Power device using thermal energy of exhaust gas

A power plant and thermal energy technology, applied in exhaust devices, mufflers, engine components, etc., can solve the problems of thermal energy waste, huge energy consumption of internal combustion engines, etc., and achieve the effects of reducing noise, reducing maintenance time, and reducing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

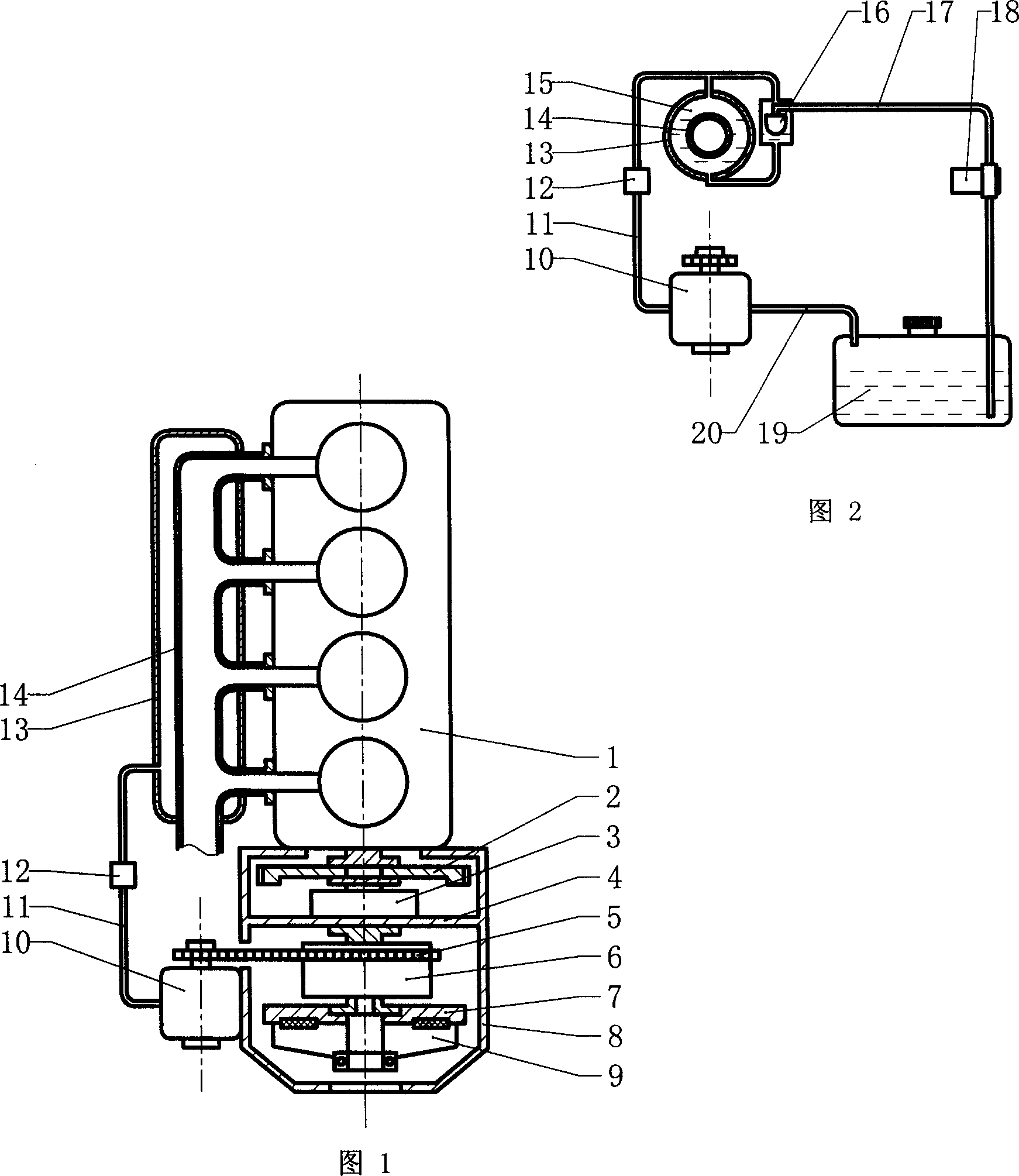

[0012] Below in conjunction with accompanying drawing, the embodiment and working principle of the device of the present invention are described further in detail, Fig. 1 and Fig. 2 have shown the implementation and the principle of control of the waste gas heat energy power device of the present invention, and this device is to set up on the original vehicle engine A set of additional power equipment is generally composed of a boiling water control part, a power generation and a power merging part. Boiler 15 is a pressure vessel for boiling water, and a sealed tank is formed by boiler shell 13 and exhaust pipe 14, and water is housed in the cavity between boiler shell 13 and exhaust pipe 14. , the water in the water storage tank 19 is extracted by the high-pressure water pump 18, and the water is sent into the water boiler 15 through the water inlet pipe 17 and the water level controller 16, and the water capacity of the water boiler 15 and the height of the water surface are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap