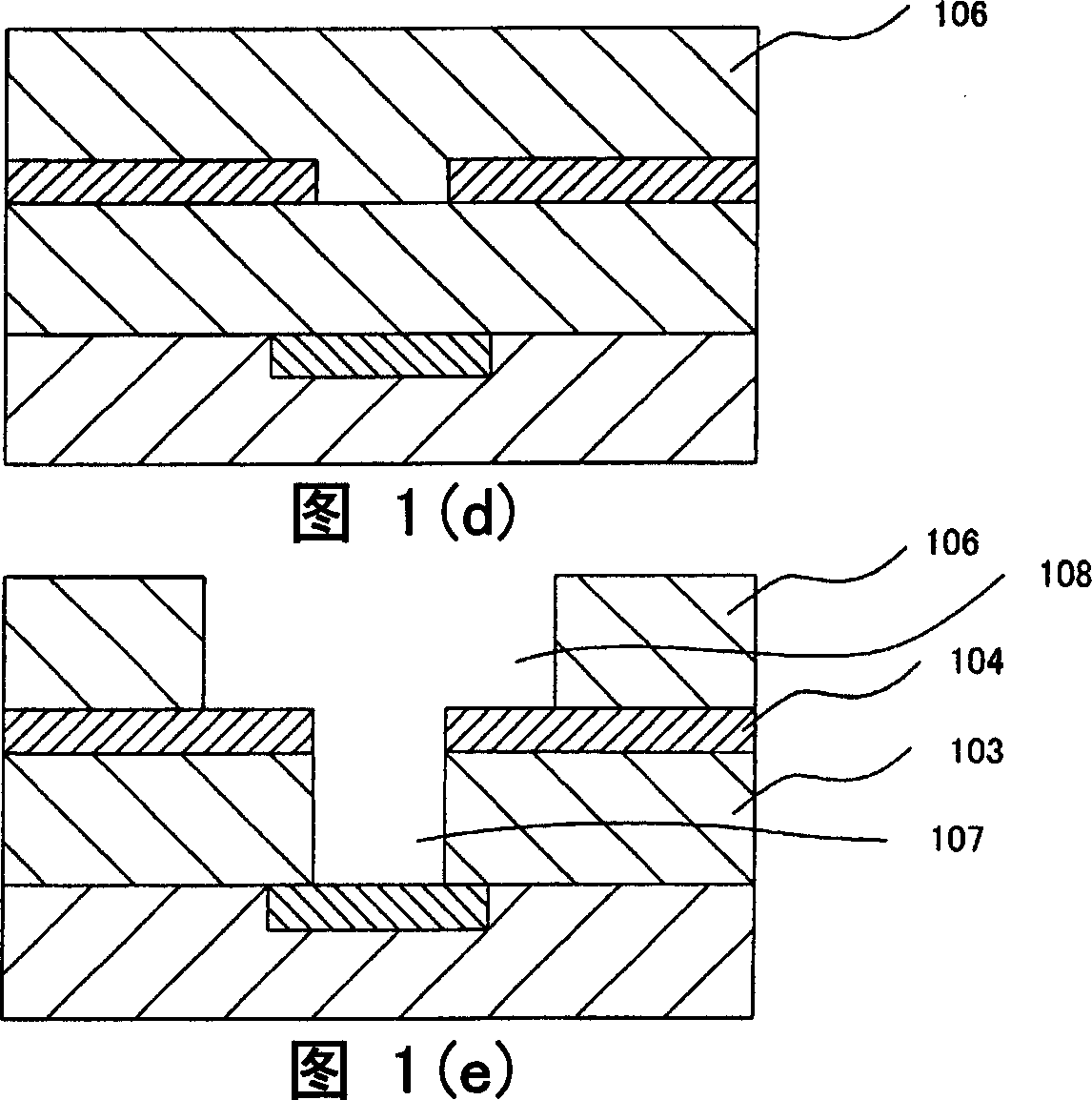

Method used

Image

Examples

Synthetic example 1

[0073] In addition to using 105.75g of phenyltrichlorosilane (PhSiCl 3 ) and 39.4g of 1,4-bis(dimethylchlorosilyl)benzene were synthesized in the same manner as Comparative Synthesis Example 1 except that the starting materials were used. As a result, about 63 g of highly viscous polymer 1 was obtained.

[0074] The molecular weight of Polymer 1 was measured. As a result, the number average molecular weight was 1500, and the weight average molecular weight was 4000.

[0075] The FT-IR of this polymer 1 was measured. As a result, in addition to the absorption observed in the polymer A prepared in Comparative Synthesis Example 1, there was also an absorption at 780 cm -1Absorption attributed to adjacent hydrogens in the benzene ring was observed nearby. The adjacent hydrogens in the benzene ring come from 1,4-bis(dimethylchlorosilyl)benzene, that is to say the disilylbenzene structure. Observations indicated that 1,4-bis(dimethylchlorosilyl)benzene was incorporated into Pol...

Synthetic example 2

[0077] The air in the reaction vessel installed in the thermostatic chamber was replaced with dry nitrogen. Then, dissolved in 1000ml xylene, made of 47g phenyltrichlorosilane (PhSiCl 3 ), 56g diphenyldichlorosilane (Ph 2 SiCl 2 ), 3.8g methyldichlorosilane (MeSiHCl 2 ), and a solution consisting of 50 g of 1,4-bis(dimethylchlorosilyl)benzene was introduced into the reaction vessel. Next, the internal temperature of the reaction vessel was set to -5°C. When the temperature of the solution reached a predetermined temperature, a mixed solution consisting of water and pyridine prepared by dissolving 13 g of water in 1000 ml of pyridine was introduced into the reaction vessel at a rate of about 30 ml / min. In this case, at the time of introduction of the mixed solution, a reaction of halosilane and water occurred, and, thereby, the internal temperature of the container rose to -2°C. After the introduction of the mixed solution consisting of water and pyridine was completed, th...

Synthetic example 3

[0080] Polymer 3 having a disilylbenzene structure was synthesized in the same manner as in Synthesis Example 2 except that 66.3 g of methyltrichlorosilane was used instead of phenyltrichlorosilane and diphenyldichlorosilane. In Polymer 3, the silicon content in the disilylbenzene structure was 28.5 mol % based on the total moles of silicon contained in Polymer 3 . The carbon content in polymer 3 was 25% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com