Pump

A technology for pump chambers and casings, applied in pumps, pump devices, pump components, etc., can solve problems such as cracks and water leakage in the pump 100, and achieve the effects of increasing durability, improving water pressure resistance, and eliminating water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

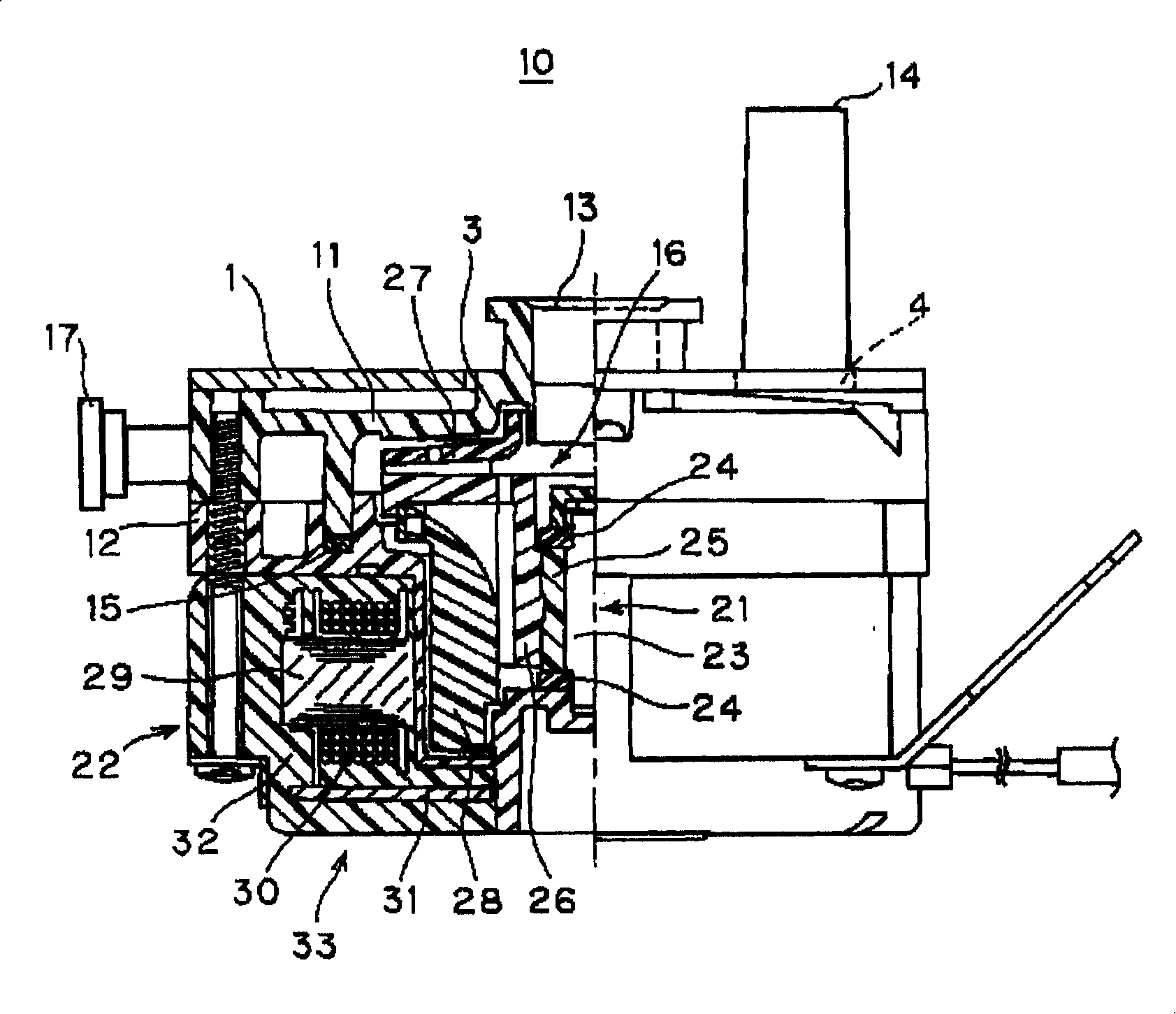

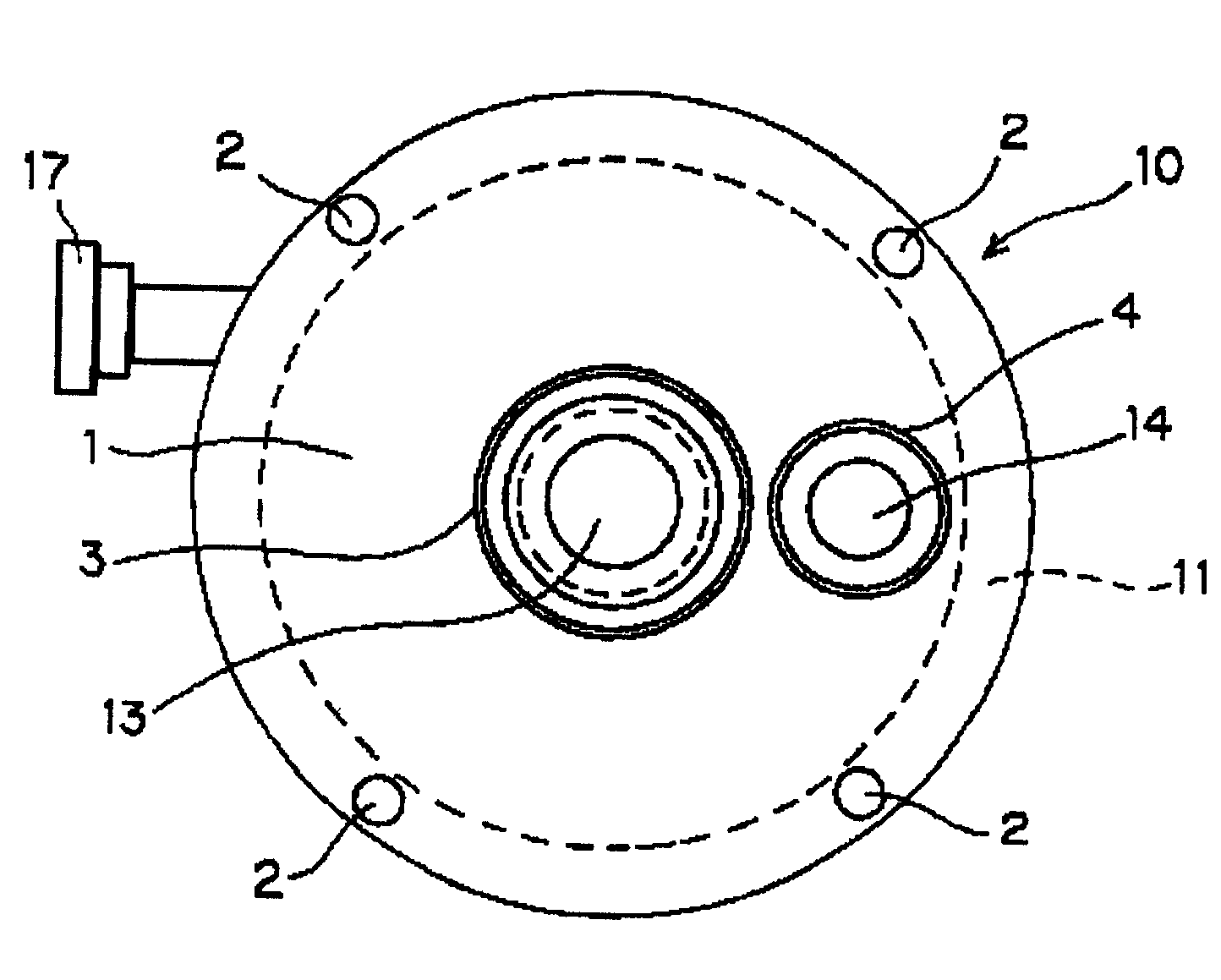

[0035] figure 1 is a longitudinal half-sectional view showing the pump 10 of the first embodiment; figure 2 is its top view. Such as figure 1 , 2 As shown, the pump 10 is a waterproof pump, and the rotor 21 is arranged inside the casing between the upper and lower casings 11 and 12 made of synthetic resin, and a ring is arranged along the outer periphery of the rotor 21. Shaped stator 22, thereby constituting the motor of the pump 10.

[0036] The upper and lower casings 11, 12 seal the inside of the pump 10 with packing 15 in between. The pump chamber 16 is arranged in the upper space in the casing. 14 protrudes from the housing 11 and is integrally formed with the housing 11 .

[0037] The rotor 21 is rotatably supported on a fixed shaft 23 at the center of the pump 10 inside the casing via a rotating shaft 25 and thrust washers 24 arranged above and below the rotating shaft 25, and the fixed shaft 23 is fixed on the upper , Between the lower housing 11,12.

