Self-operated method and system for removing group of bottle from container

A self-supporting, self-gravity technology, applied in the direction of packaging bottles, packaging, packaging items, etc., can solve the problems of increased power consumption and air consumption, mechanical wear, high center of gravity, etc., to save working time, reduce mechanical wear, fast falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

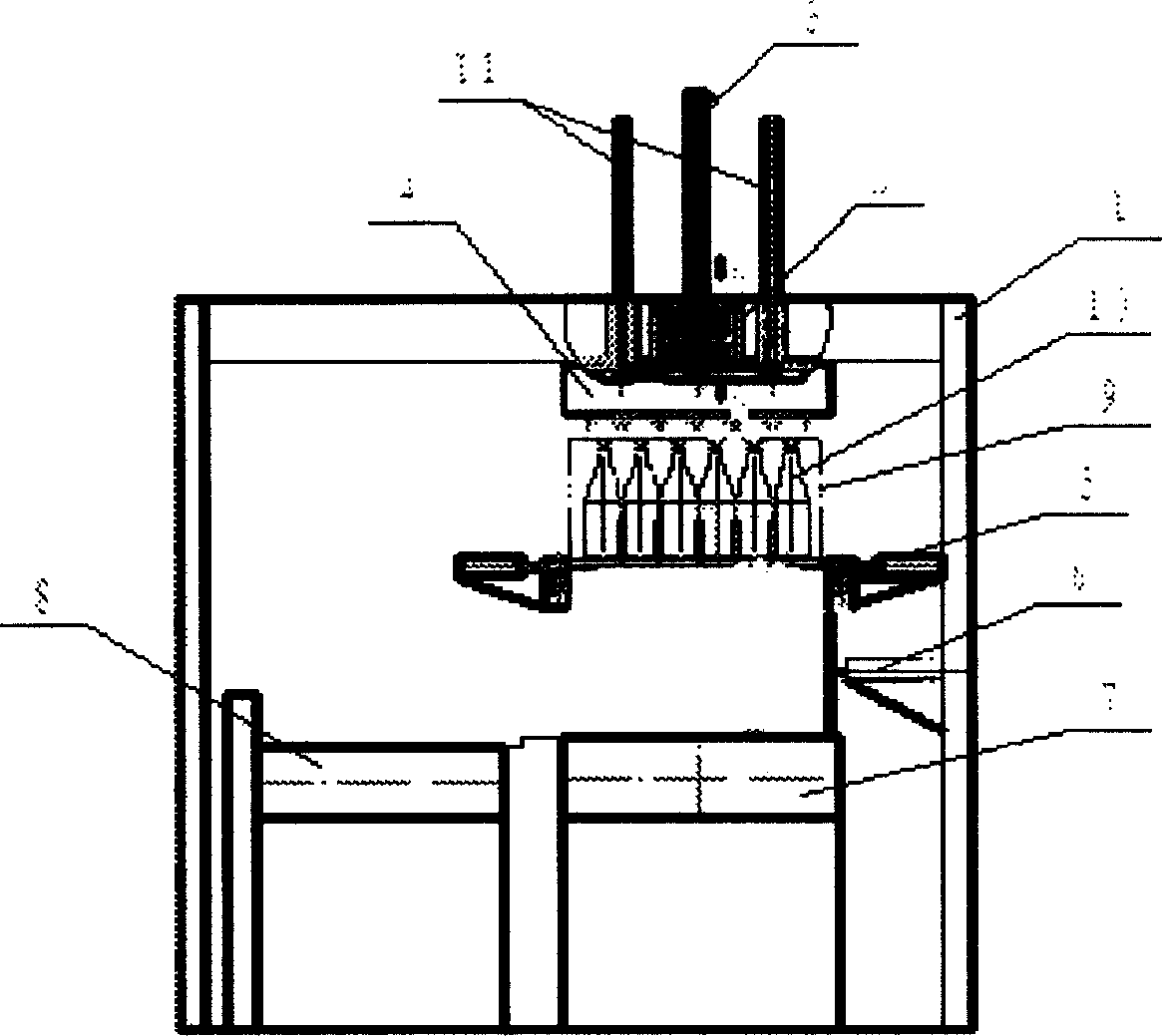

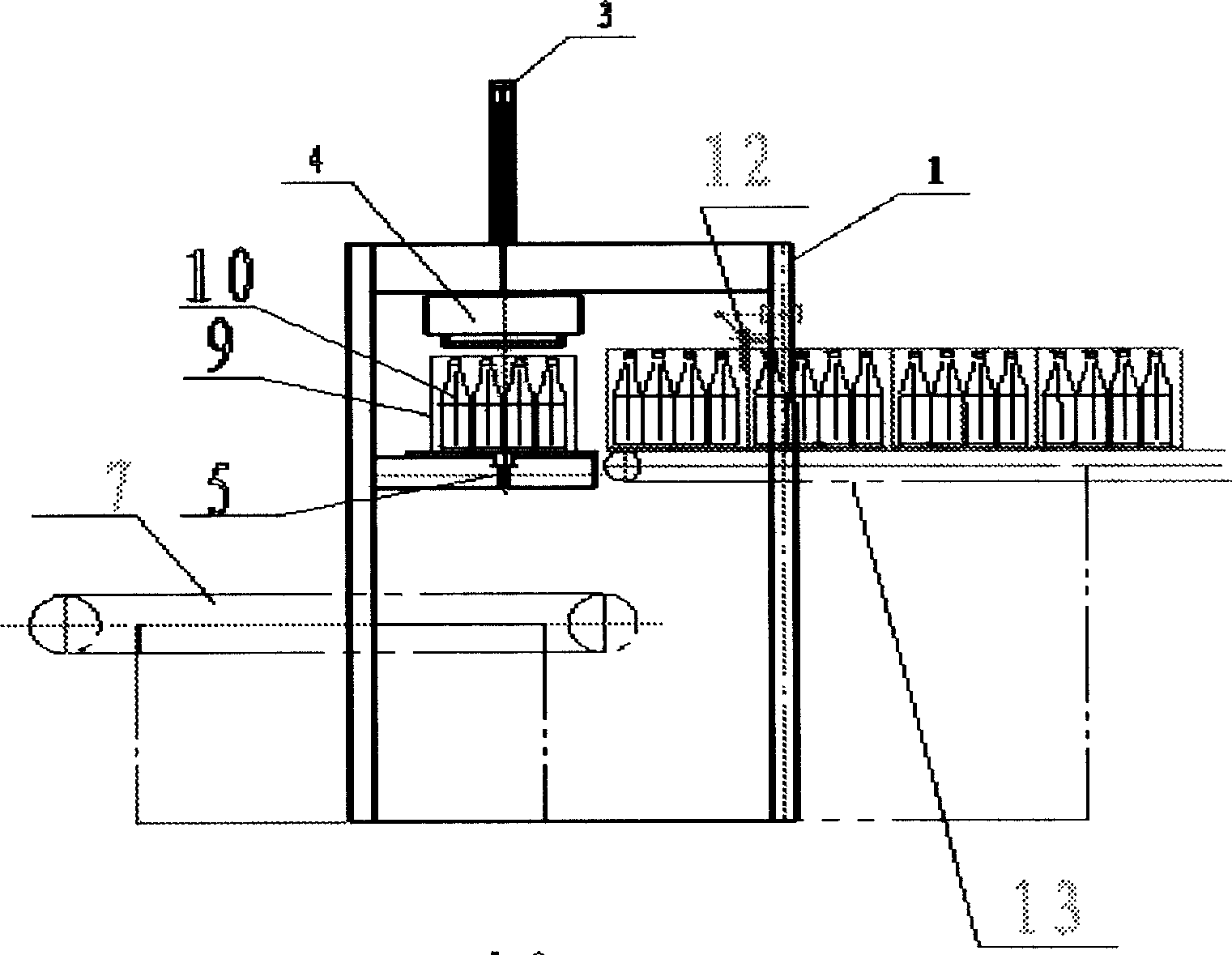

