Low-voltage arc quenching system based on wall erosion to improve pneumatic repellent force and break performance

A device wall, low-voltage technology is applied in the field of devices that use gas-producing materials to improve the pneumatic repulsion and breaking performance of low-voltage electrical appliances, and can solve the problem of not effectively improving the current-limiting performance of low-voltage circuit breakers, unfavorable product miniaturization and reliability, and increasing Processing difficulty and other problems, to achieve the effect of suppressing the phenomenon of contact falling, preventing contact falling and welding, and improving the breaking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings.

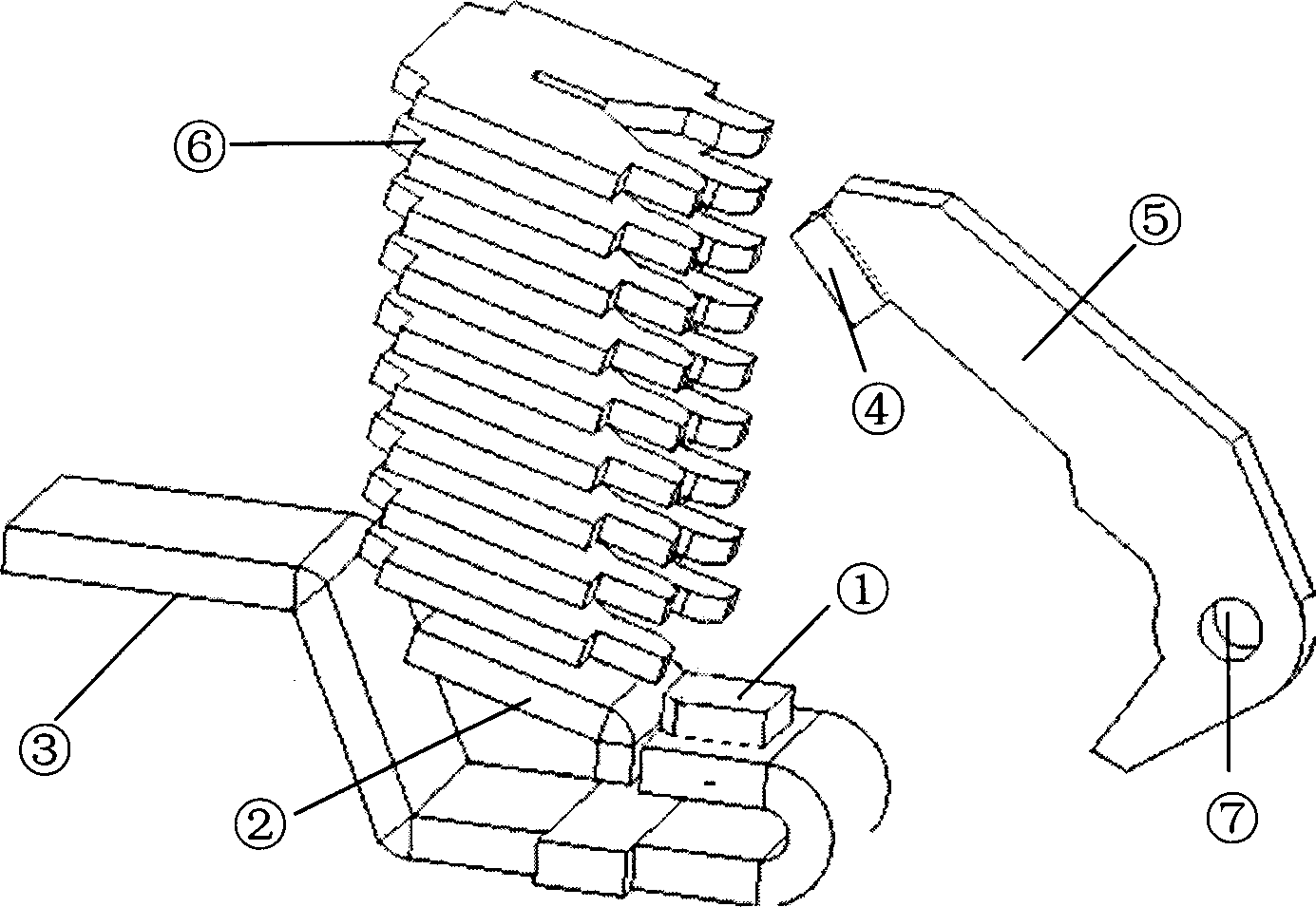

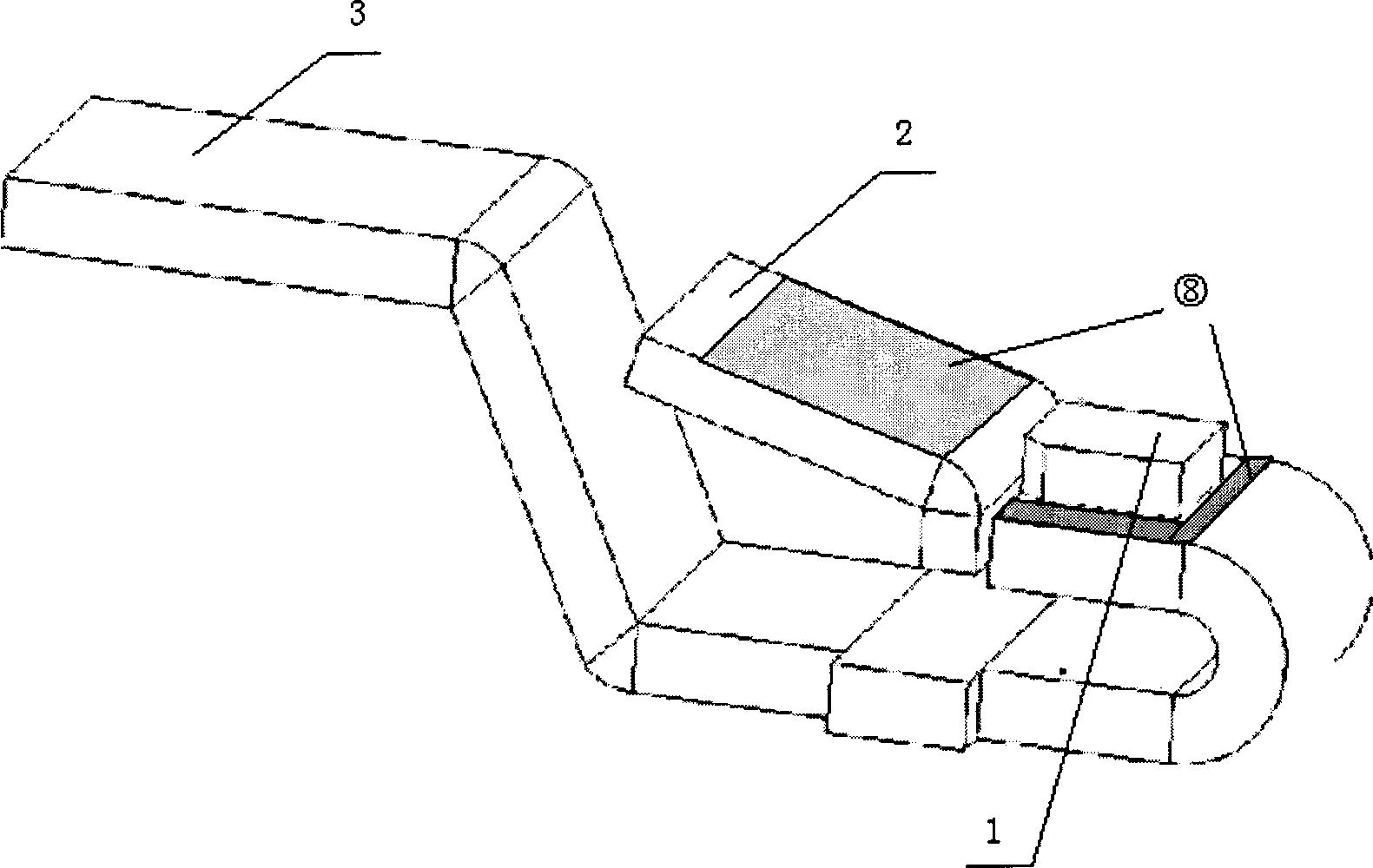

[0019] See figure 1 , 2. The present invention includes an arc ignition plate 2 and a static conductive system 3 connected with the arc ignition plate 2. A static contact 1 is fixed on the upper end surface of the arc ignition plate 2, and the upper end of the arc ignition plate 2 is also provided There is an arc extinguishing chamber 6, a movable conductive rod 5 matched with the static contact 1 is provided on one side of the arc extinguishing chamber 6, and the movable conductive rod 5 is fixed by a rotating shaft 7, and a movable conductive rod 5 is also provided at the front end of the movable conductive rod 5. The contact 4 is provided with a gas generating material layer 8 made of MMA, POM, PBT or nylon material around the static contact 1 and on the arc-igniting plate 2 respectively.

[0020] See figure 1 , 2. The present invention includes a static conductive circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com