[0038...

no. 2 approach

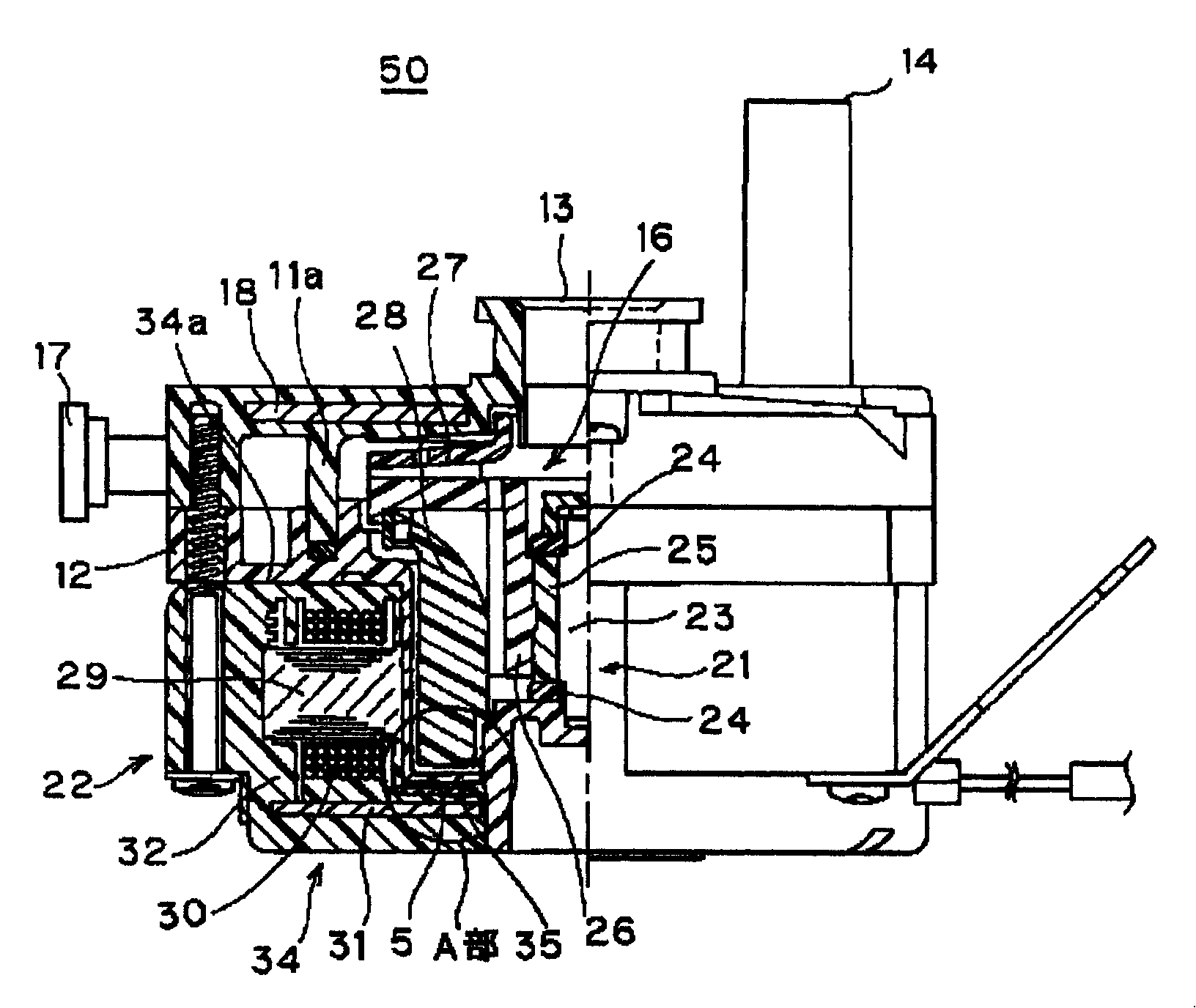

[0048] image 3 It is a half sectional view showing the pump 50 of the second embodiment, Figure 4 yes image 3 Enlarged view of part A in . Such as image 3 , Figure 4 As shown, the pump 50 is a waterproof pump having the same main structure as the pump 10 in the first embodiment. exist image 3 , for the same components as given with figure 1 The same reference numerals are used, and the description of the structure of the pump 50 is omitted.

[0049] In the pump 50 of the second embodiment, the stator 22 constituted by the annular laminated iron core 29 and the winding 30 is molded together with the printed circuit board 31 in the molding resin 32, thereby forming an annular resin molding. body34.

[0050] The resin molded body 34 is embedded with a ring-shaped molded part of the molded resin 32a between the base plate 31 on the outside of the cup-shaped bottom 35 of the case 12 and a part of the contact part with the case 12, that is, the part of the molded resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com