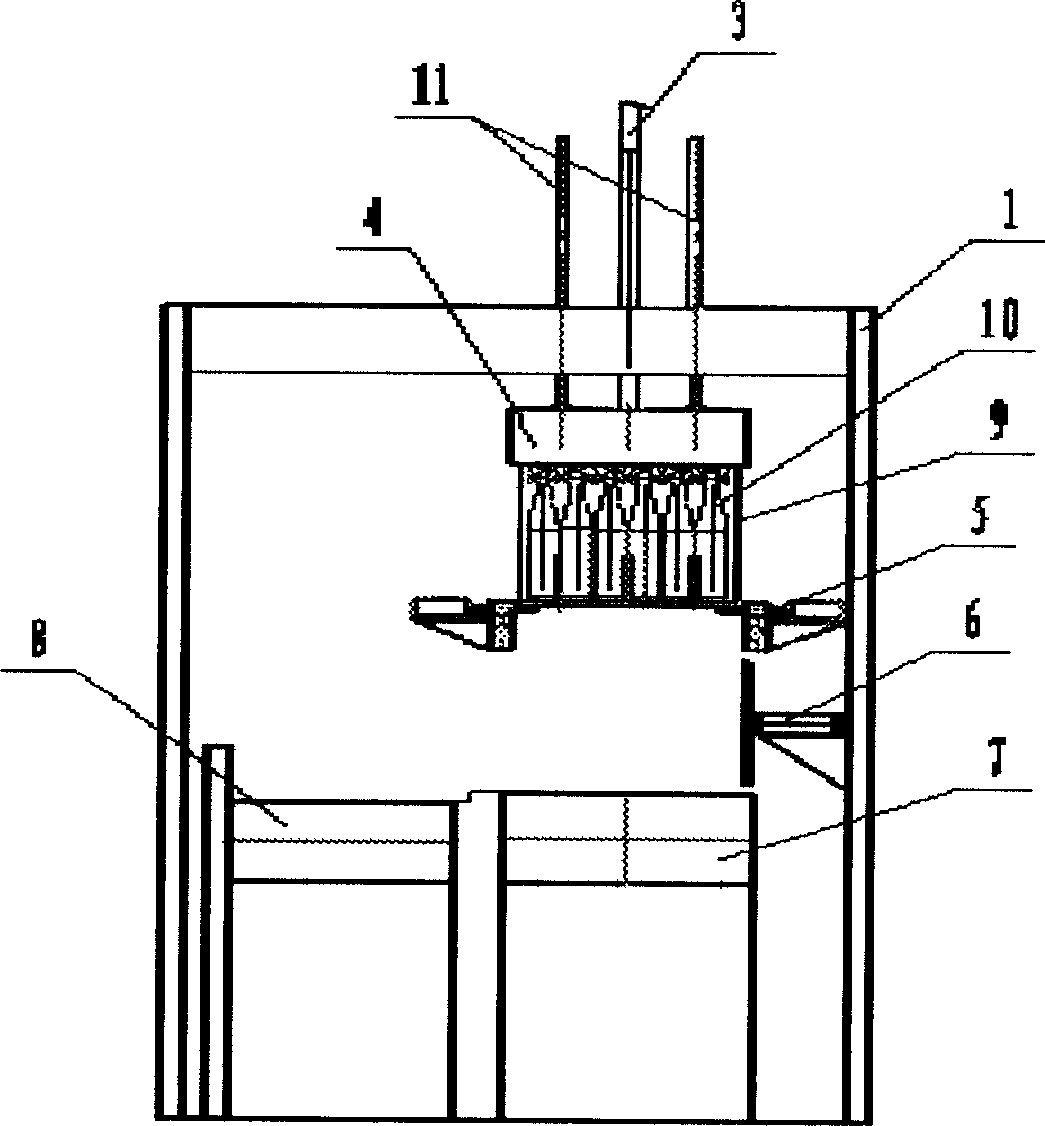

[0028] like Figure 1 to Figure 9As shown, in the initial state, the clamping mechanism 4 is located at a high position due to the lifting power or supporting force of the lifting device 3, and the box 9 carrying the container 10 to be unloaded enters the drop box device 5 directly below the clamping mechanism 4 After reaching the predetermined position on the top, the lifting device 3 releases the lifting power or supporting force to the clamping mechanism 4, so that the latter falls on the predetermined position on the container 10 to be unloaded in the box by its own weight and clamps the container 10. At the same time, the clamping Mechanism 4 is once again suspended at this position by a supporting force of lifting device 3; after container 10 is clamped, at first the container 10 is completely separated from the box 9 by automatically falling off the empty box 9, and the container 10 is completely separated from the box 9 by pushing the empty box mechanism 6. Case 9 push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com